Method and device for selecting magnetic levitation driven needle

A magnetic levitation, electromagnetic drive technology, applied in knitting, weft knitting, textiles and papermaking, etc., to reduce the temperature coefficient, improve electrical conductivity and relative sealing, increase capacitance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Markings in the attached drawings:

[0012] attached figure 1 , attached figure 2 Among them, 1—knitting needle, 3—needle shell.

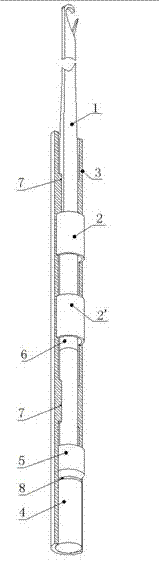

[0013] attached image 3 Among them, 2—fixed pole piece, 2’—fixed pole piece, 3—needle shell, 4—electromagnetic drive device, 5—permanent magnet, 6—moving pole piece, 7—radial support surface, 8—rubber sheet.

[0014] attached Figure 4 Middle, 2—fixed pole piece A, 9—equal potential ring, 10—ceramic material base, 11—silver coating, 12—rhodium coating, 13—polyethylene coating, 14—ceramic material base, 15—silver coating, 16— Rhodium plating.

[0015] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0016] as attached figure 1 and 2 As shown, it is the middle knitting needle of the computerized jacquard circular weft machine, and the rest are outer knitting needles and inner knitting needles. The inner and outer knitting needles are only the knitting needle heads that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com