Manufacturing method of wedge-shaped lens

A manufacturing method and wedge mirror technology, which is applied in the manufacture of wedge mirrors with second-level precision, large angle, and small size, can solve the problems of low processing efficiency and yield rate, complex types of wedge mirrors, and small processing volume, etc., to achieve production The effect of shortened cycle, novel process method and good size consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

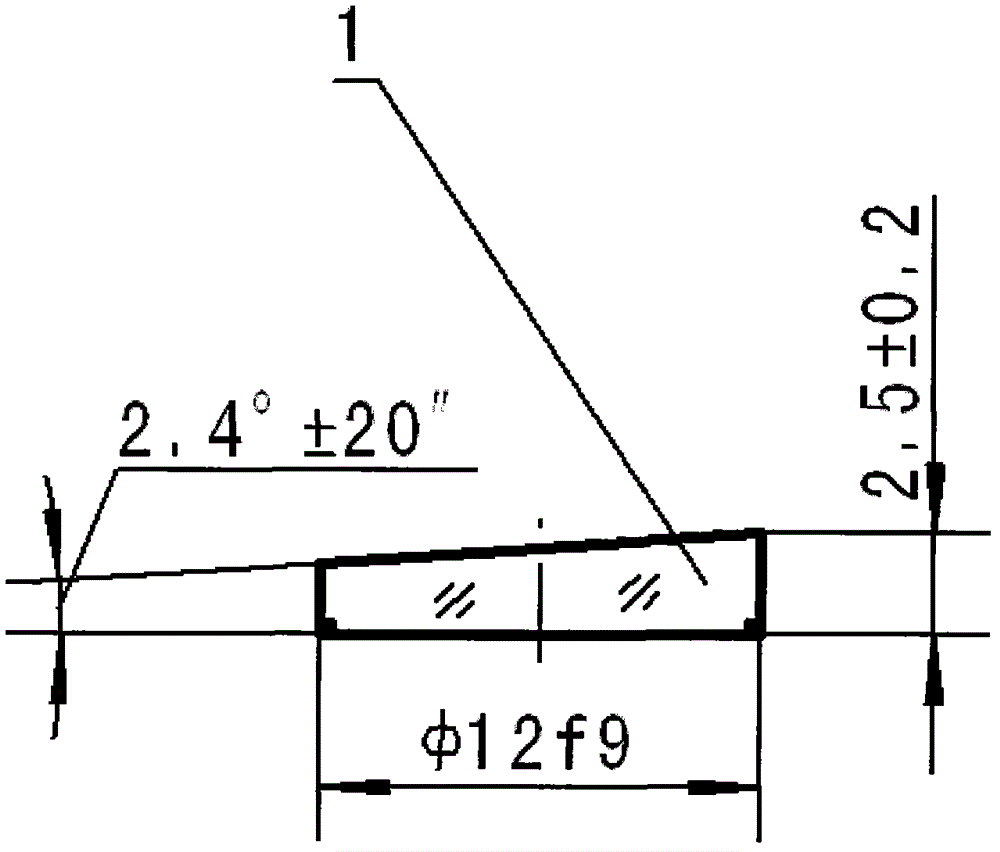

[0029] The present invention is aimed at figure 1 The shown manufacturing method of the wedge mirror 1 includes the following processing and inspection steps.

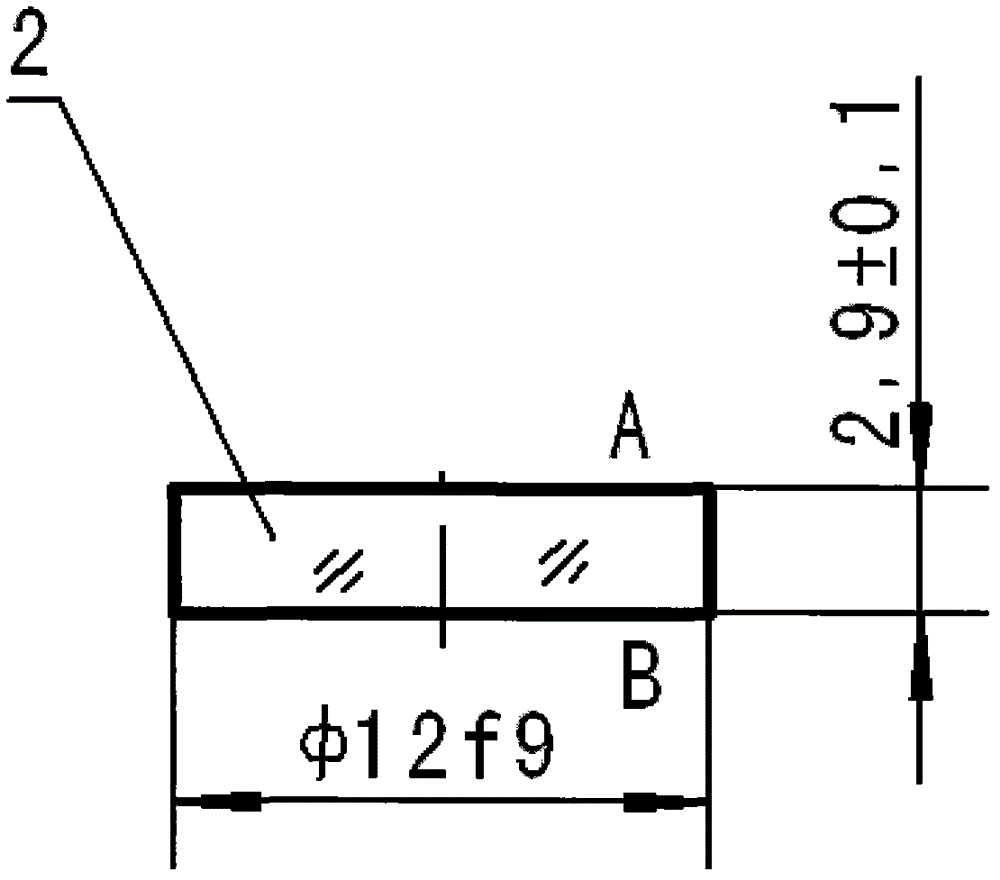

[0030] The first step adopts the optical parts processing technology to roughly grind and form the wedge-shaped mirror blank 2 (see figure 2 ), the forming indicators are: diameter Φ12f9mm; thickness 2.9mm±0.1mm; parallel difference ≤0.02mm; production quantity: 16 pieces. The first light-passing surface A of the wedge-shaped mirror blank 2 is finely ground and polished by optical processing technology, and the processing index requirements are: aperture N≤1, local aperture ΔN≤0.3, and surface defect B≤IV.

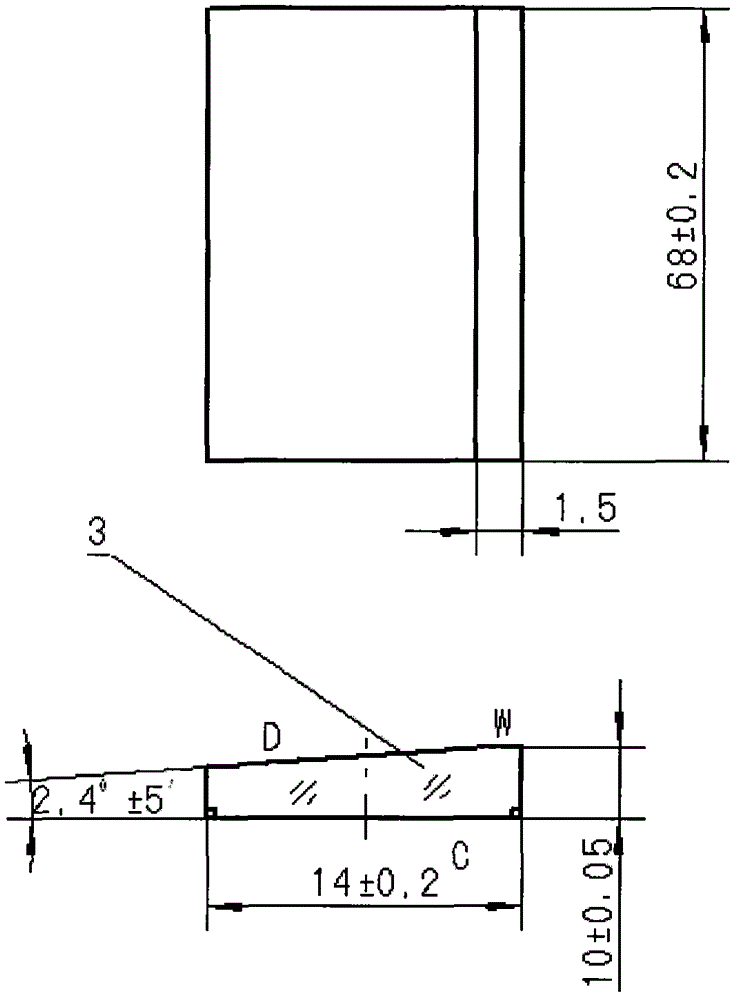

[0031] The second step is to adopt the optical parts processing technology to process the roughly ground wedge-shaped glass fixture 3 (see image 3 ), wherein: a ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com