Circulation cooling device for chute of soda recovery furnace

A circulating cooling and recovery furnace technology, applied in furnace cooling, lye regeneration, furnace, etc., can solve problems such as complex equipment composition, reduced heat transfer effect, complex equipment installation, etc., to achieve timely warning of leakage events and improve scaling , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and examples.

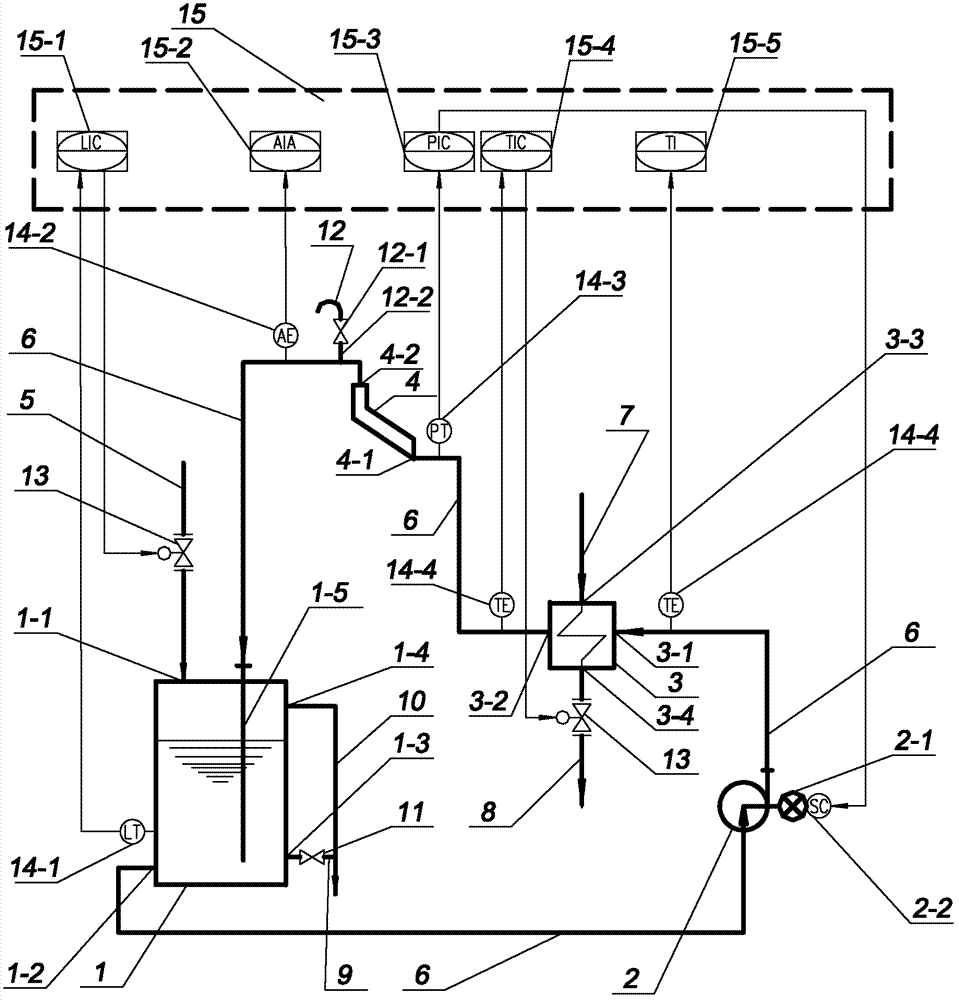

[0052] Such as figure 1 As shown, a circulating cooling device for an alkali recovery furnace chute includes a cooling water tank 1, a frequency conversion water pump 2, a heat exchanger 3 and a PLC control device 15.

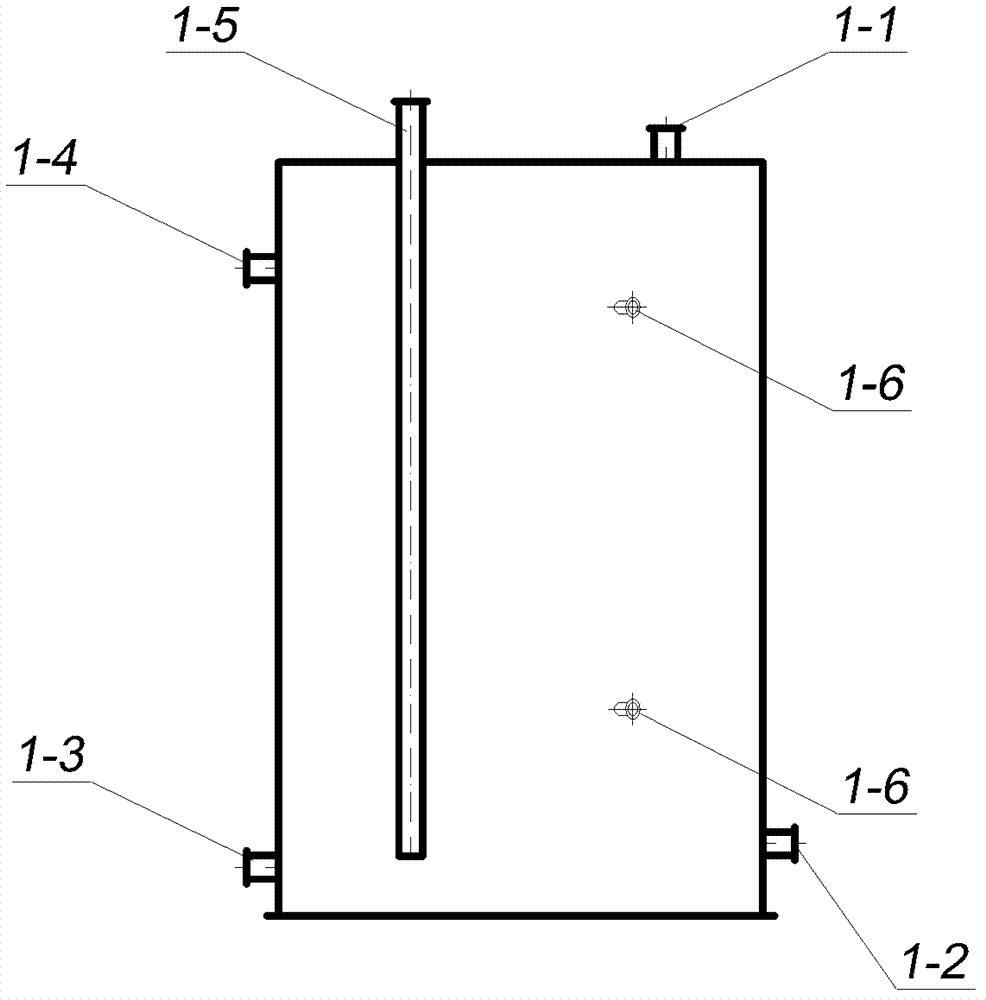

[0053] Cooling water tank 1 is provided with desalted water inlet 1-1, desalted water outlet 1-2, sewage outlet 1-3, overflow outlet 1-4, water seal pipe 1-5 and liquid level gauge interface 1-6, water seal Pipe 1-5 is inserted below the liquid level of cooling water tank 1, liquid level gauge interface 1-6 is connected with liquid level transmitter 14-1, and sewage outlet 1-3 is connected with sewage pipe 9 for regular replacement of water in cooling water tank 1. For desalinated water, the drain pipe 9 is provided with a drain valve 11, and the overflow port 1-4 is connected to the overflow pipe 10 for discharging excessive circulating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com