Radiation curable silicone composition

A technology of composition and siloxane, applied in the direction of coating, etc., can solve the problem of not realizing high-speed curing, and achieve the effect of high-speed curing and high photosensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] To 100 parts by weight of the cationically polymerizable organopolysiloxane (a) corresponding to component (A) of the present invention represented by the following average composition formula (a):

[0055]

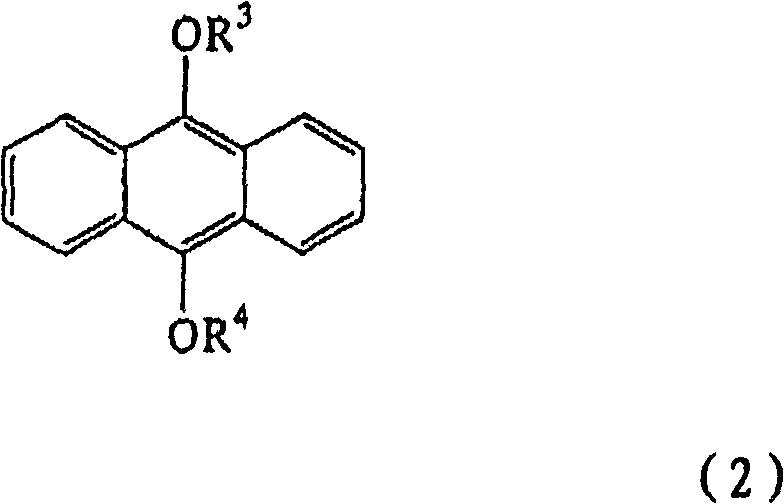

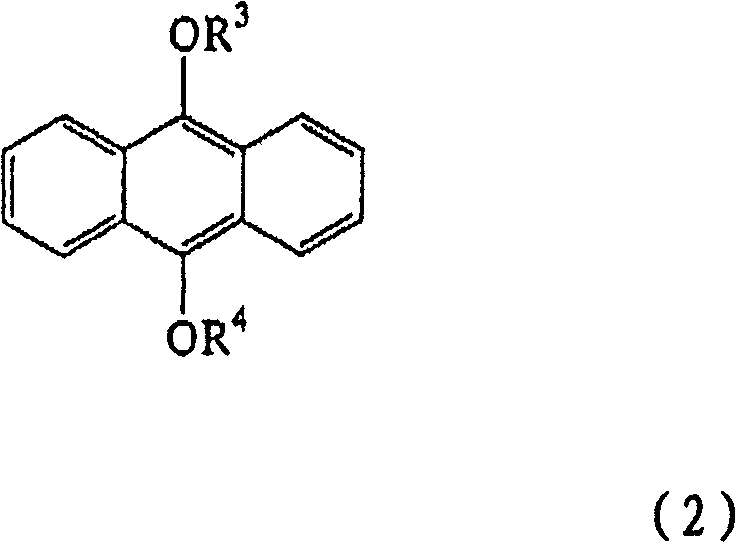

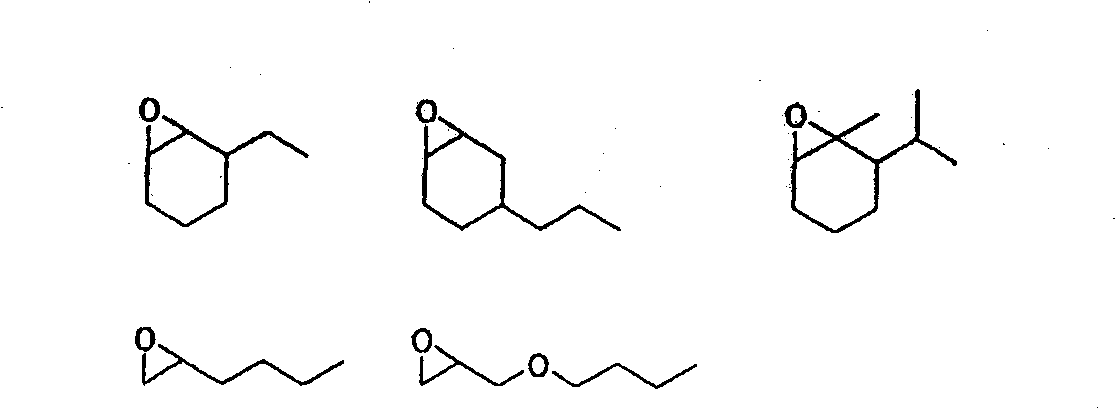

[0056] Wherein 6.5mol% of all organic groups are monovalent epoxy functional organic groups, and have a viscosity of 90mPa.s at 25°C, add 1.0 parts by weight of toluene solution to dissolve 50% by weight corresponding to the component of the present invention ( B) Bis[4-alkyl (C 10 -C 13 ) phenyl]iodonium hexafluoroantimonate (e), and 7.6% by weight of 9,10-dibutoxyanthracene (f) corresponding to component (C) of the present invention is added, and the mixture is uniformly stirred To prepare radiation curable silicone composition 1. This radiation curable silicone composition 1 was cured as described above, and the cured properties were determined by finger touch. The results are shown in Table 1. The peel strength of the film obtained by curing the radiatio...

Embodiment 2

[0058] To 100 parts by weight of the cationically polymerizable organopolysiloxane (d) corresponding to component (A) of the present invention represented by the following average composition formulas (b) and (c):

[0059]

[0060] Wherein 3.7mol% of all organic groups are monovalent epoxy functional organic groups, and have a viscosity of 150mPa.s at 25°C, add 1.0 parts by weight of toluene solution to dissolve 50% by weight of the components corresponding to the present invention (B) two [4-alkyl (C) as photoacid generator 10 -C 13 ) phenyl]iodonium hexafluoroantimonate (e), and 7.6% by weight of 9,10-dibutoxyanthracene (f) corresponding to component (C) of the present invention is added, and the mixture is uniformly stirred To prepare radiation curable silicone composition 2. This radiation curable silicone composition 2 was cured as described above, and the cured properties were determined by finger touch. The results are shown in Table 1. The peel strength of the f...

Embodiment 3

[0062] To 100 parts by weight of the organopolysiloxane (a) of Example 1, add 1.0 parts by weight of the toluene solution to dissolve 50% by weight of bis[4- Alkyl (C 10 -C 13 ) phenyl] iodonium hexafluoroantimonate (e), and 9,10-bis(2-ethylhexyloxy)anthracene (g) corresponding to component (C) of the present invention added in an amount of 7.6% by weight , and the mixture was uniformly stirred to prepare radiation curable silicone composition 3. This radiation curable silicone composition 3 was cured as described above, and the cured properties were determined by finger touch. The results are shown in Table 1. The peel strength of the film obtained by curing the radiation-curable silicone composition 3 was also measured according to the evaluation method described above. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com