Accurate extrusion mould and method of light alloy stepped workpiece

An extrusion die and ladder-shaped technology, which is applied in the field of precise extrusion dies for ladder-shaped workpieces, can solve the problems of difficult-to-form multi-layer twists and turns, low strength, and low guiding precision, and achieve shortened manufacturing processes, high material utilization, and The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

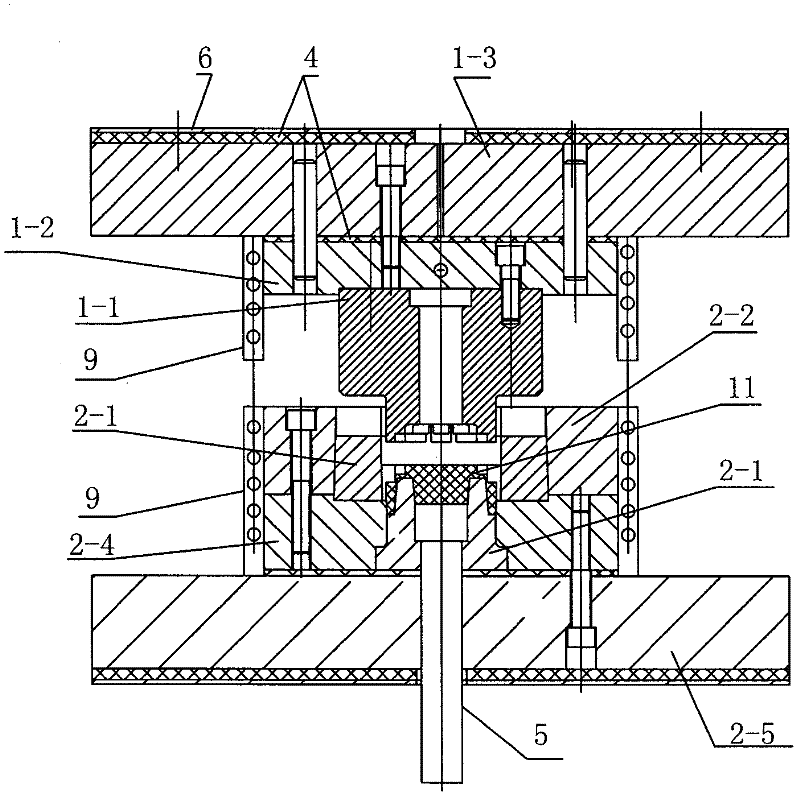

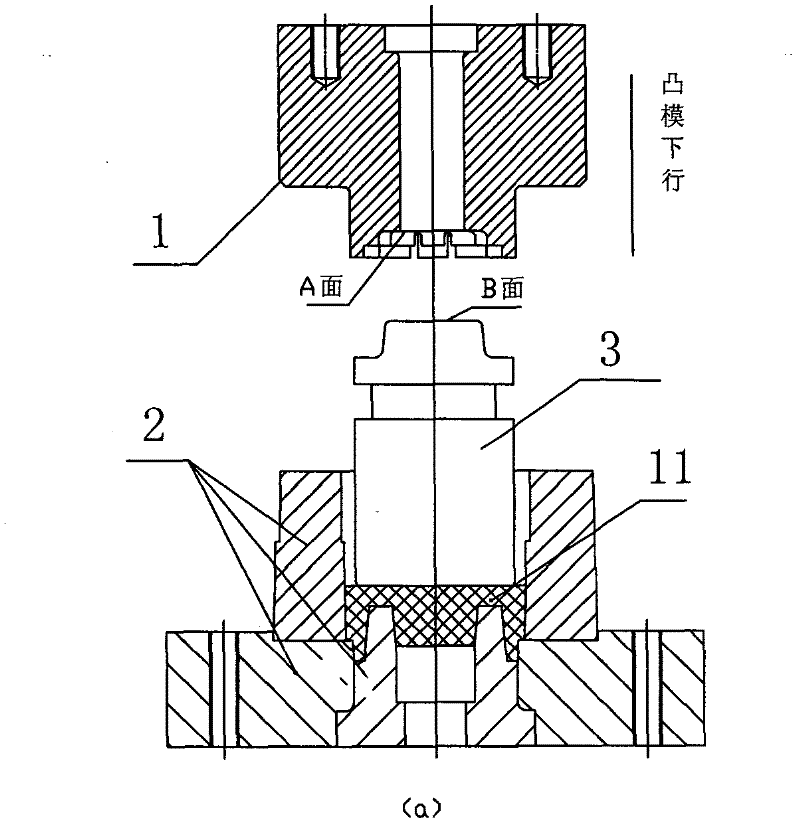

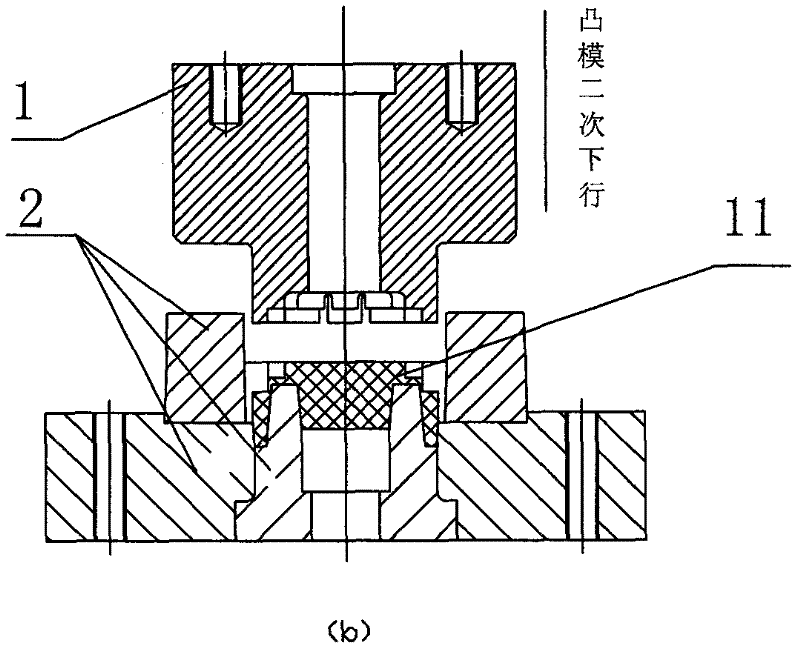

[0026] One, the precise extruding mold of light alloy stepped workpiece of the present invention

[0027] figure 1 , Figure 10 and Figure 11 As shown, the precise extrusion die of light alloy stepped workpiece ( figure 1 for mold clamping state). The mold includes a male mold part 1 , a female mold part 2 and a pre-press core 3 . Described punch part 1 is made up of punch 1-1, upper backing plate 1-2 and upper template 1-3; The positioning pin is connected, and the upper formwork and the press are connected by bolts; a heat-insulating cotton pad (4) is provided between the upper backing plate and the upper formwork, and a heat-insulating cotton clamp pad 4 and an iron sheet are provided between the upper formwork and the press. 6.

[0028] The die part 2 is composed of a die ring 2-1, an insert 2-2 with a cavity, a stress ring 2-3, a lower backing plate 2-4 and a lower template 2-5; the insert is placed in the die There is a constrained stress circle inside the circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com