External refining method of industrial silicon

A silicon furnace and industrial technology, which is applied in the field of refining outside the industrial silicon furnace to achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

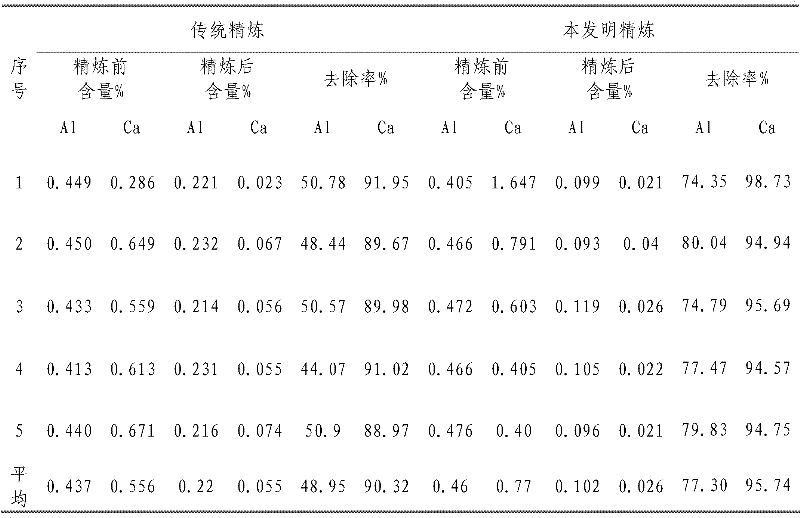

Examples

Embodiment Construction

[0010] The submerged arc furnace releases the molten silicon liquid with a silicon content greater than 98% and discharges it into the silicon bag blowing oxygen at the bottom. Before the silicon water flows into the silicon bag, turn on the compressed air at 350L / min and ensure that the air pipe is unblocked. When the silicon liquid flows into the silicon bag After bagging, feed oxygen and control the oxygen flow rate to 700L / min. When the amount of silicon liquid reaches 2000Kg, use a digital display thermometer to measure the temperature of the silicon liquid. Add calcium stone 33-50Kg. During operation, make sure that the added calcium stone is in a molten state, otherwise adding calcium stone will be invalid. When the silicon liquid in the silicon bag reaches 5000kg, measure the temperature of the silicon liquid again, and use the method of increasing cold silicon to reduce the temperature. Silicon liquid temperature or adjust the air + oxidation ratio to strengthen the ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com