High-temperature superconductive magnetic suspension linear propulsion system with composite ontrack magnetizing function

A high-temperature superconducting and propulsion system technology, which is applied in the propulsion system, holding devices using magnetic attraction or thrust, electrical components, etc., can solve the problem of no high-efficiency magnetic levitation propulsion system, etc., and achieve advanced convenient efficiency and good system stability. , the overall performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

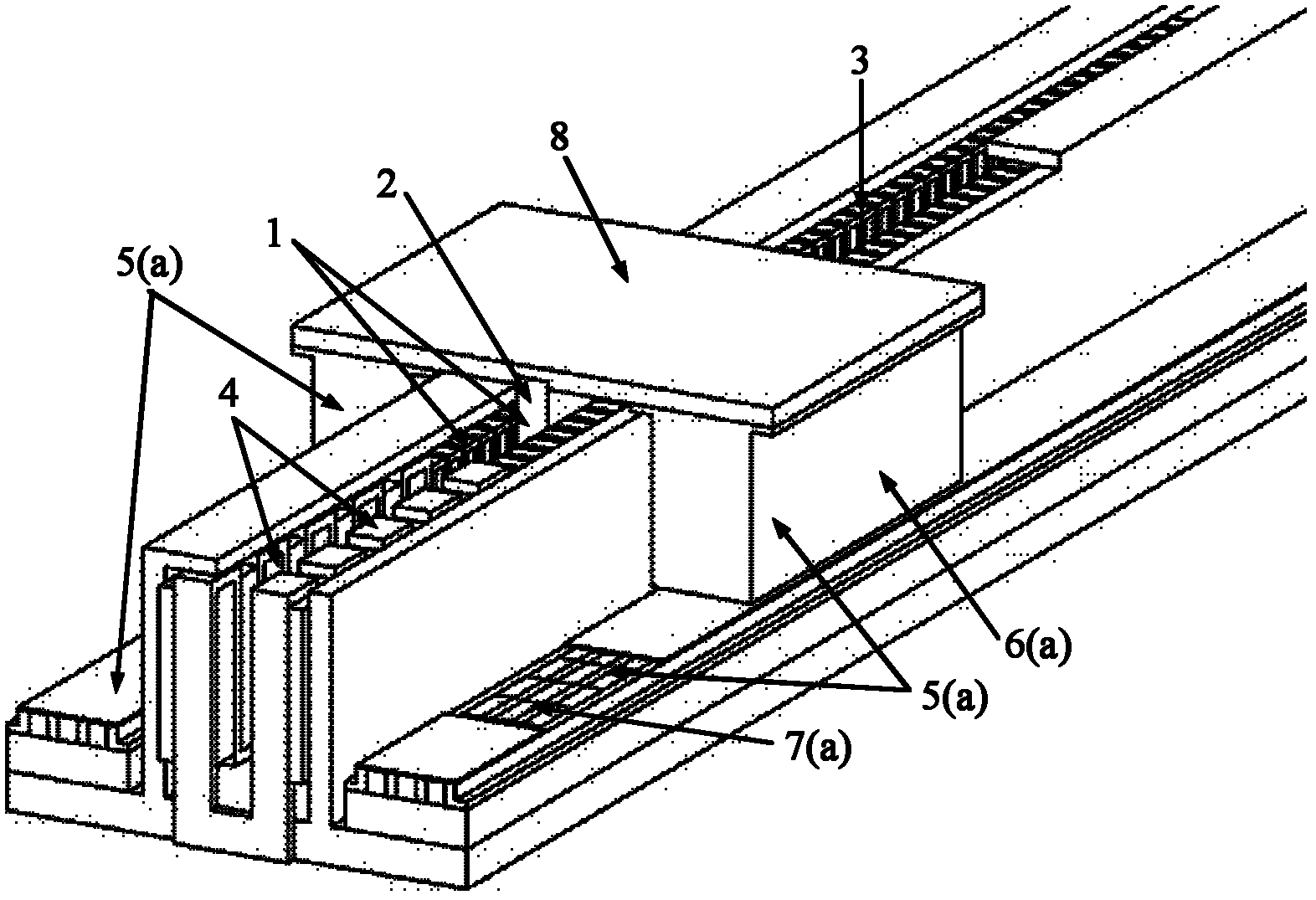

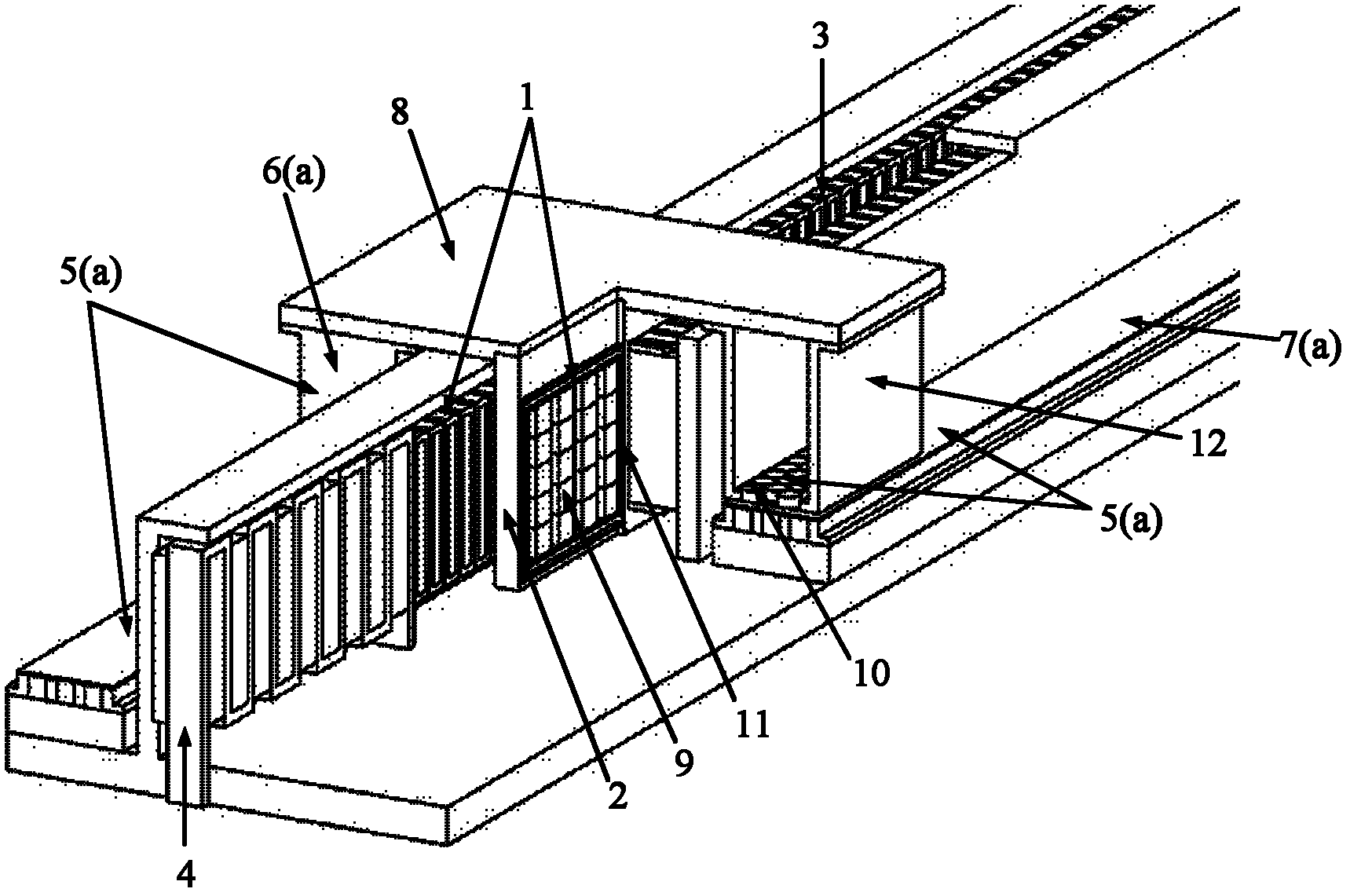

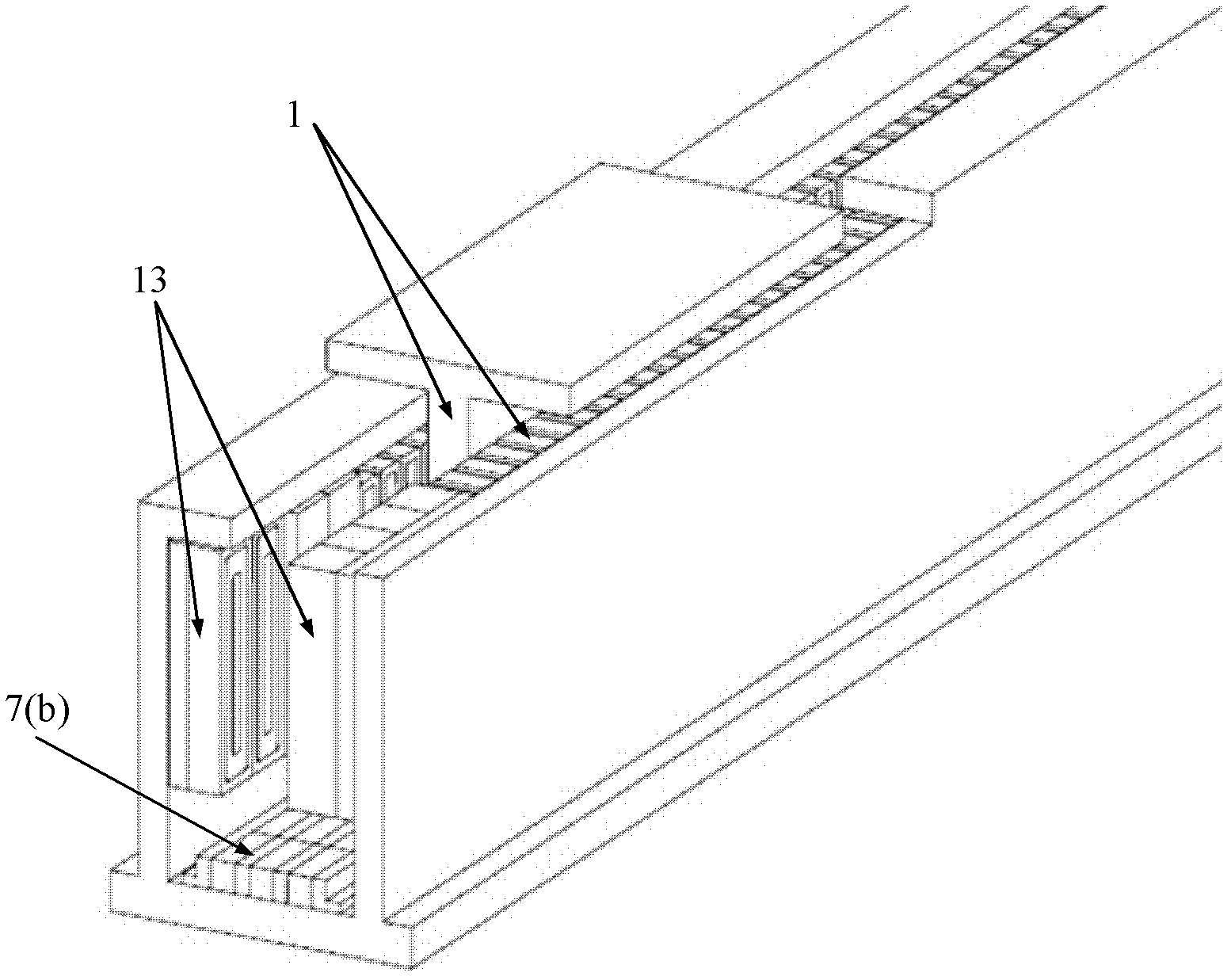

[0027] The overall structure of this embodiment two is basically the same as that of embodiment 1, as image 3 , 4 and Figure 6 As shown, it consists of a bilateral high-temperature superconducting linear synchronous motor 1, a high-temperature superconducting magnetic levitation subsystem 5(b) and a split-type pulse coil magnetizing device 13(b) using YBCO high-temperature superconducting coil magnets. The only difference is : The bilateral high-temperature superconducting linear synchronous motor 1 is located in the upper part of the system, the high-temperature superconducting magnetic levitation subsystem 5 (b) is located in the lower part of the system, and the levitation mover 6 (b) of the high-temperature superconducting magnetic levitation subsystem 5 (b) is connected to The secondary mover 2 of the double-sided high-temperature superconducting linear synchronous motor 1 is connected as a whole; two pairs of split-type pulse coil magnetization devices 13(b) that can ...

Embodiment 3

[0029] The overall structure of the third embodiment is basically the same as that of the second embodiment, the only difference is that two pairs can be used to achieve cross-pole magnetization, the polarity after magnetization is the same, and MgB 2 The split pulse coil magnetizing device 13(c) of the superconducting coil magnet 14(c), such as Figure 7 shown. The magnetization process is basically the same as that in Example 2, the only difference is that after one magnetization is completed, the two non-adjacent high-temperature superconducting block magnet arrays (9) in (2) can be realized at the same time. The magnetization of two high-temperature superconducting bulk arrays, and the polarity of the two magnetic poles after magnetization are the same. After one magnetization is completed, the next two unmagnetized high-temperature superconducting bulk arrays in (2) are moved to the separate arrays. The bulk-type pulse coil magnetization device (13(c)) completes the magn...

Embodiment 4

[0031] The overall structure of this embodiment is basically the same as that of Embodiment 1, consisting of a double-sided high-temperature superconducting linear synchronous motor (1), a high-temperature superconducting magnetic levitation subsystem (5 (a)) and a split-type pulse using YBCO high-temperature superconducting coil magnets Coil magnetizing device (4), the only difference is: the split type pulse coil magnetizing device (4) is composed of two parallel S-shaped winding pulse coil groups using YBCO strips. Each S-shaped pulse charging coil can generate a pair of poles with opposite polarity pulse magnetic field, and the span of each S-shaped pulse charging coil is equal to one of the high-temperature superconducting bulk magnet array (9) in (1). The length of the poles.

[0032] When magnetizing, move the secondary mover (2) installed with the high-temperature superconducting block magnet array (9) in (1) to the split type pulse coil magnetizing device (4), so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com