Heating floor formed by connecting metal heat-transfer element and heating element at low thermal resistance

A heating element and low thermal resistance technology, which is applied in the field of heating floors and heat pipes, can solve the problems such as the difficulty of ensuring the surface contact heat exchange state, the small heat transfer area between the floor heating pipes and the floor, the use of keels and floor heating pipes, etc., so as to save wood. , the effect of preventing termite erosion and optimizing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

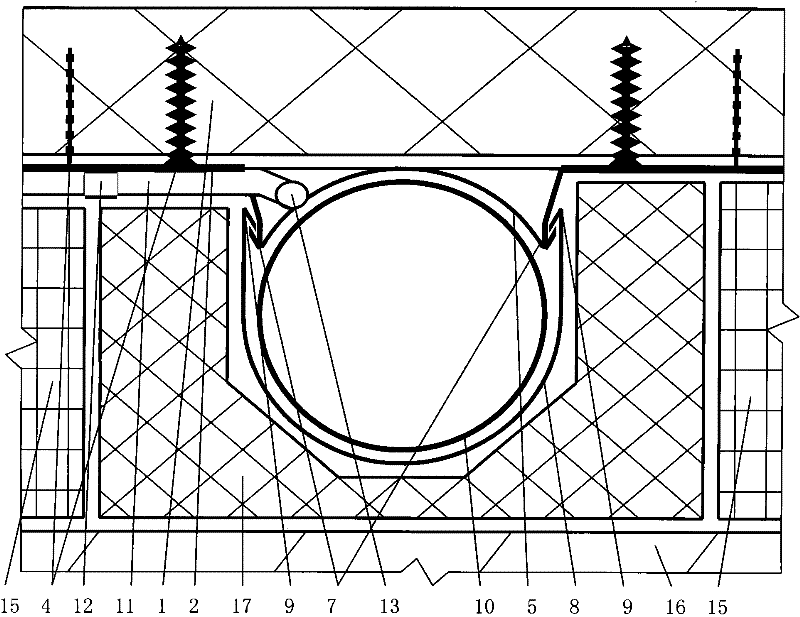

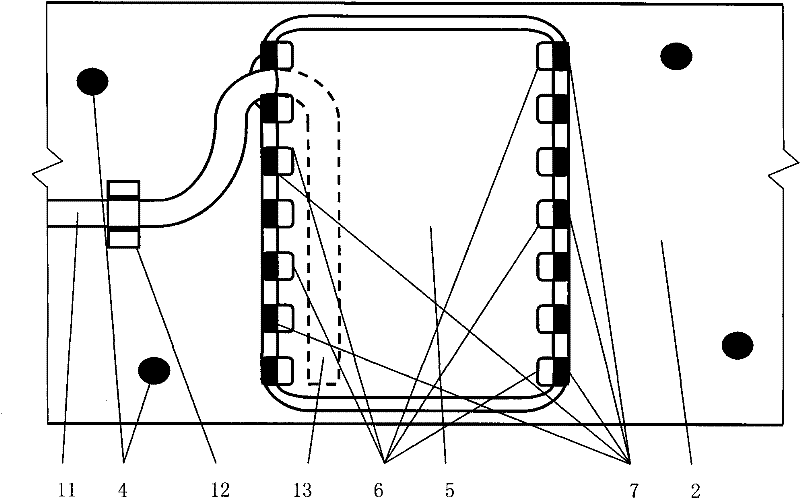

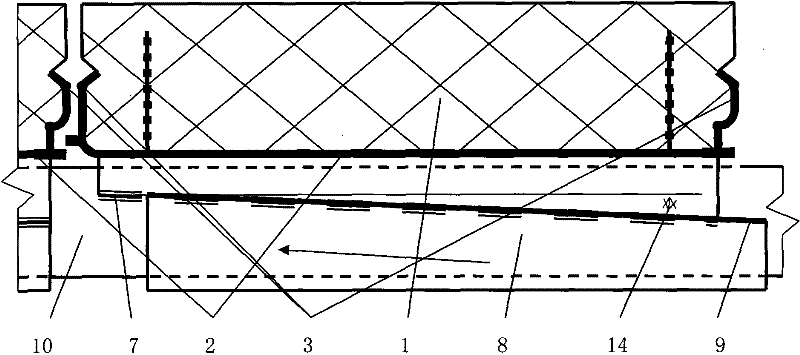

[0034] Figure 1~3 A first embodiment of the present invention is collectively given. Figure 1~3 Among them, the metal heat conduction plate 2 arranged on the lower surface of the floor panel 1 wraps the floor panel 1 from both sides with the wrapping 3 to realize a fixed low thermal resistance connection with the floor panel 1 . The metal heat conducting plate 2 and the ground plate 1 are also connected by silica gel bonding and screws 4 with low thermal resistance. The metal heat conducting plate 2 presses down a groove 5 , and the groove 5 contains two rows of fixed flanges 7 formed by flange holes 6 . Fixed flange 7 utilizes the material that flange hole 6 turns over on groove 5 to make, and a plurality of fixed flanges 7 are arranged in a row. The fixed flange 7 hooks up the two connecting flanges 9 of the U-shaped cover plate 8 . The trough 5 on the metal heat conducting plate 2 and the U-shaped cover plate 8 wrap and connect the hot water pipe 10 together with low t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com