Low-temperature oxidation experimental method and device of crude oil extracted by injecting air into light oil reservoir

A light oil reservoir and experimental device technology, applied in the direction of analysis materials, instruments, etc., can solve the problems of low permeability reservoir pore structure damage, prone to explosion, lack of multi-channel acquisition system for pressure, temperature and volume data, etc. Achieve the effect of improving the heating uniformity of the sample and ensuring the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

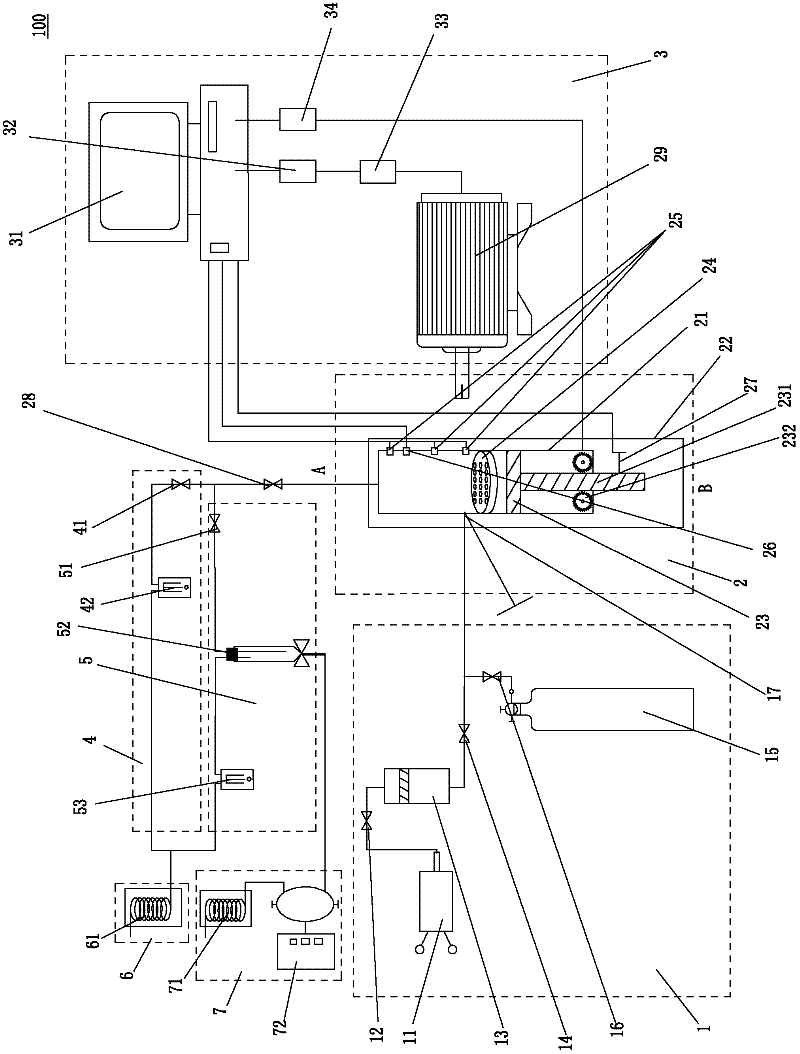

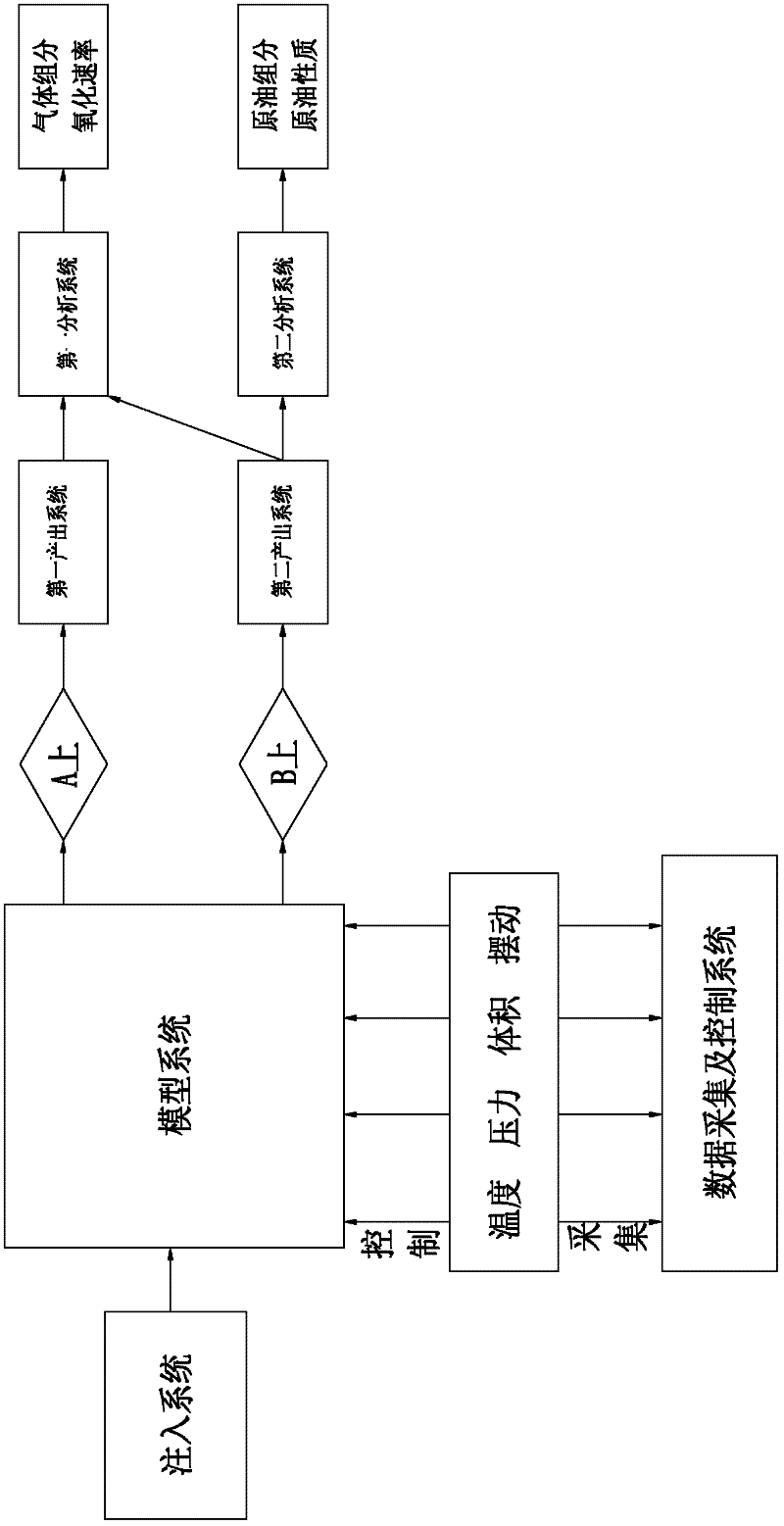

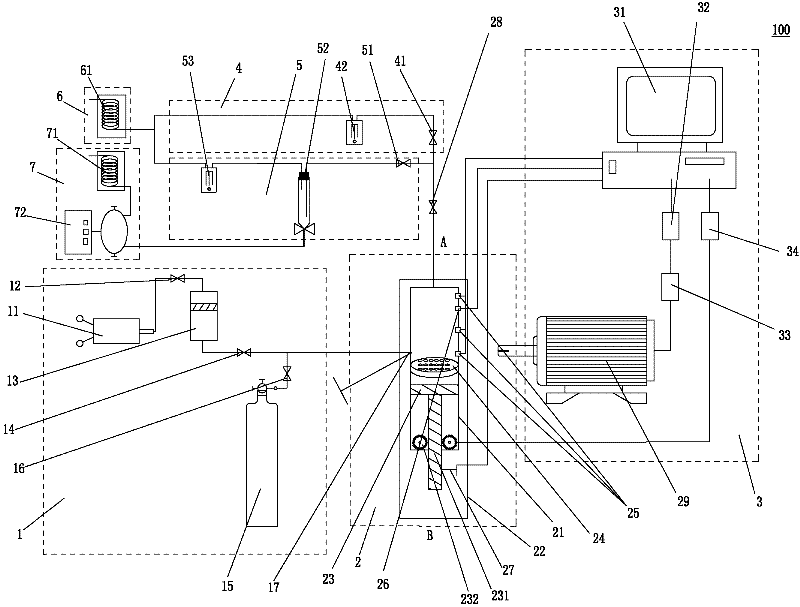

[0024] Such as figure 1 , figure 2 As shown, the present invention proposes an experimental device 100 for low-temperature oxidation of crude oil by air injection in light oil reservoirs. The experimental device 100 consists of an injection system 1, a model system 2, a data acquisition and control system 3, a first output system 4, The second output system 5, the first analysis system 6 and the second analysis system 7 are composed; the model system 2 can swing up and down around its last rotation center, and one side of the model system 2 is conductively connected to the injection system 1. The upper end of the model system 2 is connected to the first production system 4 for collecting free gas and the second production syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com