Filter membrane cleaning system for water treatment equipment

A technology of water treatment equipment and cleaning system, applied in the field of water treatment, can solve the problems such as long-term cleaning and maintenance scheme of filter membrane, stable and continuous rotation of difficult-to-maintain rotating plate, affecting the efficiency and effect of decontamination, and achieve relatively smooth and stable rotation. Stable, maintain work performance, smooth rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

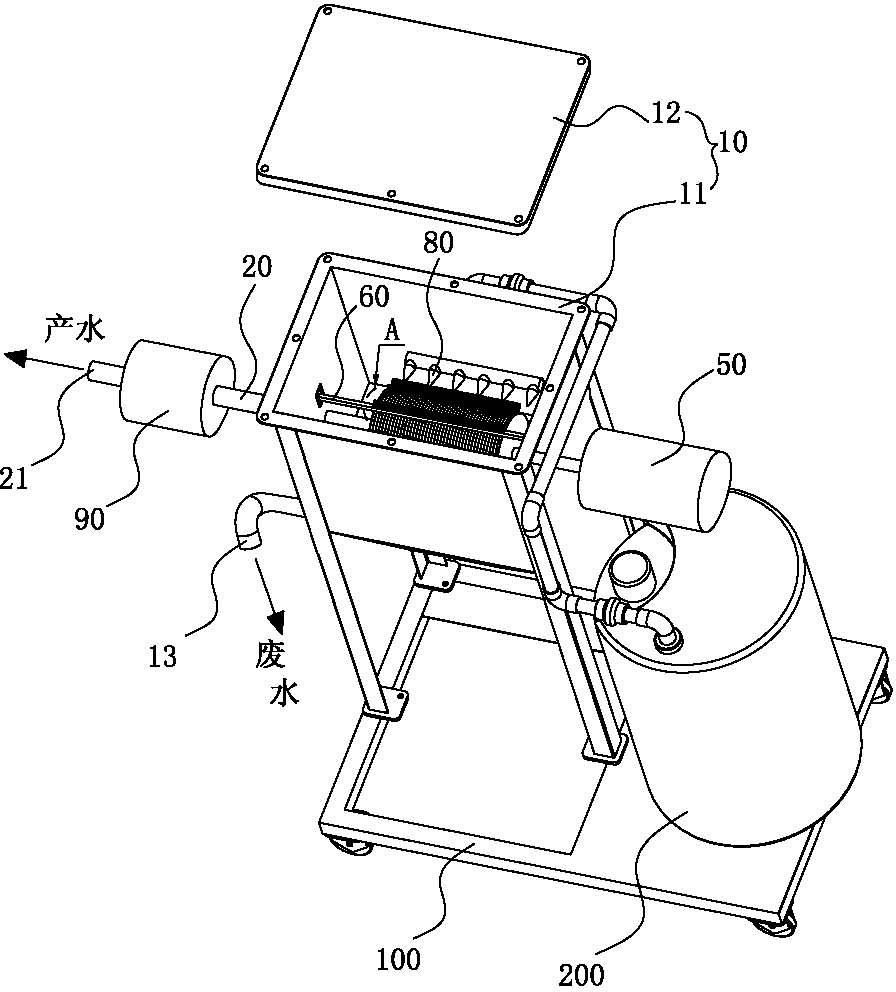

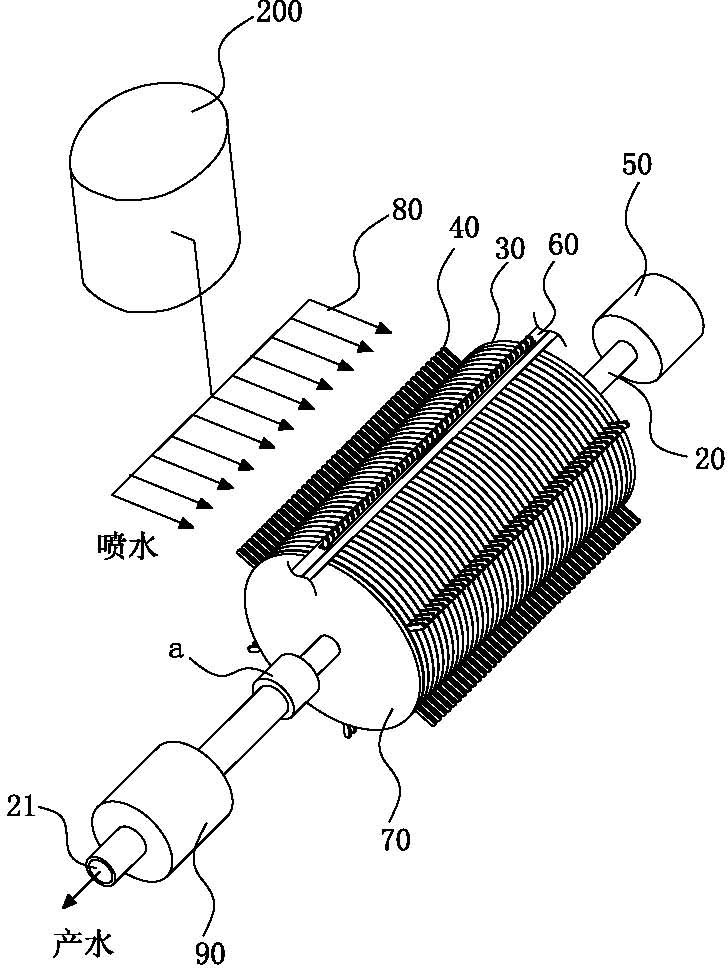

[0043] See Figure 1 to Figure 6 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a sealed container 10, which is installed on the base 100, in this embodiment, as figure 1 As shown, the sealed container 10 is a box structure, including a main body 11 and a cover plate 12 detachably locked on the main body 11; the sealed container 10 is provided with a waste water discharge port 13, and the sealed container A water production pipe 20 is provided through the inside of 10, and the water production pipe 20 is arranged along the horizontal direction, and a water production outlet 21 is provided at one end thereof.

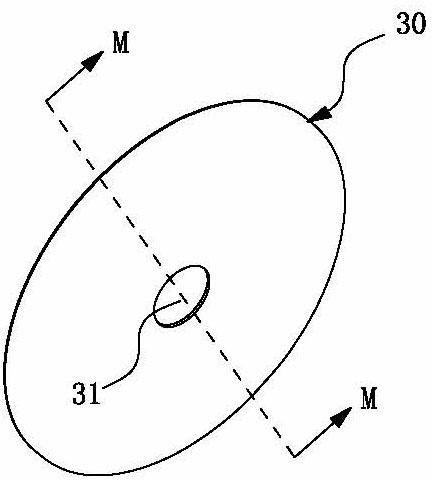

[0044] The structural feature of the present invention is that the outer peripheral surface of the aforementioned water production pipe 20 is provided with a plurality of filter membranes 30 along the axial spacing, and the filter membranes are fixed relative to the water production pipe, (see Image 6 As shown)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com