Aqueous dispersion system and method for etching polysilicon wafer

A technology for water-based dispersion and polycrystalline silicon wafers, which is applied to the etching field of water-based dispersion systems and polycrystalline silicon wafers, and can solve problems such as increased cost and production environment hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085] Below in conjunction with embodiment further illustrate this patent application. Those skilled in the art can understand that the scope of this patent application is not limited thereto.

[0086] The polycrystalline silicon wafers used in the following comparative examples and examples were all purchased from Konca Solar Cell Co., Ltd.

Embodiment 1

[0092] Weigh 25 mg of analytically pure bismuth hydroxide powder and put it into a beaker filled with 50 ml of deionized water. Ultrasonic breaker (SONICS, Vibro-cell TM VCX 130) dispersed for 30min, then added 0.5mg of C 18 h 29 SO 3 Na surfactant and 1 mg of C 16 f 33 C 2 h 4 (C 2 h 4 O) 8 Surfactant H, continue to sonicate for 2 hours to obtain an aqueous dispersion.

[0093] The same polycrystalline silicon wafer as in Comparative Example 1 was etched using the etching method described in Comparative Example 1 but using the aqueous dispersion system obtained in this example.

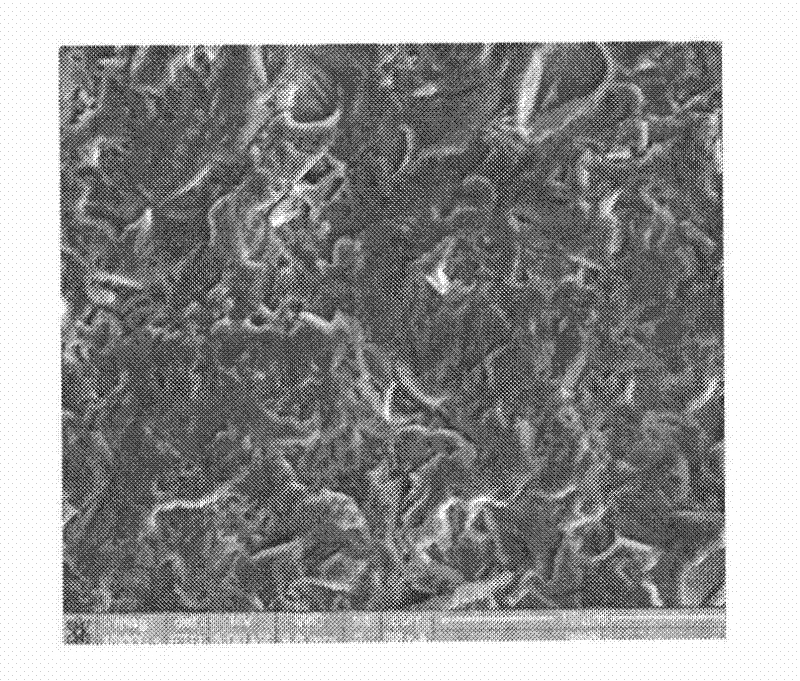

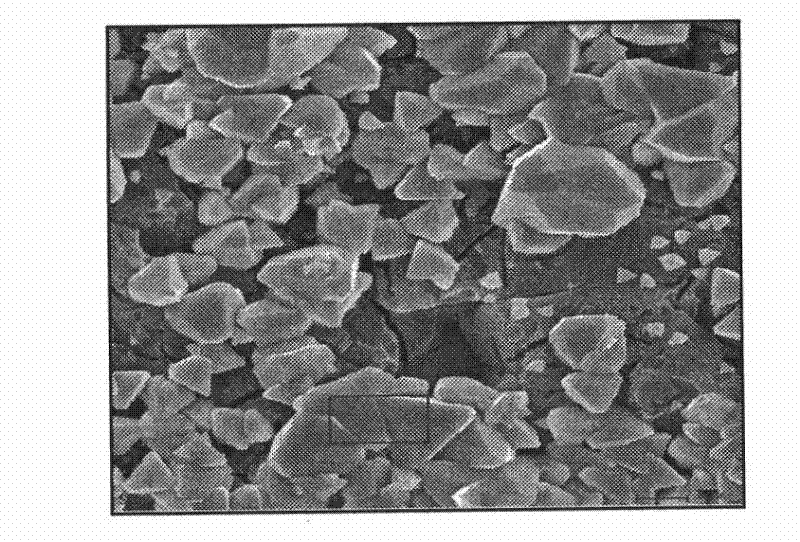

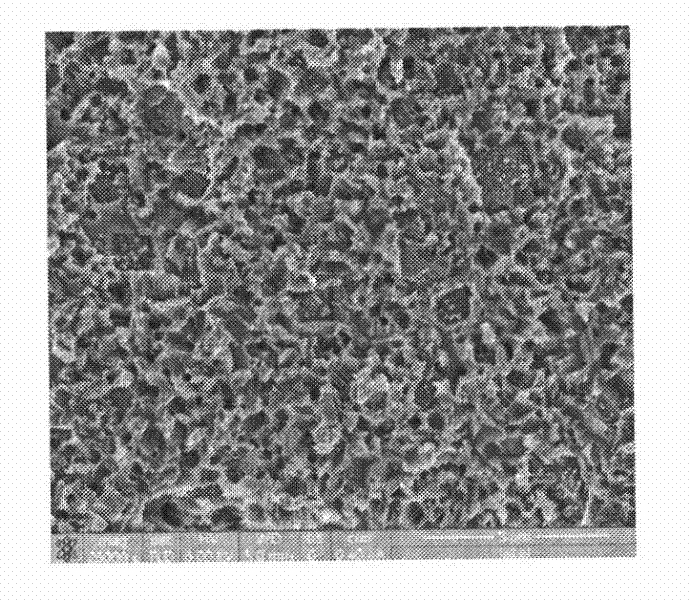

[0094] Using FEI NOVA200NanoLab SEM FIB scanning electron microscope (magnification 25000x) to observe the surface morphology of the polycrystalline silicon wafer before and after etching, the results are as follows figure 2 shown. It can be seen from the figure that the surface of the polycrystalline silicon wafer has a uniform and fine textured structure. The average reflectance (mea...

Embodiment 2

[0096] Using the dispersion method described in Example 1, 25 mg of analytically pure bismuth hydroxide powder, 0.5 mg of CH 3 (CH 2 ) 10 CH 2 SO 3 Na surfactant and 1 mg of C 16 f 33 C 2 h 4 (C 2 h 4 O) 8 The H surfactant was dispersed in 50 ml of deionized water to obtain an aqueous dispersion system.

[0097] The same polycrystalline silicon wafer as in Comparative Example 1 was etched using the etching method described in Comparative Example 1 but using the aqueous dispersion system obtained in this example.

[0098] A UV-Vis spectrophotometer (Perkin Elmer Lamda 950) was used to measure the change in reflectance before and after etching, as shown in image 3 As shown, the reflectance of the etched polysilicon wafer has a significant decrease.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com