Preparation process of preserved wet noodles

A production process and wet noodle technology, applied in food preparation, application, food science, etc., can solve problems that affect product sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

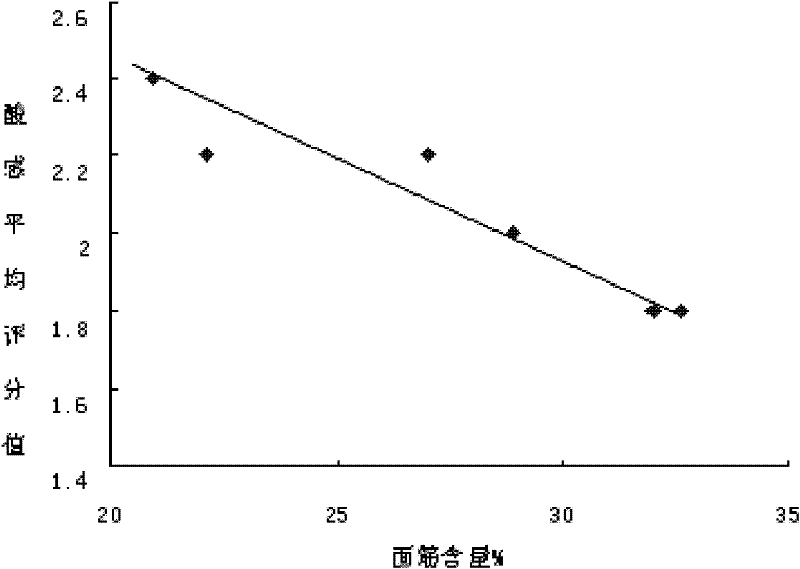

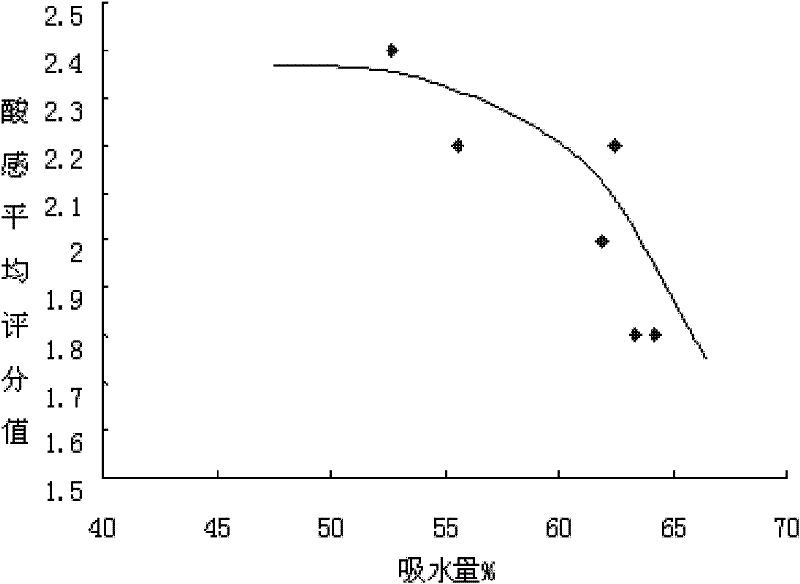

[0054] 1. Establish evaluation criteria for the sourness of fresh-keeping wet noodles

[0055] According to the sourness of the surface, the sourness is divided into 6 levels, and the sourness of each level is defined and described, and the scoring criteria shown in Table 2 are obtained:

[0056] Table 2 Definition and scoring standard of sour feeling of fresh-keeping wet noodle

[0057]

[0058] Control sample makes batching as shown in table 3:

[0059] Table 3 Recipe for fresh-keeping wet ramen

[0060]

[0061] (1) Flour, modified starch, gluten, sodium carboxymethyl cellulose, sodium carbonate, salt of wormwood, salt and water are mixed by the consumption shown in table 3;

[0062](2) Using a vacuum dough mixer to fully mix the above-mentioned powder and liquid into a dough, press the dough into a noodle strip, and leave the noodle strip to mature for 30 to 45 minutes;

[0063] (3) Use the noodle strip continuous calender to press the mature noodle strip to the r...

Embodiment 2

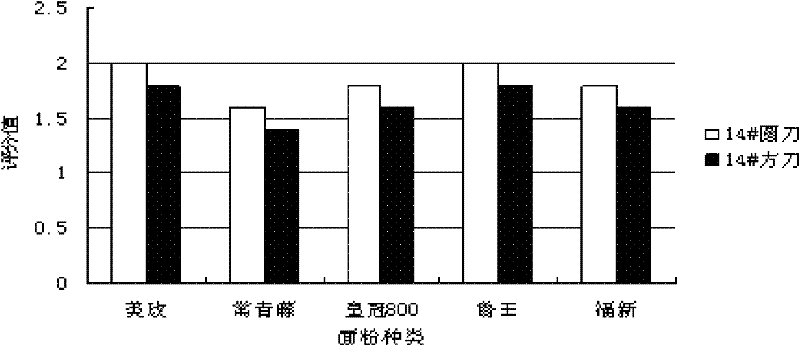

[0104] The inventor carries out sour feeling evaluation to the fresh-keeping wet noodle product made by following process, and concrete production process is:

[0105] (1) Mix 3000 grams of crown flour, 260 grams of modified starch, 20 grams of gluten, 11 grams of sodium carboxymethylcellulose, 13 grams of sodium carbonate, 60 grams of salt and 1250 grams of water;

[0106] (2) Use a vacuum dough mixer to fully mix the above-mentioned powder and liquid into dough, press the dough into dough strips, and leave the dough strips to mature for 40 minutes;

[0107] (3) Use a noodle belt continuous calender to press the matured noodle belt to the required thickness, and then use a #14 round knife to cut strips to make noodle bodies;

[0108] (4) The noodle is placed in boiling water and boiled for 1 minute;

[0109] (5) Rinse the boiled noodles with water below 20°C and with a hardness of below 8°C for 2 minutes, and then pickle in an aqueous solution containing 0.7wt% lactic acid a...

Embodiment 3

[0113] The inventor carries out sour feeling evaluation to the fresh-keeping wet noodle product made by following process, and concrete production process is:

[0114] (1) Mix 3000 grams of Fuxin No. 1 flour, 210 grams of modified starch, 22 grams of gluten powder, 14 grams of sodium carboxymethylcellulose, 15 grams of sodium carbonate, 60 grams of salt and 1280 grams of water;

[0115] (2) Use a vacuum dough mixer to fully mix the above-mentioned powder and liquid into dough, press the dough into dough strips, and leave the dough strips to mature for 40 minutes;

[0116] (3) Use a noodle belt continuous calender to press the matured noodle belt to the required thickness, and then use a #18 square knife to cut strips to make noodle bodies;

[0117] (4) The noodle is placed in boiling water and boiled for 3 minutes;

[0118] (5) Rinse the boiled noodles with water below 20°C and with a hardness of below 8°C for 2 minutes, and then dip in an aqueous solution containing 0.8wt% l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com