Lead-acid battery electrode grid and its manufacturing process

A lead-acid battery and electrode plate technology, applied in the direction of electrode carrier/current collector, etc., can solve the problems of low production efficiency, failure to achieve high rate charge and discharge, waste of energy, etc., to achieve small battery space occupation and save grid consumption. Lead content, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

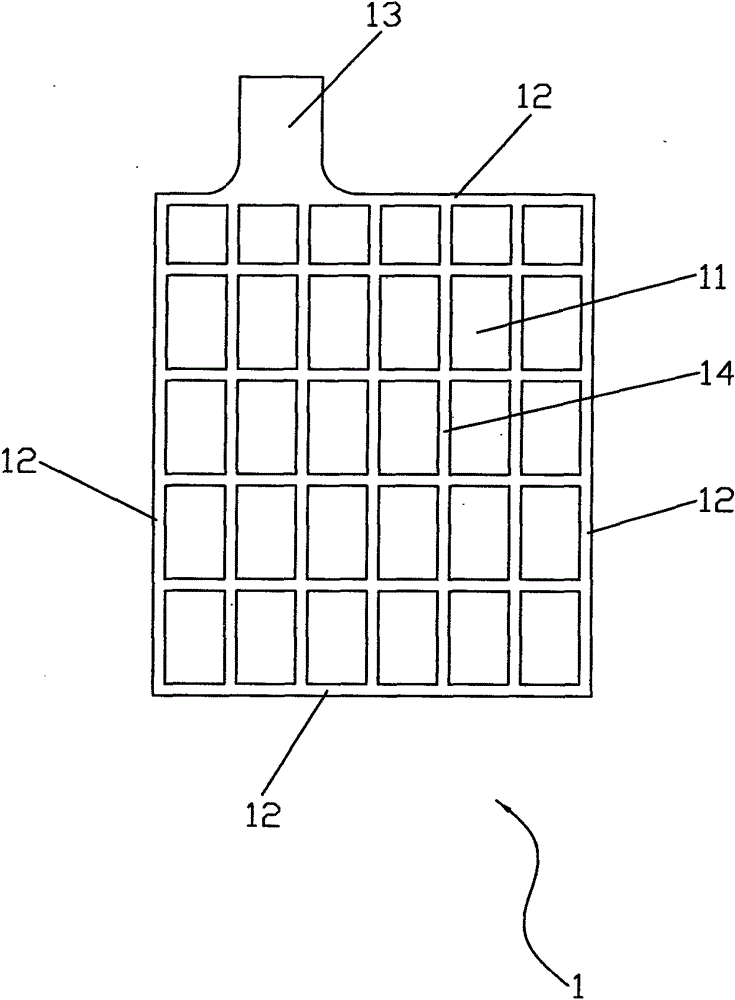

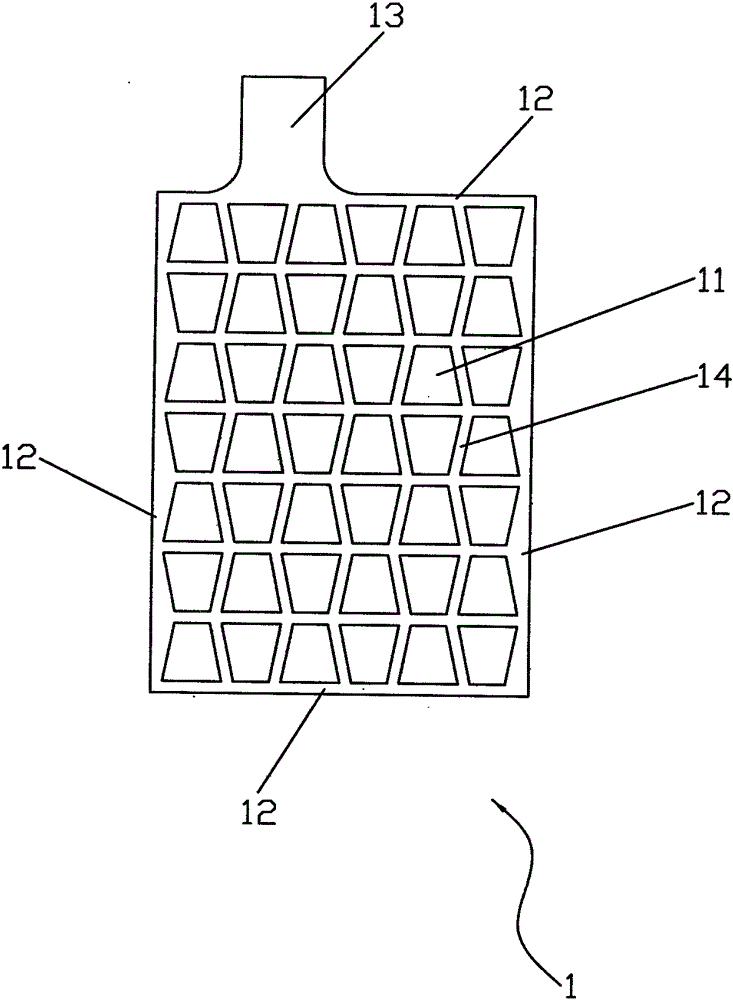

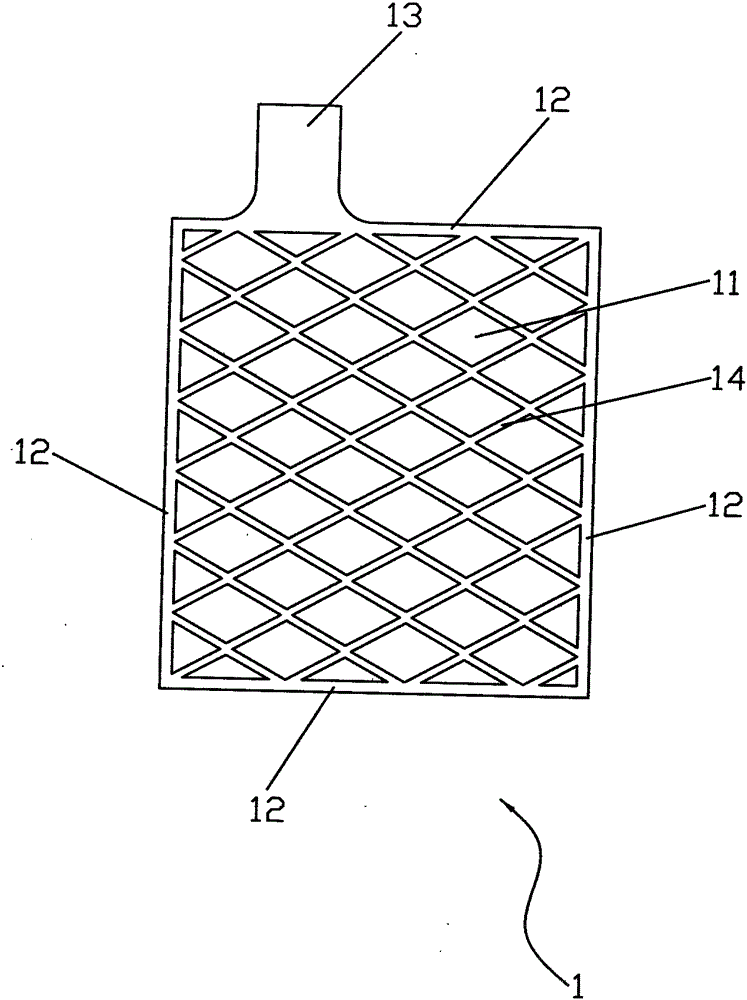

[0024] Such as Figure 1 ~ Figure 4 As shown, the lead-acid battery electrode grid 1 provided by the embodiment of the present invention includes a lead substrate (i.e. a rolled lead strip), on which a number of evenly distributed mesh holes 11 are punched, and a frame 12 is respectively arranged around the substrate. , one of the frames 12 is provided with an outwardly protruding tab 13 .

[0025] After the electrode grid 1 of the present invention is used on a lead-acid battery, the mesh 11 of the electrode grid 1 is filled with active electrolytic substances, and the current generated by the ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com