Device and method for measuring return flow of L-shaped communicating pipe drilling liquid

The technology of a flow measuring device and a connecting pipe is applied in the field of L-shaped connecting pipe drilling fluid return flow measuring device, which can solve problems such as inability to accurately measure, and achieve the effects of improving detection accuracy, avoiding measurement difficulties, and advancing early warning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

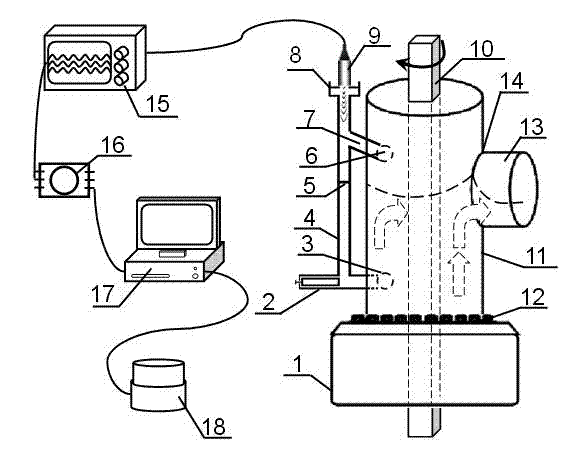

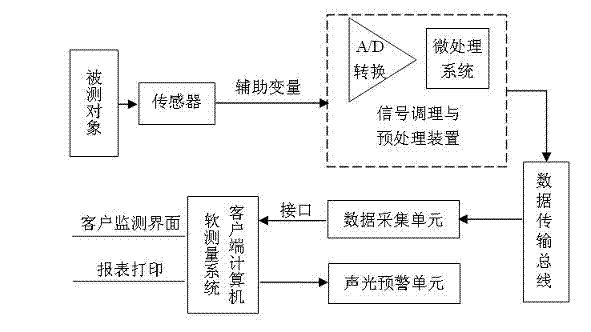

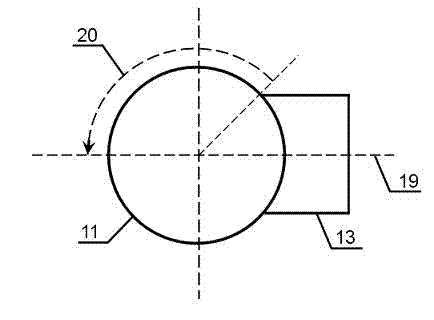

[0039] Below in conjunction with accompanying drawing, the present invention will be further described:

[0040] like figure 1 As shown, the L-shaped connecting pipe drilling fluid return flow measuring device of the present invention consists of an optical liquid level sensor 9, an L-shaped connecting pipe 4, a trumpet pipe 11, an L-shaped connecting pipe bracket 8, a signal conditioning and preprocessing device 15, and a data The acquisition unit 16, the client computer 17, and the sound and light alarm device are composed. At present, when the drilling fluid is openly circulated at the oil drilling site, the return flow measurement is mostly installed at the wellhead with the horn tube 11 and the annular blowout preventer 1, and the horn tube 11 and the annular blowout preventer 1 are below the drill floor plane, the kelly 10 passes through the horn tube 11, and the horn tube 11 is connected to a rectangular groove, and the increase or decrease of the total amount of liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com