Equipment for integrally treating oil-water separation of kitchen garbage

A technology for oil-water separation and kitchen waste, which is applied in the direction of garbage cans, garbage collection, and immiscible liquid separation, etc., can solve the problems of high cost, high investment, and harm to human beings, and achieve low operating costs, high economic benefits, and The effect of low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

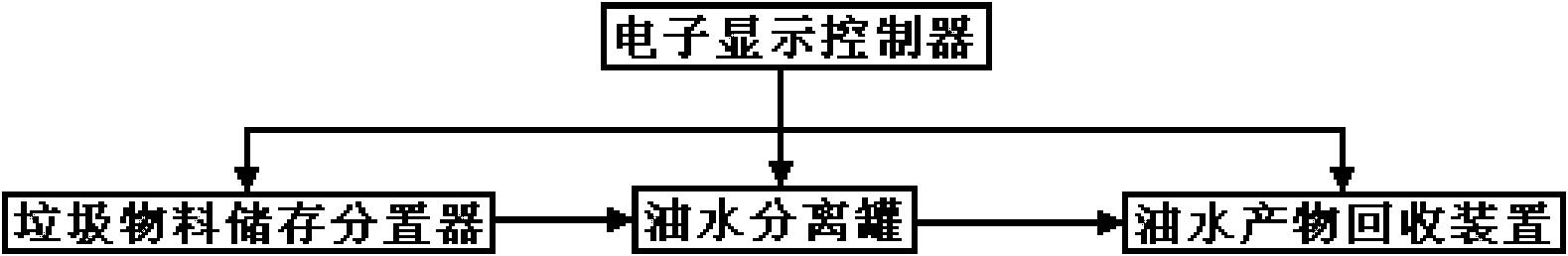

[0042] An integrated processing equipment for oil-water separation of food waste, including an electronic display controller, characterized in that it also includes a waste material storage and dispensing device, an oil-water separation tank, and an oil-water product recovery device respectively connected to the electronic display controller; wherein, The four parts of the electronic display controller, the garbage material storage separator, the oil-water separation tank and the oil-water product recovery device work together, and the electronic display controller is used for real-time monitoring of the garbage material storage separator, the oil-water separation tank and the oil-water product recovery device. The feed and discharge of the recovery device, and complete the integrated treatment process of kitchen waste oil-water separation in the following way:

[0043] (1) The waste material storage separator includes a U-shaped or V-shaped housing, two sealing covers, a first...

Embodiment 2

[0047] An integrated processing equipment for oil-water separation of food waste, including an electronic display controller, characterized in that it also includes a waste material storage and dispensing device, an oil-water separation tank, and an oil-water product recovery device respectively connected to the electronic display controller; wherein, The four parts of the electronic display controller, the garbage material storage separator, the oil-water separation tank and the oil-water product recovery device work together, and the electronic display controller is used for real-time monitoring of the garbage material storage separator, the oil-water separation tank and the oil-water product recovery device. The feed and discharge of the recovery device, and complete the integrated treatment process of kitchen waste oil-water separation in the following way:

[0048] (1) The waste material storage separator includes a U-shaped or V-shaped housing, two sealing covers, a first...

Embodiment 3

[0052] An integrated processing equipment for oil-water separation of food waste, including an electronic display controller, characterized in that it also includes a waste material storage and dispensing device, an oil-water separation tank, and an oil-water product recovery device respectively connected to the electronic display controller; wherein, The four parts of the electronic display controller, the garbage material storage separator, the oil-water separation tank and the oil-water product recovery device work together, and the electronic display controller is used for real-time monitoring of the garbage material storage separator, the oil-water separation tank and the oil-water product recovery device. The feed and discharge of the recovery device, and complete the integrated treatment process of kitchen waste oil-water separation in the following way:

[0053] (1) The waste material storage separator includes a U-shaped or V-shaped housing, two sealing covers, a first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com