Ion exchange resin cleaning tower for uranium hydrometallurgy fixed bed

A technology of ion exchange resin and fixed bed, which is applied in special equipment for dispersing hardened resin and cleaning poisoned resin, and in the field of sediment. It can solve the problems of unclean sediment cleaning, inability to separate resin, and large resin loss, etc., and achieve resin loss rate. Small size, low breakage rate and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

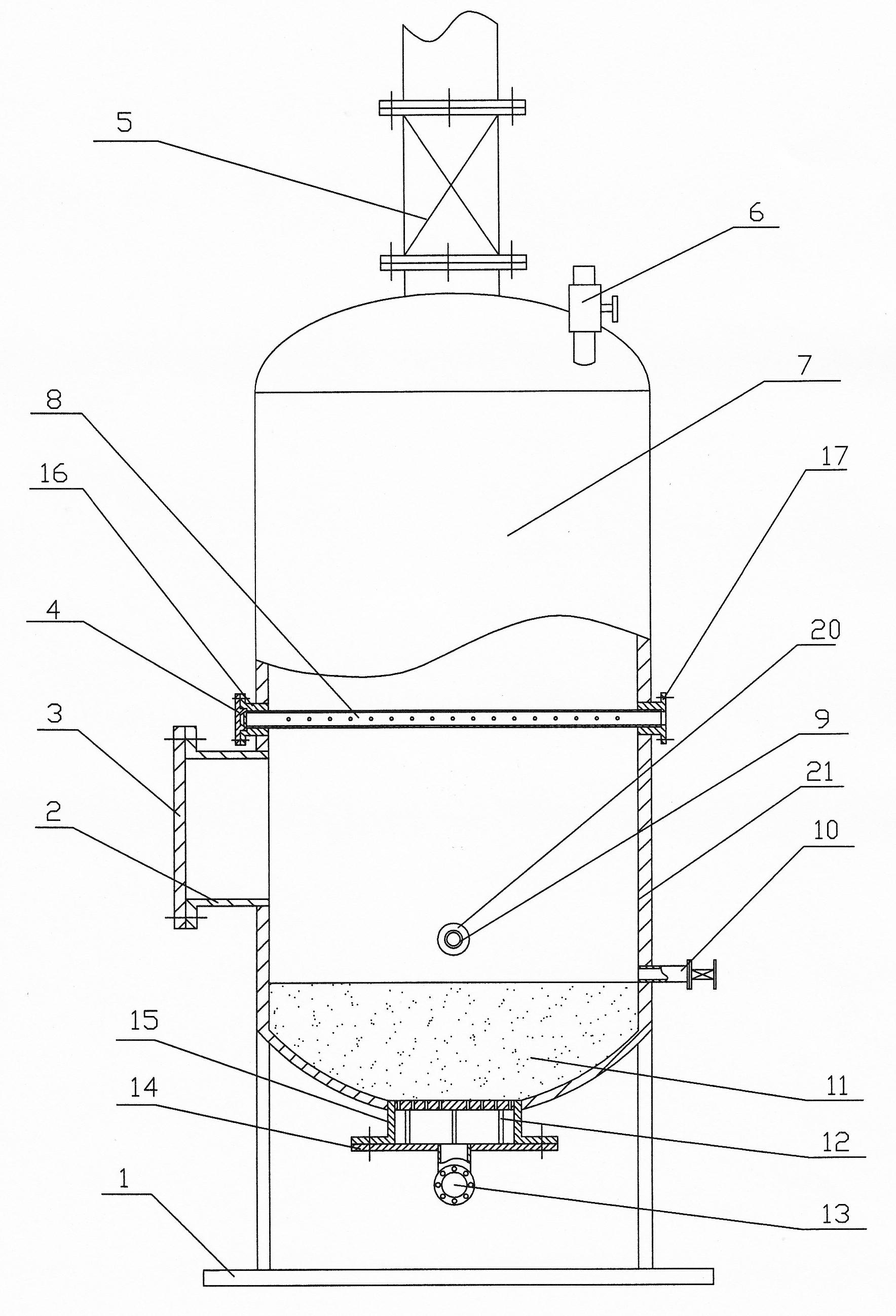

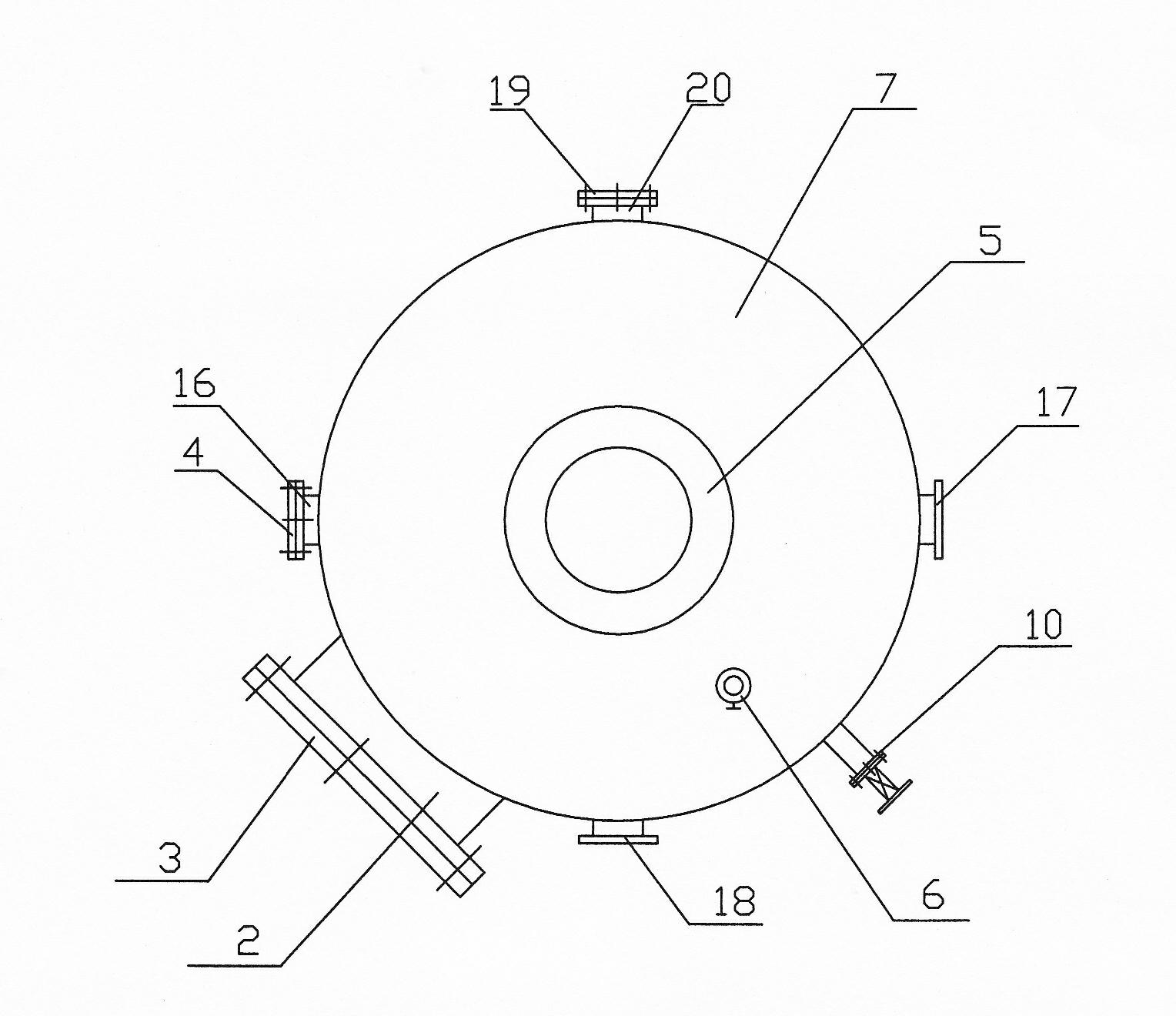

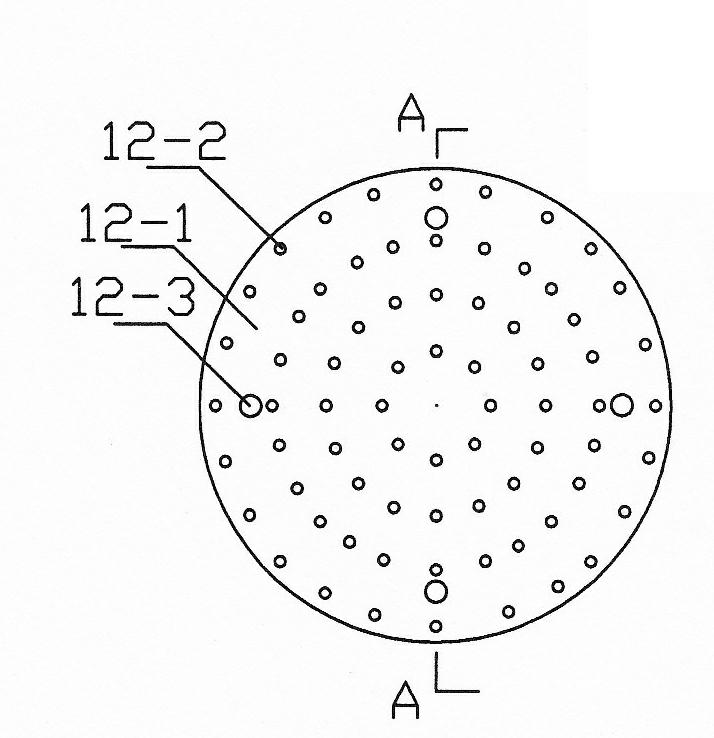

[0020] A fixed bed ion exchange resin cleaning tower for uranium hydrometallurgy, which includes a tower body 7 and a base 1, the tower body 7 is fixedly installed on the base 1, and the inner wall of the tower body 7 is lined with a PO glue anti-corrosion layer 21. The bottom of the tower body 7 is provided with a liquid outlet pipe 15, and the liquid outlet pipe 15 is provided with a liquid outlet pipe cover plate 14 with a recoil water inlet and outlet joint 13, and the liquid outlet pipe cover plate 14 is fixed on the liquid outlet pipe 15 by bolts. superior. A liquid outlet filter device 12 is arranged in the liquid outlet pipe 15, and the liquid outlet filter device 12 is composed of a filter plate 12-1 and four support rods 12-3, and a plurality of filter holes 12-2 are arranged on the filter plate 12-1 , the support rods 12-3 are evenly distributed and welded on the filter plate 12-1, and the entire outlet filter device 12 is located on the cover plate 14 of the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com