Industrial film digital once imaging system

An imaging system and film technology, which is applied in the direction of optical testing defects/defects, can solve the problems of staff's visual damage, low definition, long scanning time, etc., to avoid external light interference, expand the blackness range, and improve imaging effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

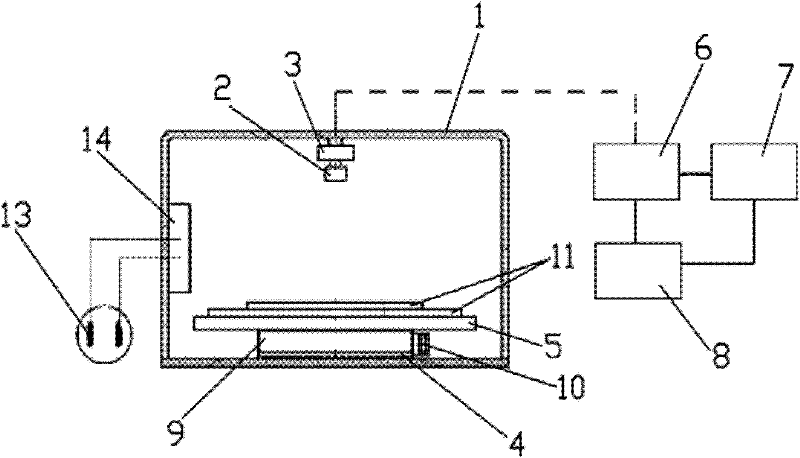

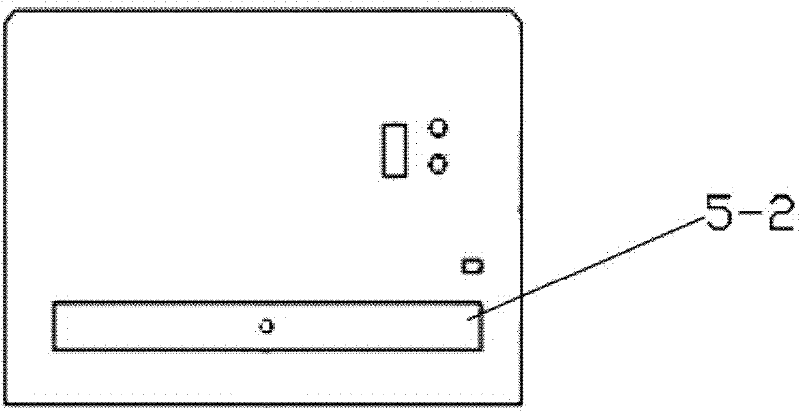

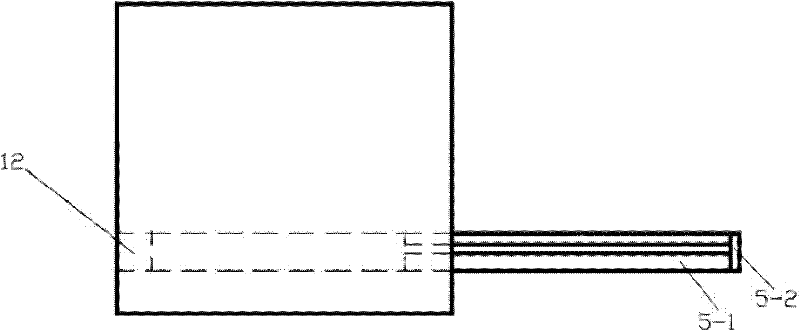

[0027] like Figure 1~3 As shown, the industrial film digital primary imaging system of the present embodiment includes: a housing 1, an optical lens 2, an image acquisition module 3, a cold light source 4 and a film delivery module 5 for sending an industrial film, and the optical lens 2 is set Above the inner side of the housing 1, the film feeding module 5 is arranged on the side of the housing 1 opposite to the optical lens 2, and the cold light source 4 is arranged below the inner side of the housing 1 and in the film feeding module 5 Directly below, the image acquisition module 3 is connected to the optical lens 2 for two-dimensional image acquisition, and converts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com