Air-cooled heat pump unit

An air-cooled heat pump and fan technology, which can be used in household heating, heating methods, mechanical equipment, etc., can solve the problems of poor defrosting effect, low heat exchange effect, and restrictions on the application of all-aluminum microchannel heat exchangers, and achieve increased The effect of large heat transfer area and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Taking the straight all-aluminum microchannel heat exchanger as an example, the specific implementation method is as follows:

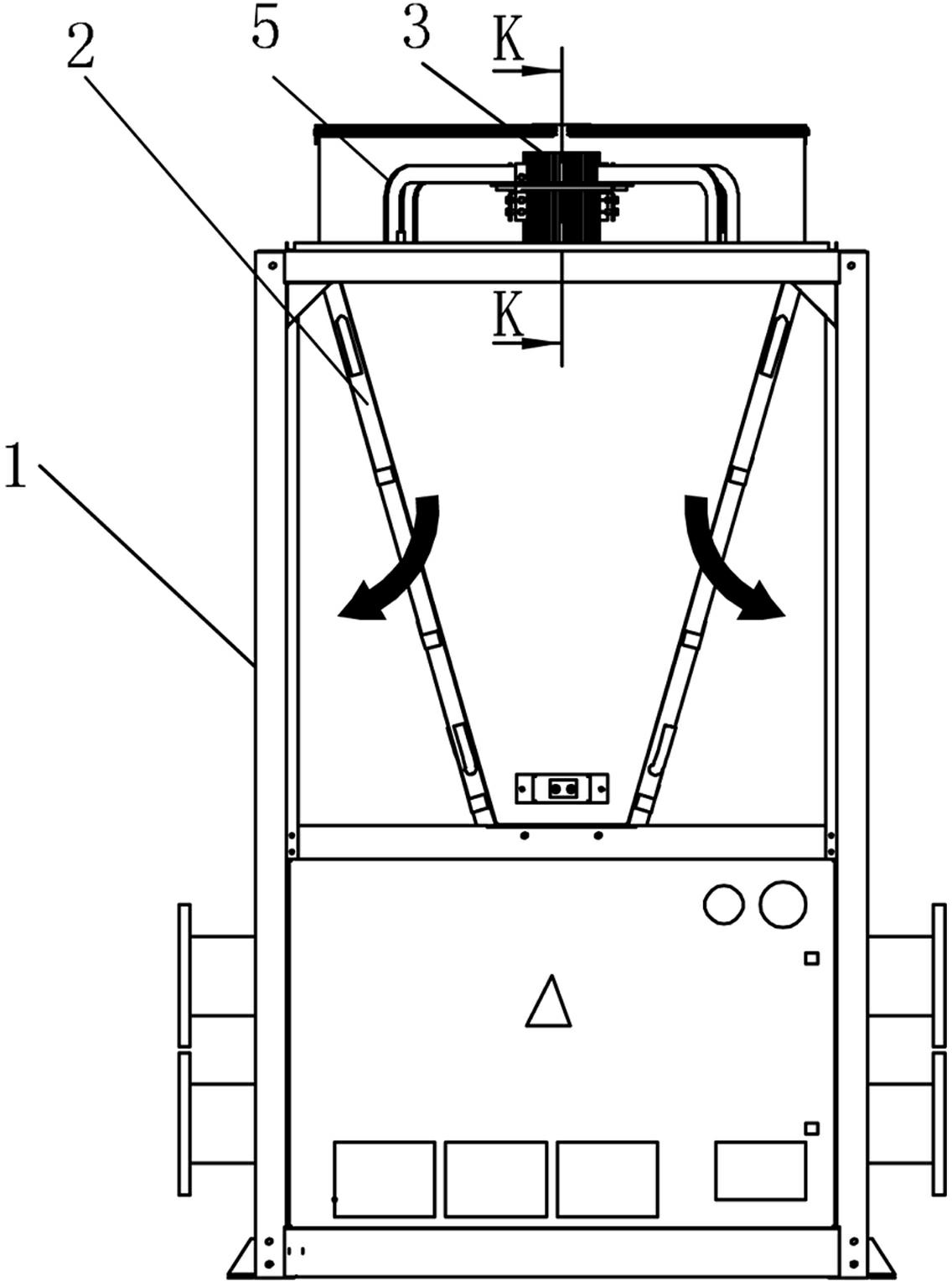

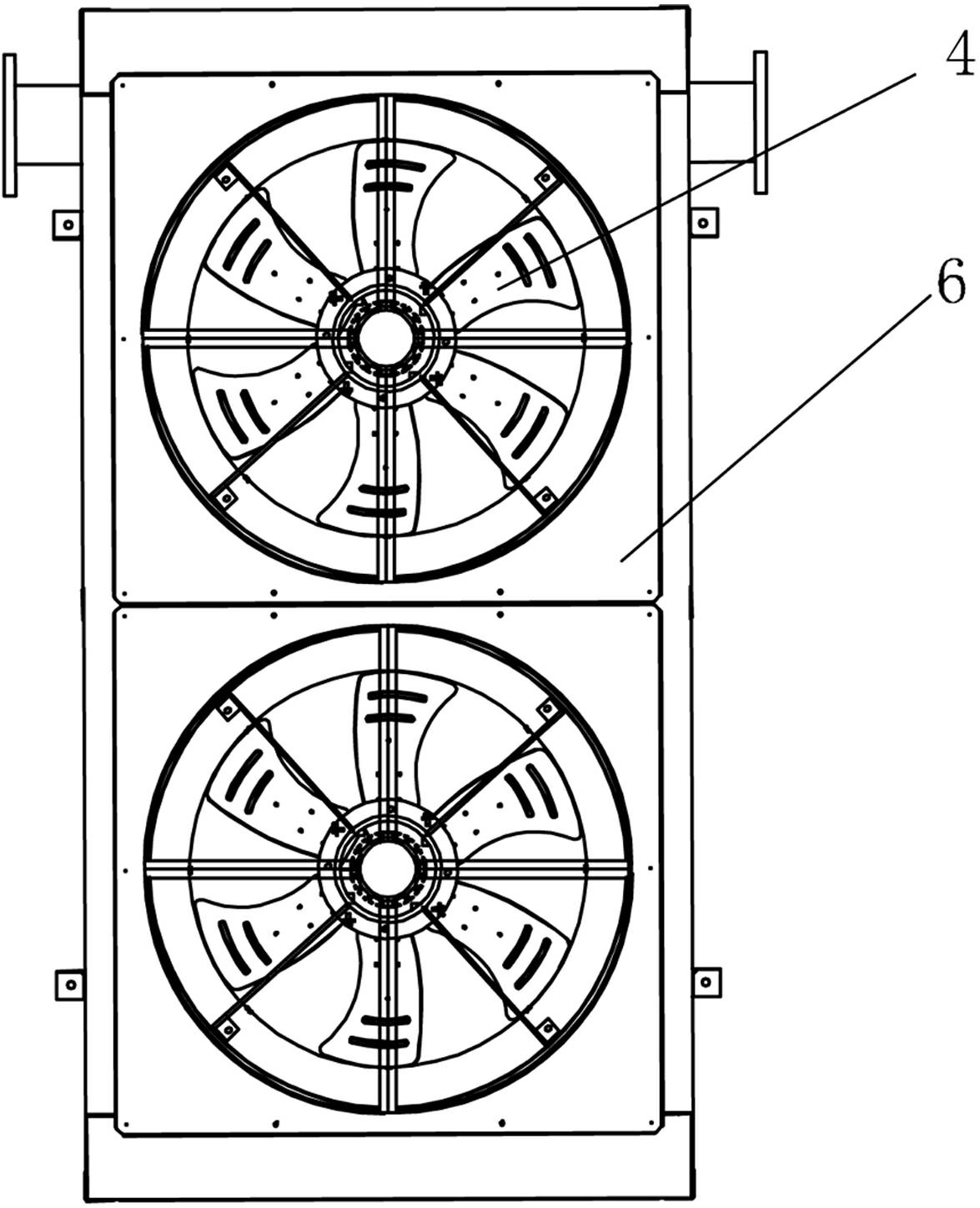

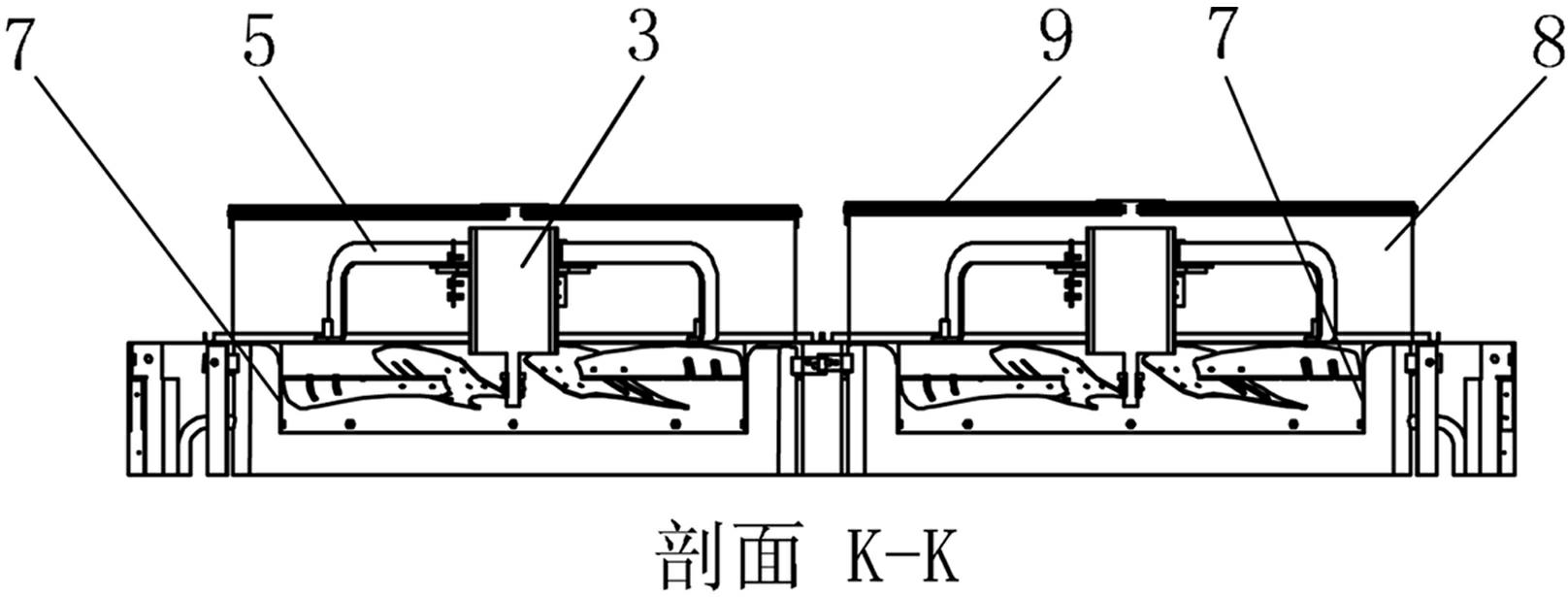

[0020] Such as Figure 1-3 As shown, a fan port plate 6 is set above the body 1, a fan motor 3, a fan blade 4 and a fan support 5 are arranged on the fan port plate 6, and a shroud 7 is arranged below the fan port plate 6, and the direction of the shroud 7 is downward. A flow equalizing cover 8 is arranged outside the motor, and the direction of the flow equalizing cover 8 is upward, and a filter screen 9 is arranged above the flow equalizing cover 8, and the filter screen can be easily disassembled to form a ventilation system under the blower fan.

[0021] Such as Figure 4-7 As shown: an all-aluminum micro-channel heat exchanger 2 is set on the upper part of the body 1; the cross-section of the micro-channel 2-7 in the all-aluminum micro-channel heat exchanger 2 is a diamond-shaped structure for parallel flow inside the all-aluminum micro-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com