Compound of aluminum or aluminum alloy and plastics and manufacturing method thereof

A production method and technology of aluminum alloy, applied in chemical instruments and methods, thin material processing, metal layered products, etc., can solve the problems of aging and fracture of adhesives, low production efficiency, difficulty in automation, etc., to shorten the process and enhance the bonding force. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

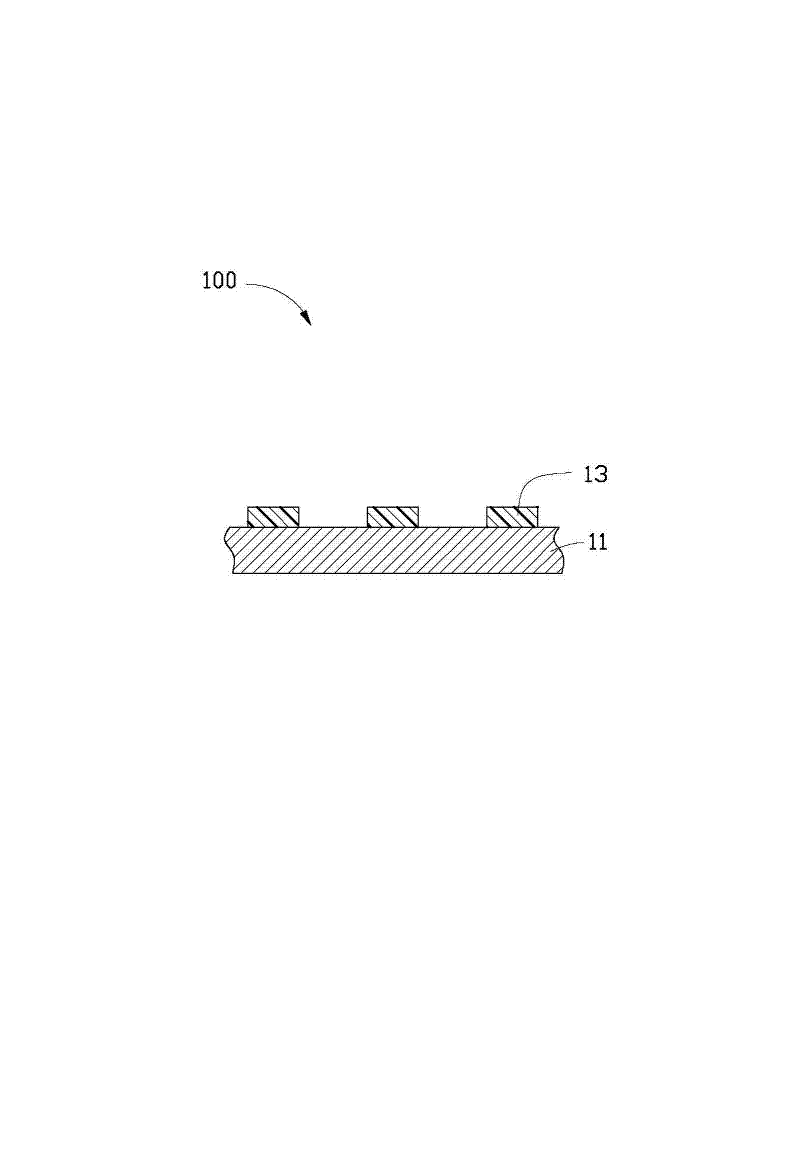

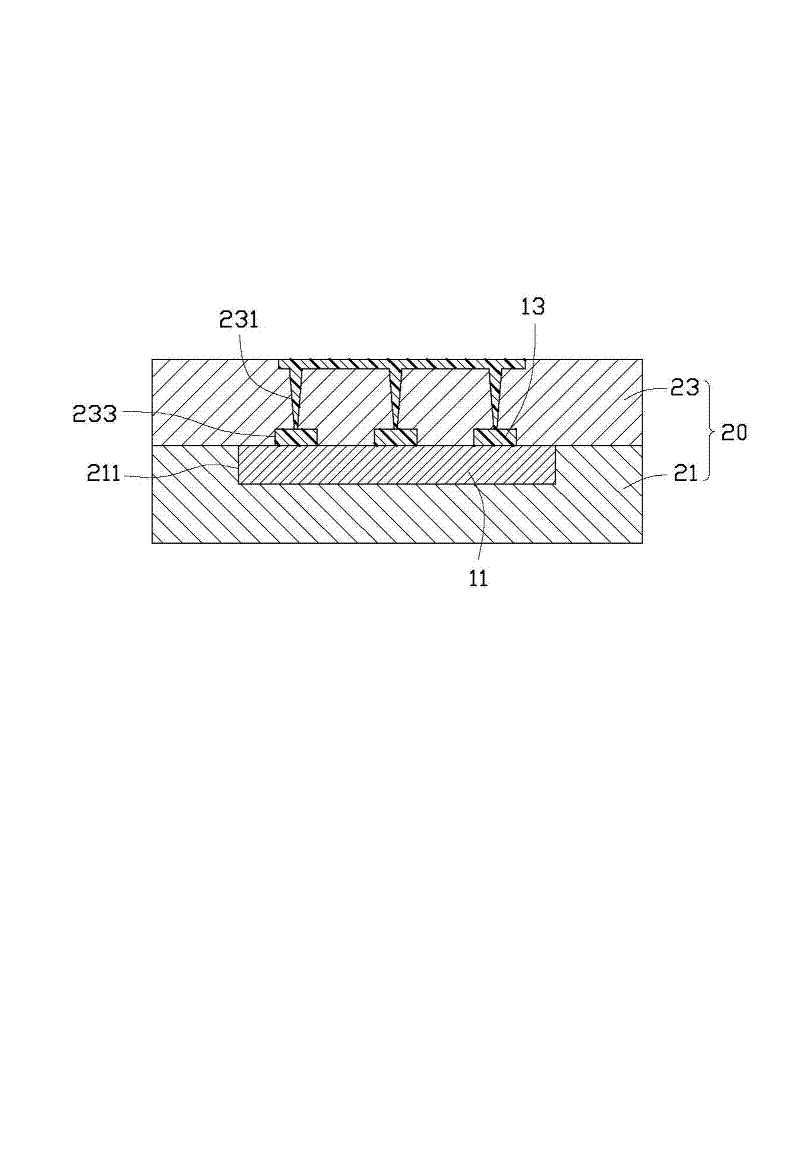

[0019] see figure 1 , A composite body 100 of aluminum or aluminum alloy and plastic in a preferred embodiment of the present invention includes an aluminum or aluminum alloy substrate 11 and several plastic parts 13 formed on the surface of the aluminum or aluminum alloy substrate 11 .

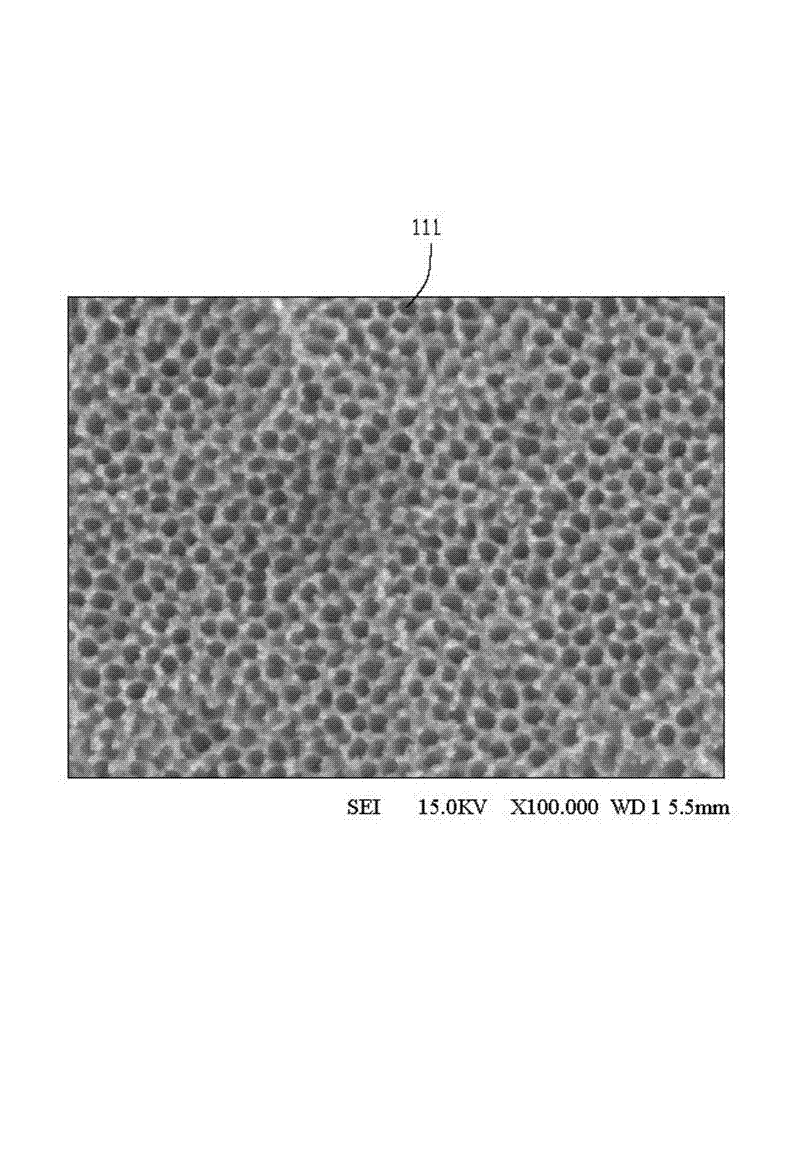

[0020] see figure 2 A plurality of nanopores 111 are formed on the surface of the aluminum or aluminum alloy substrate 11, and the average diameter of the plurality of nanopores 111 is 20-60 nm. From figure 2 It can be seen that the number of nanopores 111 are evenly distributed on the surface of the aluminum or aluminum alloy substrate 11 . The existence of the several nanoholes 111 can make part of the plastic injection-molded the plastic parts 13 embedded in the several nanoholes 111, thereby enhancing the bonding force between the several plastic parts 13 and the aluminum or aluminum alloy substrate 11. The surface roughness Ra of the aluminum or aluminum alloy substrate 11 is 0.1-1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com