Gluing clearance adjustment system of carbon fiber prepreg machine

A carbon fiber prepreg and gap adjustment technology, which is applied in liquid/gas/steam fiber/sliver/roving processing, textile processing machine accessories, textiles and papermaking, etc., can solve the problem of low precision and inconvenient adjustment of prepreg thickness control and other issues, to achieve the effect that is conducive to precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

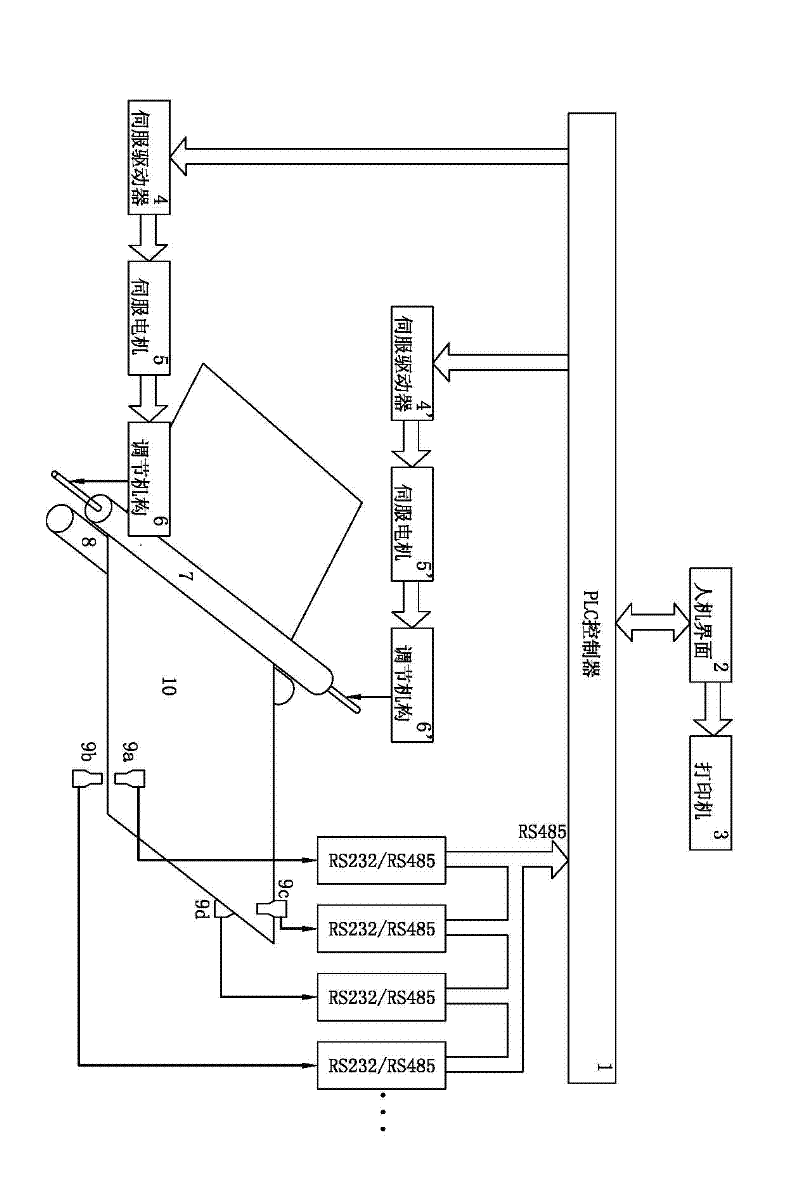

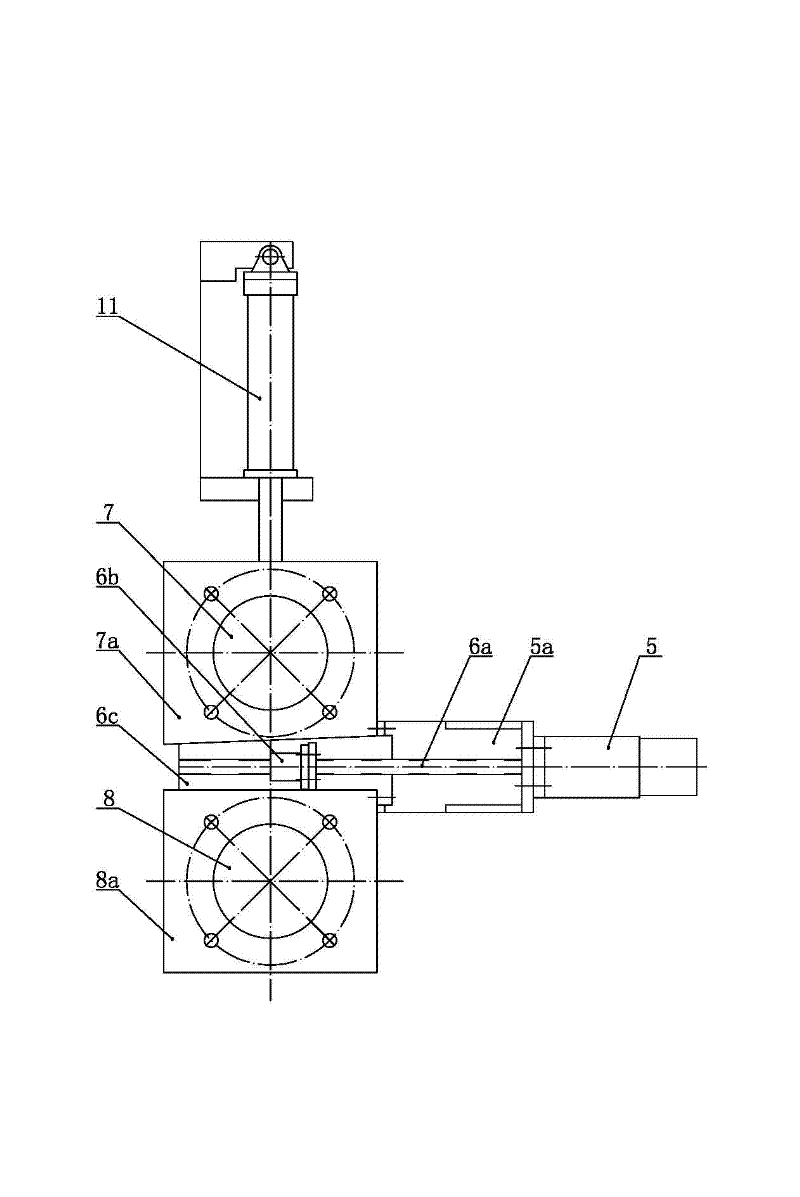

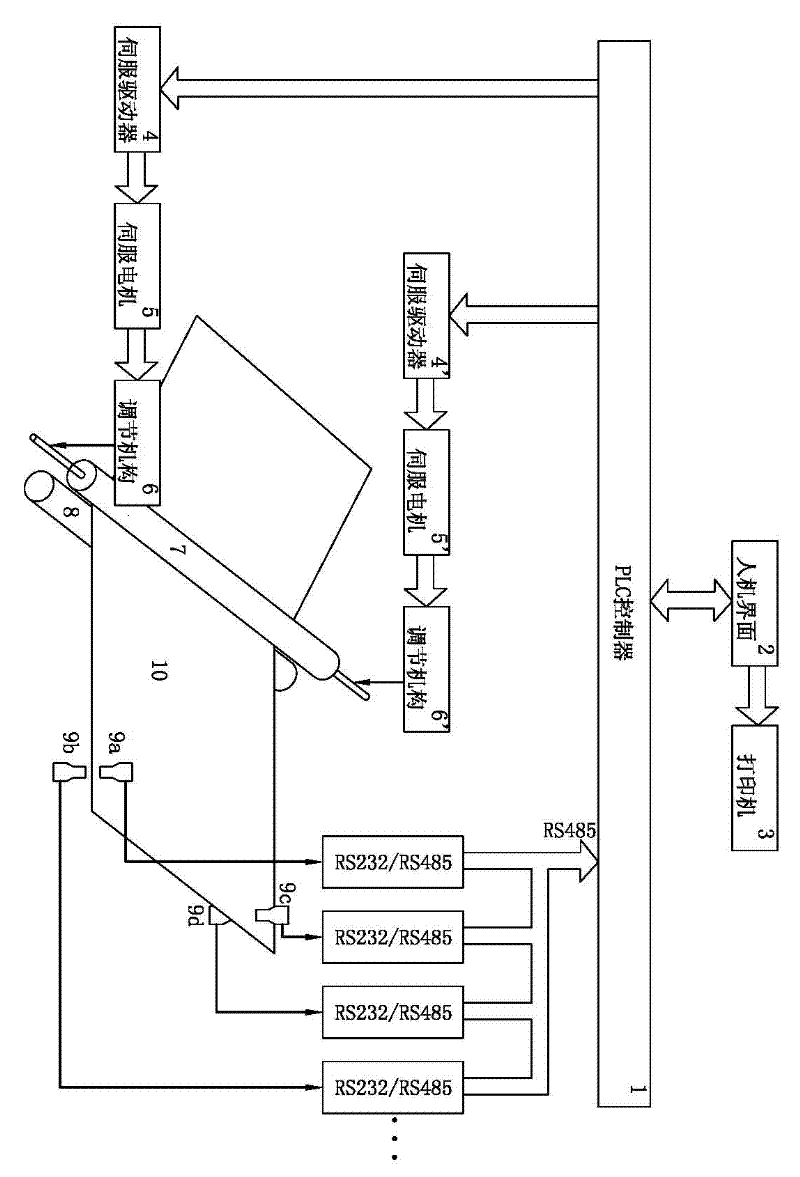

[0015] Such as figure 1 and figure 2 As shown, the carbon fiber prepreg machine gluing gap adjustment system of the present invention includes an upper heating roller 7 and a lower heating roller 8, the upper heating roller 7 is located above the lower heating roller 8 and the two are parallel to each other, and the carbon fiber prepreg 10 from the upper It passes between the heating roller 7 and the lower heating roller 8, and also includes a PLC controller 1, a man-machine interface 2, a printer 3, a servo driver 4, 4', a servo motor 5, 5', and detecting the thickness of the carbon fiber prepreg cloth after rolling The thickness detection probes 9a, 9b, 9c, 9d input the carbon fiber cloth thickness setting value to the PLC controller 1 through the man-machine interface 2. The thickness detection probes 9a, 9b, 9c, and 9d connect the detected carbon fiber cloth thickness values to the RS485 input end of the PLC controller through the RS232 / RS485 conversion joint, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com