Rubber composition and pneumatic tire using the same

A rubber composition and rubber technology, applied in special tires, tire parts, transportation and packaging, etc., to achieve excellent driving stability and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

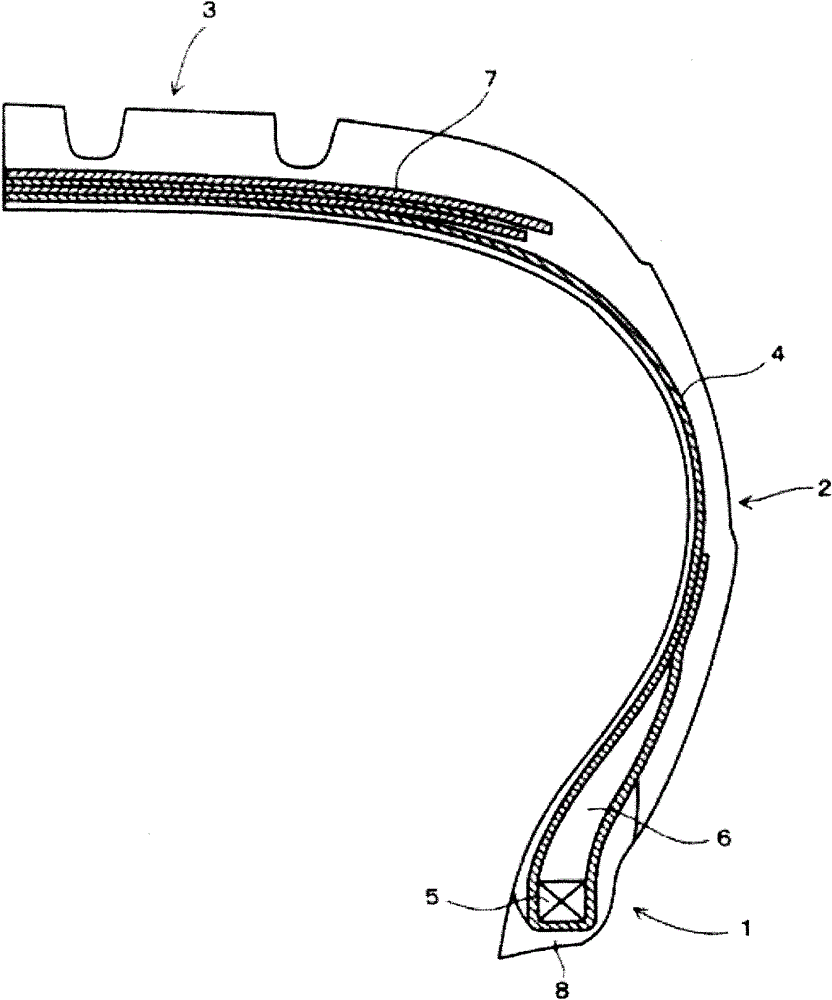

Image

Examples

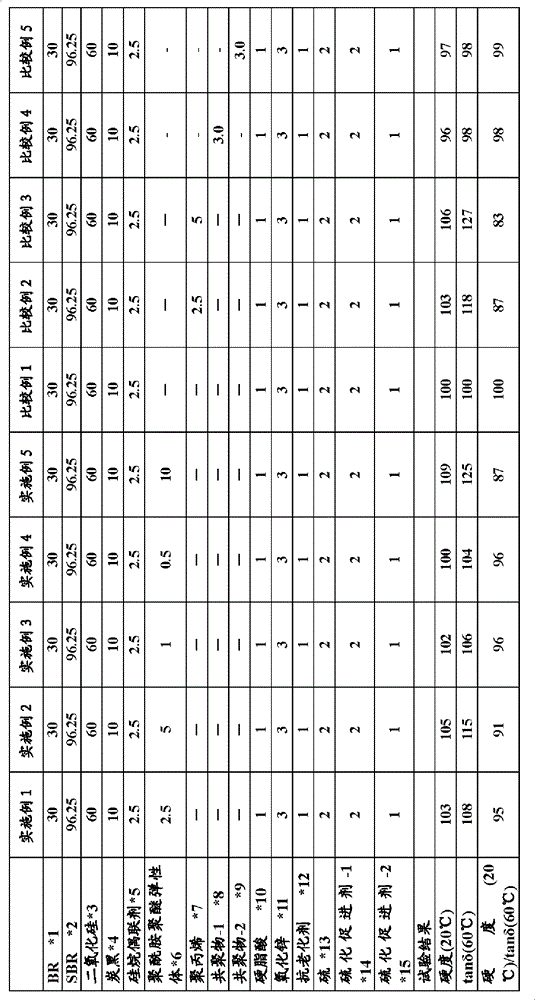

Embodiment 1~5 and comparative example 1~5

[0046] Sample preparation

[0047]Components other than the vulcanization system (vulcanization accelerator, sulfur) in the compounding (parts by mass) shown in Table 1 were put into a 1.7-liter closed-type Banbury mixer and kneaded for 5 minutes at 165° C. Release from the mill and cool at room temperature. Next, this composition was put into an open roll, and a vulcanizing system was added and kneaded to obtain a rubber composition. Next, the obtained rubber composition was placed in a predetermined mold and vulcanized under pressure at 160° C. for 20 minutes to prepare a vulcanized rubber test piece. The physical properties of the obtained vulcanized rubber test pieces were measured according to the test methods shown below.

[0048] Hardness (20°C): Measured at 20°C in accordance with JIS 6253. The result is a value shown when the value of Comparative Example 1 is taken as an index of 100. The larger the index, the higher the hardness and the better the driving stabili...

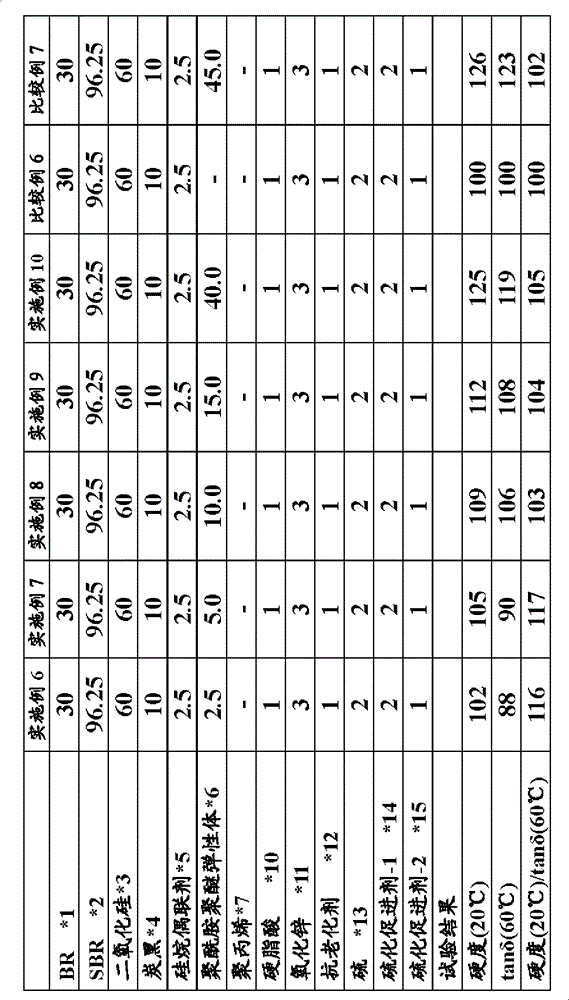

Embodiment 6~10 and comparative example 6~7

[0052] Sample preparation

[0053] In the compounding (parts by mass) shown in Table 2, only BR, SBR, silicon dioxide and silane coupling agent were charged into a 1.7-liter closed-type Banbury mixer and mixed for 2 minutes at 165°C. Make diene-based rubber and silica undergo coupling and multiplication reaction, then add other ingredients except the above-mentioned ingredients and sulfur-based (vulcanization accelerator, sulfur) and knead at 150°C for 3 minutes, release from the internal mixer, and store at room temperature cool down. Next, this composition was put into an open roll, and a vulcanizing system was added and kneaded to obtain a rubber composition. Next, the obtained rubber composition was placed in a predetermined mold and vulcanized under pressure at 160° C. for 20 minutes to prepare a vulcanized rubber test piece. The physical properties of the obtained vulcanized rubber test pieces were measured according to the test methods shown above. In addition, the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| vibrational frequency (mechanical) | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com