Heat radiating device

A technology of heat dissipation device and radiator, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as unfavorable heat transfer, exposure of heat pipes to the outside world, and reduction of heat dissipation area of heat dissipation devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

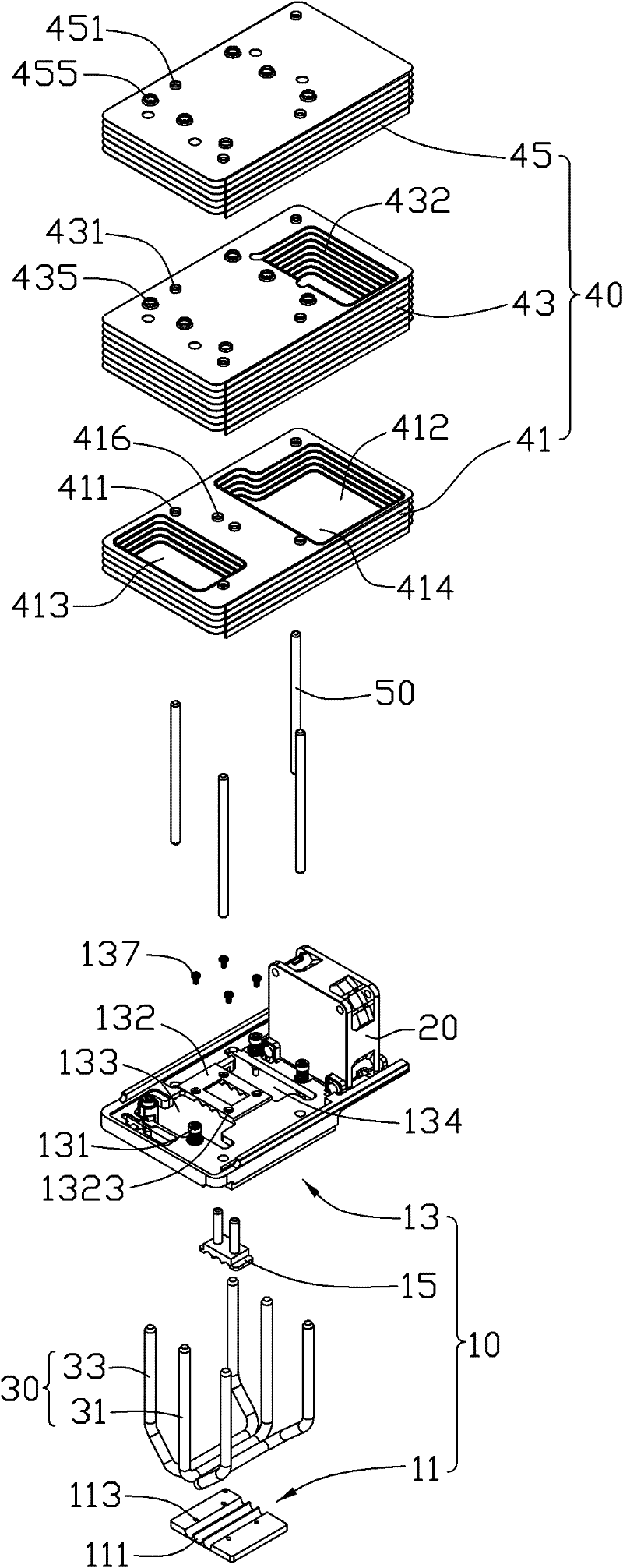

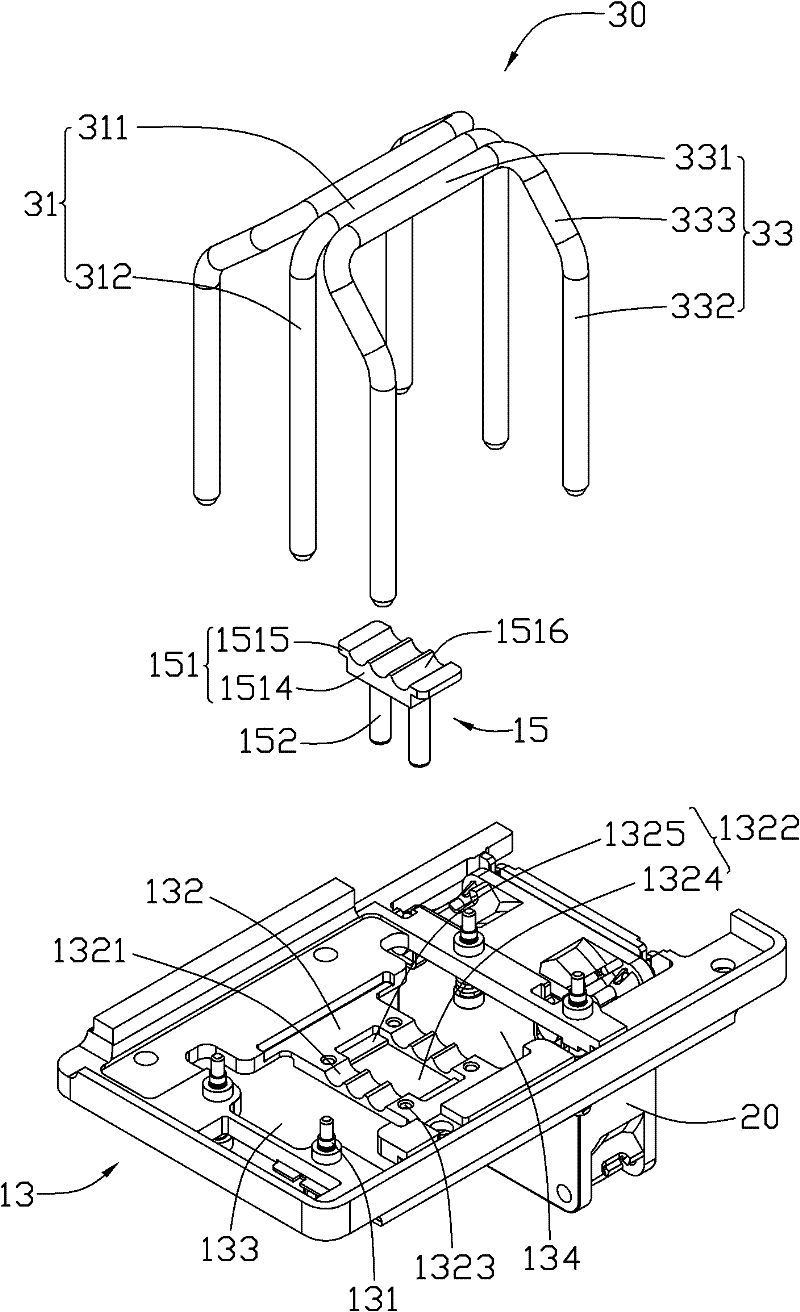

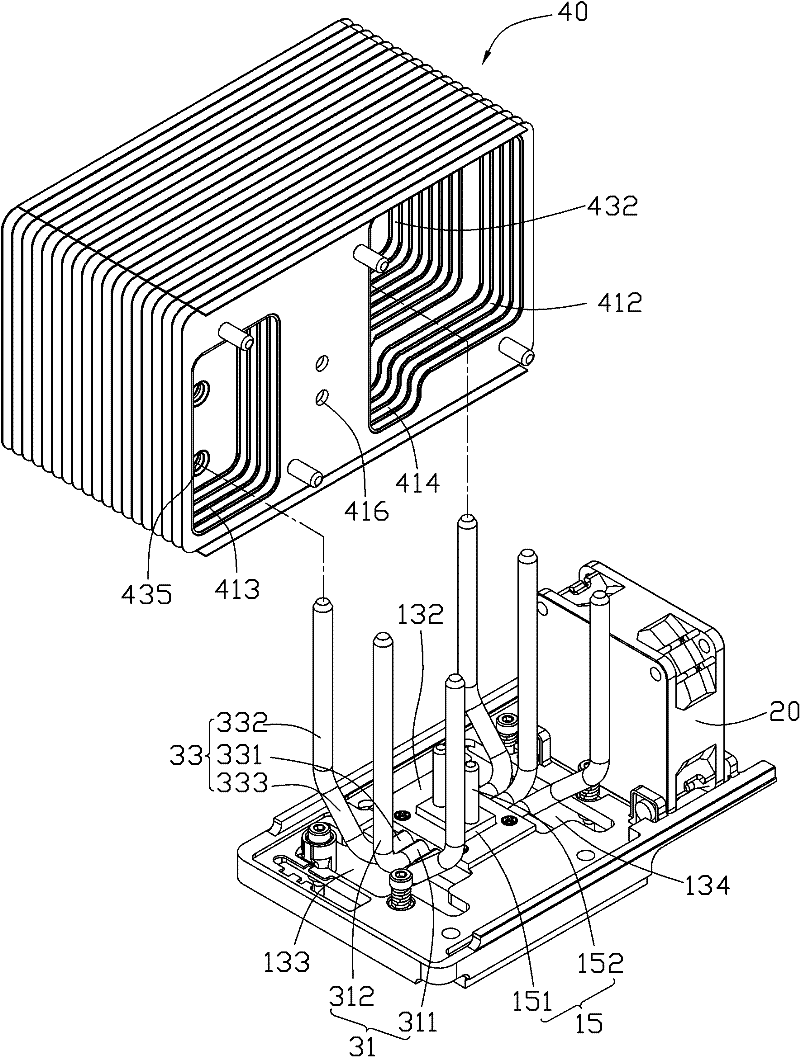

[0050] figure 1 and figure 2 Shown is the heat dissipation device in the first embodiment of the present invention, which is used to dissipate heat from a heat-generating electronic component (not shown) such as a central processing unit. The heat dissipation device includes a base 10, a fan 20 placed on the base 10, a heat pipe assembly 30 combined with the base 10, a radiator 40 combined with the heat pipe assembly 30, and a radiator 40 inserted through the radiator. Several conductive rods 50 in 40.

[0051] The base 10 includes a substrate 11 , a fixing frame 13 and a heat transfer element 15 combined on the substrate 11 .

[0052] The substrate 11 is rectangular and made of materials with good thermal conductivity such as copper and aluminum. The lower surface of the substrate 11 is used for thermal contact with the heat-generating electronic components, and the middle of the upper surface is provided with a plurality of parallel spaced semicircular receiving grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com