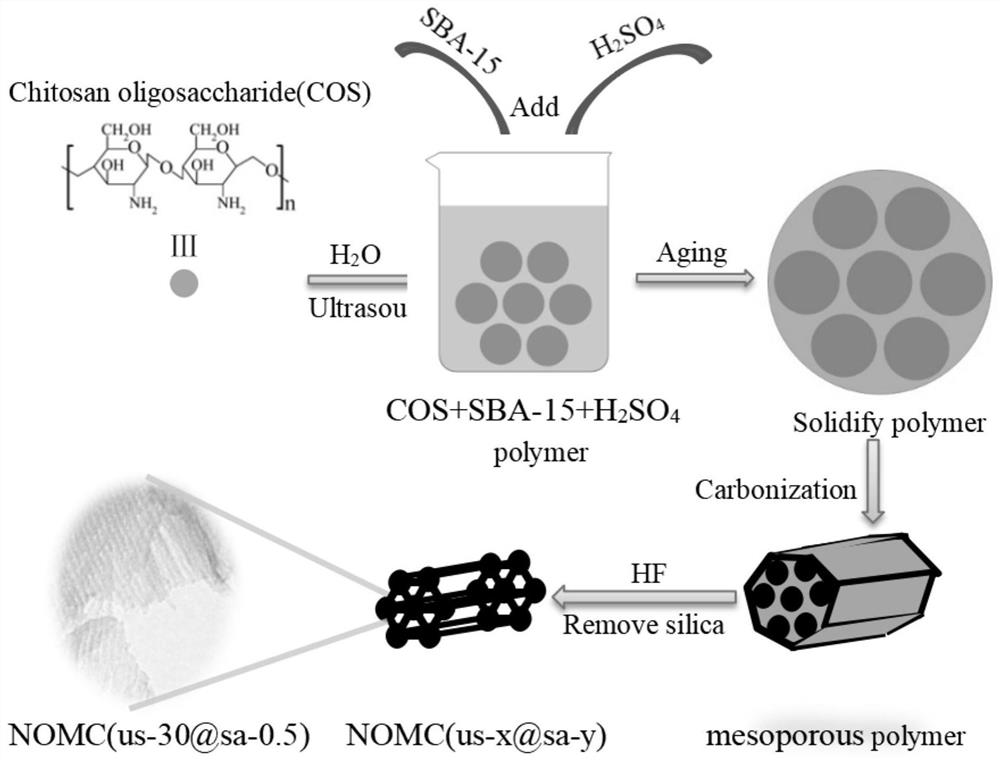

Preparation method of chitosan oligosaccharide-based in-situ N-doped ordered mesoporous carbon with uniform and adjustable pore diameter

A technology of mesoporous carbon and chitosan oligosaccharide, which is applied in the field of preparation of ordered mesoporous carbon, can solve the problems of pore structure damage, pore size control hindrance, complicated steps, etc., and achieve uniform and controllable pore size, novel process method and low production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

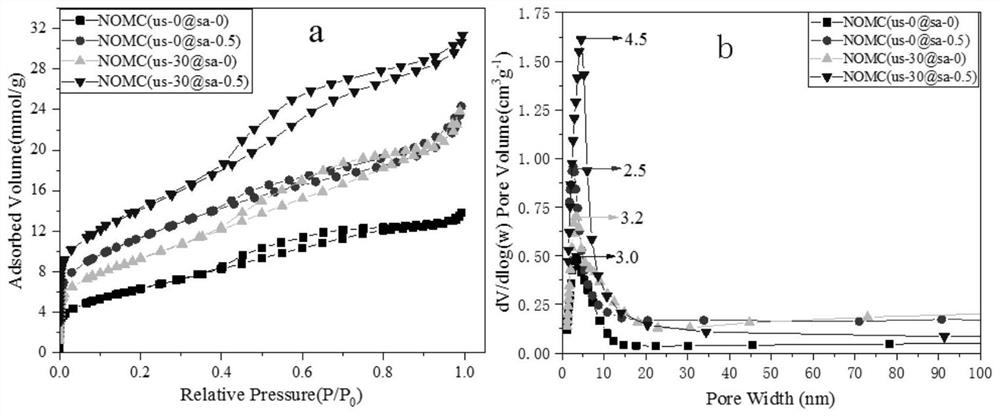

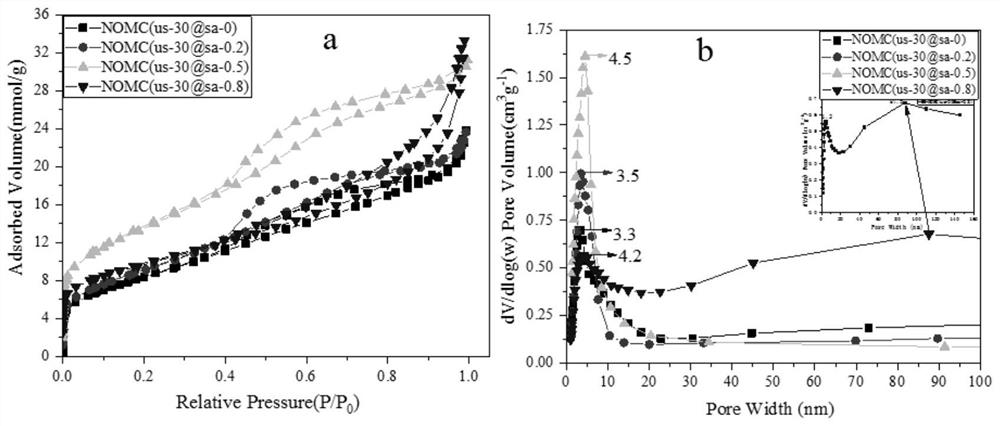

[0061] Embodiment 1: A kind of preparation method of uniform adjustable chitosan oligosaccharide base in-situ N-doped ordered mesoporous carbon with pore size, specifically comprises the following steps:

[0062] 1) Preparation of SBA-15 ordered mesoporous silica template: Dissolve P123 in HCl solution, and stir evenly in a water bath, slowly add tetraethyl orthosilicate and continue stirring at this temperature, then Pour the mixture into a hydrothermal tank for hydrothermal reaction, cool it, take it out, wash it, then dry it, and then put the product into a tube furnace to heat up and calcinate to obtain a surfactant-free SBA-15 ordered mesoporous silica template ; wherein the concentration of the HCl solution is 5.5wt%; the temperature of the water bath is 40°C; the mass ratio of P123 to ethyl orthosilicate is 1:2.1, and the stirring time after adding ethyl orthosilicate is 20h; The temperature of the hydrothermal reaction is 100°C, and the time is 12h; the final temperatu...

Embodiment 2

[0067] Embodiment 2: the preparation method of N-doped ordered mesoporous carbon of a kind of aperture uniform adjustable chitosan oligosaccharide base in situ, specifically comprises the following steps:

[0068] 1) Preparation of SBA-15 ordered mesoporous silica template: Dissolve P123 in HCl solution, and stir evenly in a water bath, slowly add tetraethyl orthosilicate and continue stirring at this temperature, then Pour the mixture into a hydrothermal tank for hydrothermal reaction, cool it, take it out, wash it, then dry it, and then put the product into a tube furnace to heat up and calcinate to obtain a surfactant-free SBA-15 ordered mesoporous silica template ; wherein the concentration of the HCl solution is 5wt%%; the temperature of the water bath is 30°C; the mass ratio of P123 to ethyl orthosilicate is 1:2, and the stirring time after adding ethyl orthosilicate is 15h; The temperature of the hydrothermal reaction is 90° C., and the time is 15 hours; the final tempe...

Embodiment 3

[0073] Embodiment 3: A kind of preparation method of uniform adjustable chitosan oligosaccharide base in-situ N-doped ordered mesoporous carbon with pore size, specifically comprises the following steps:

[0074] 1) Preparation of SBA-15 ordered mesoporous silica template: Dissolve P123 in HCl solution, and stir evenly in a water bath, slowly add tetraethyl orthosilicate and continue stirring at this temperature, then Pour the mixture into a hydrothermal tank for hydrothermal reaction, cool it, take it out, wash it, then dry it, and then put the product into a tube furnace to heat up and calcinate to obtain a surfactant-free SBA-15 ordered mesoporous silica template ; wherein the concentration of the HCl solution is 6wt%; the temperature of the water bath is 40°C; the mass ratio of P123 to ethyl orthosilicate is 1:3, and the stirring time after adding ethyl orthosilicate is 25h; The temperature of the hydrothermal reaction is 110°C, and the time is 10h; the final temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com