Unidirectional flow project for seawater in high-level downflow weirs

A one-way flow and overflow weir technology, which is applied in river regulation and climate change adaptation, can solve the problems of complicated operation management, labor, time and energy consumption, and high breeding costs, and achieve simple and convenient operation and management with obvious effects , Obvious effect of energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

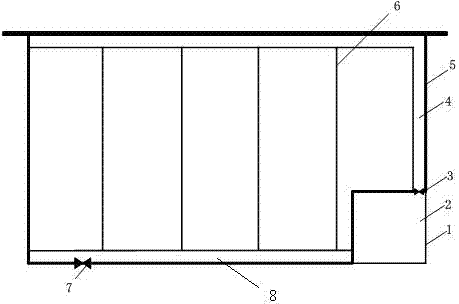

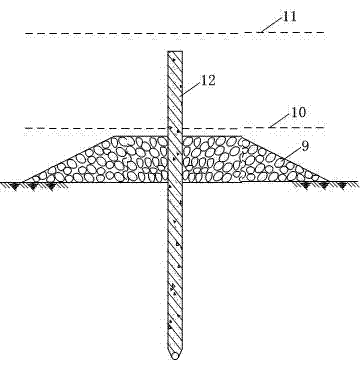

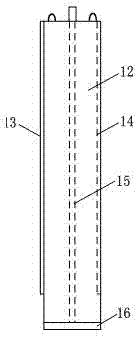

[0014] refer to figure 1 — Figure 4 , a high-level overflow weir seawater one-way flow project, including a high-level overflow weir 1, a tide-receiving reservoir 2, an intake gate or an intake culvert 3, a main water delivery channel 4, a tide-proof dam 5, a branch channel 6, a drainage gate 7, Drainage main canal 8, riprap slope protection 9. A tide-proof dam 5 and a high-level overflow weir 1 are built on coastal tidal flats and shallow waters to form a tide-receiving reservoir 2 . The top elevation of the high overflow weir 1 is lower than the local high tide water level 11 during high tide and higher than the local low tide water level 10 during ebb tide. The high-level overflow weir 1 is a continuous wall structure with reinforced concrete slabs. The tide-receiving reservoir 2 is formed after the high-level overflow weir 1 and 5 anti-tidal dams surround it. The tide receiving reservoir 2 is provided with a water intake gate or a water intake culvert 3 connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com