Method for producing high-strength wood structure engineering material

A wooden structure and manufacturing method technology, applied in the direction of manufacturing tools, wood processing appliances, flat products, etc., can solve the problems of the influence of the bonding strength of the glued surface, difficulty in forming glue nails, insufficient penetration depth of the adhesive, etc., and achieve the effect of improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

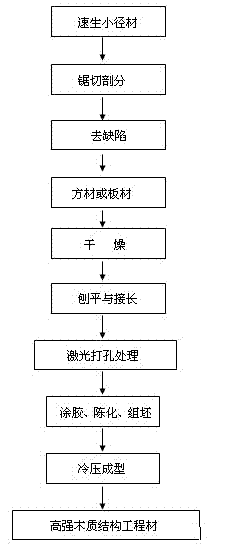

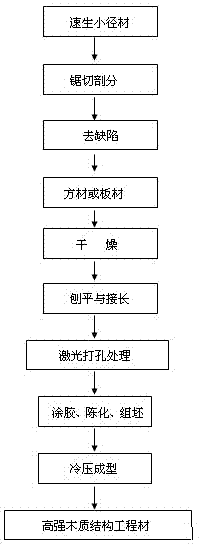

[0019] 1. Cut the small-diameter fast-growing wood into boards with a thickness of 30-50mm by a band saw, and then cut off and remove defects such as knots and decay in the boards by a hanging cut-off saw;

[0020] 2. Send the defect-removed board into a drying kiln to dry to a moisture content of about 10%, and then balance it in an indoor environment for 1 week.

[0021] 3. Send the dried board to the double-sided planer for surface processing, improve the flatness and smoothness of the board surface, and perform thickness-setting treatment on the board, and then lengthen the short material by finger-joining.

[0022] 4. Send the plate after the thickness setting treatment to the flexible laser punching machine, and punch holes on the upper and lower surfaces of the plate. The laser power is 500w, the feeding speed is 10mm / s, and micropores with a diameter of about 0.01-0.03mm and a depth of 0.05-2mm are obtained.

[0023] 5. Adjust the resorcinol adhesive to a concentratio...

Embodiment 2

[0027] 1. Cut the small-diameter fast-growing wood into squares with a thickness of 51-100mm by a band saw, and then cut off and remove defects such as knots and decay in the board by a hanging cut-off saw;

[0028] 2. Send the defect-removed squares into the drying kiln to dry to a moisture content of about 10%, and then balance in the indoor environment for 1 week.

[0029] 3. The surface of the dried square is processed by double-sided planing to improve the flatness and smoothness of the surface of the plank, and the thickness of the square is fixed, and then the short is lengthened by finger jointing.

[0030] 4. Send the thickness-fixed square material into the flexible laser punching machine, and punch holes on the upper and lower surfaces of the square material. The laser power is 1000w, the feeding speed is 5mm / s, and the micropores with a diameter of about 0.04-0.06mm and a depth of 0.1-4mm are obtained.

[0031] 5. Adjust the concentration of resorcinol adhesive to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com