Sand-based flat membrane-bioreactor

A bioreactor, bioreactor technology, applied in sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc. The problem of high water consumption can achieve the effect of large circulating water volume, reducing equipment costs, reducing water consumption and chemical cleaning dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

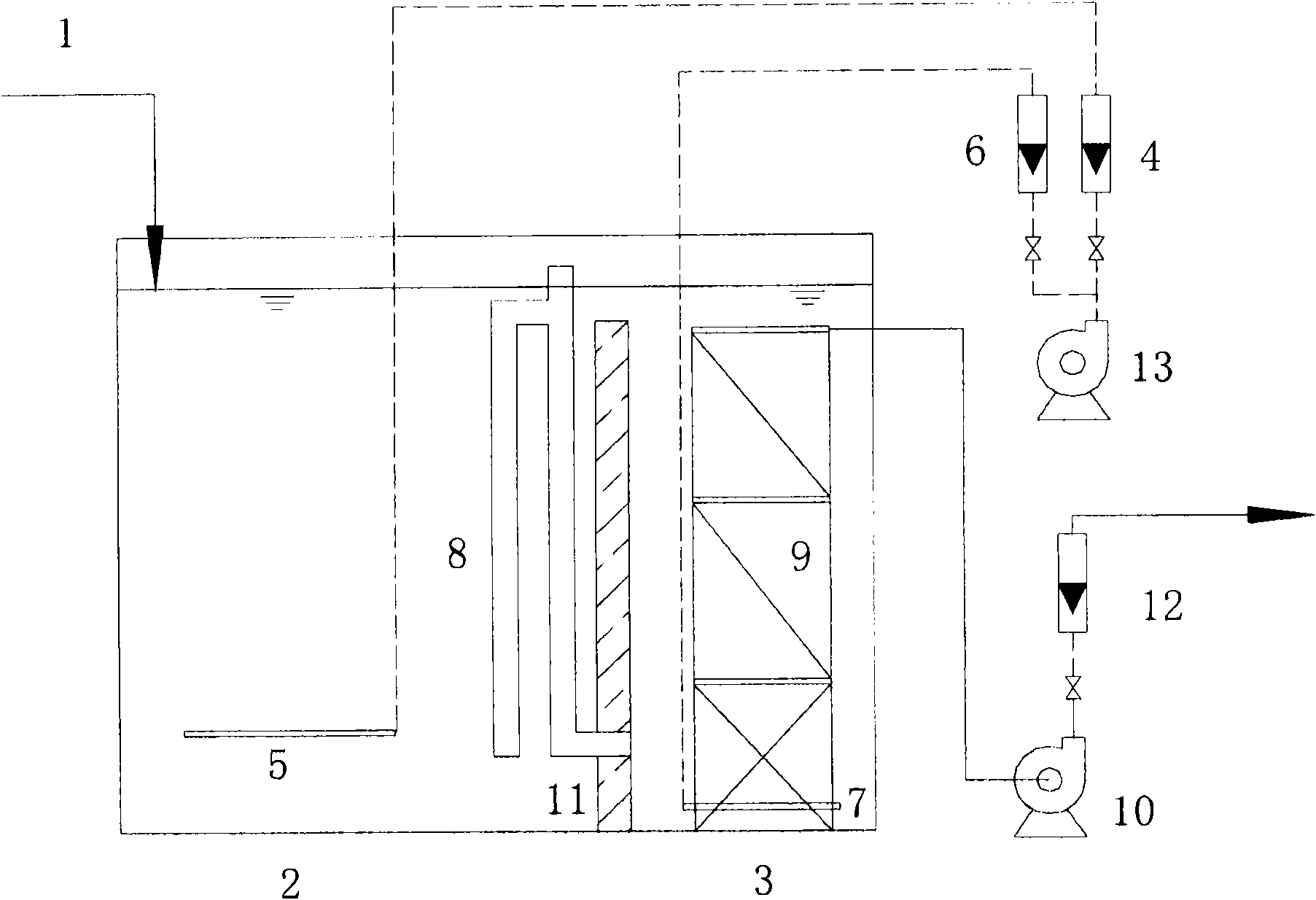

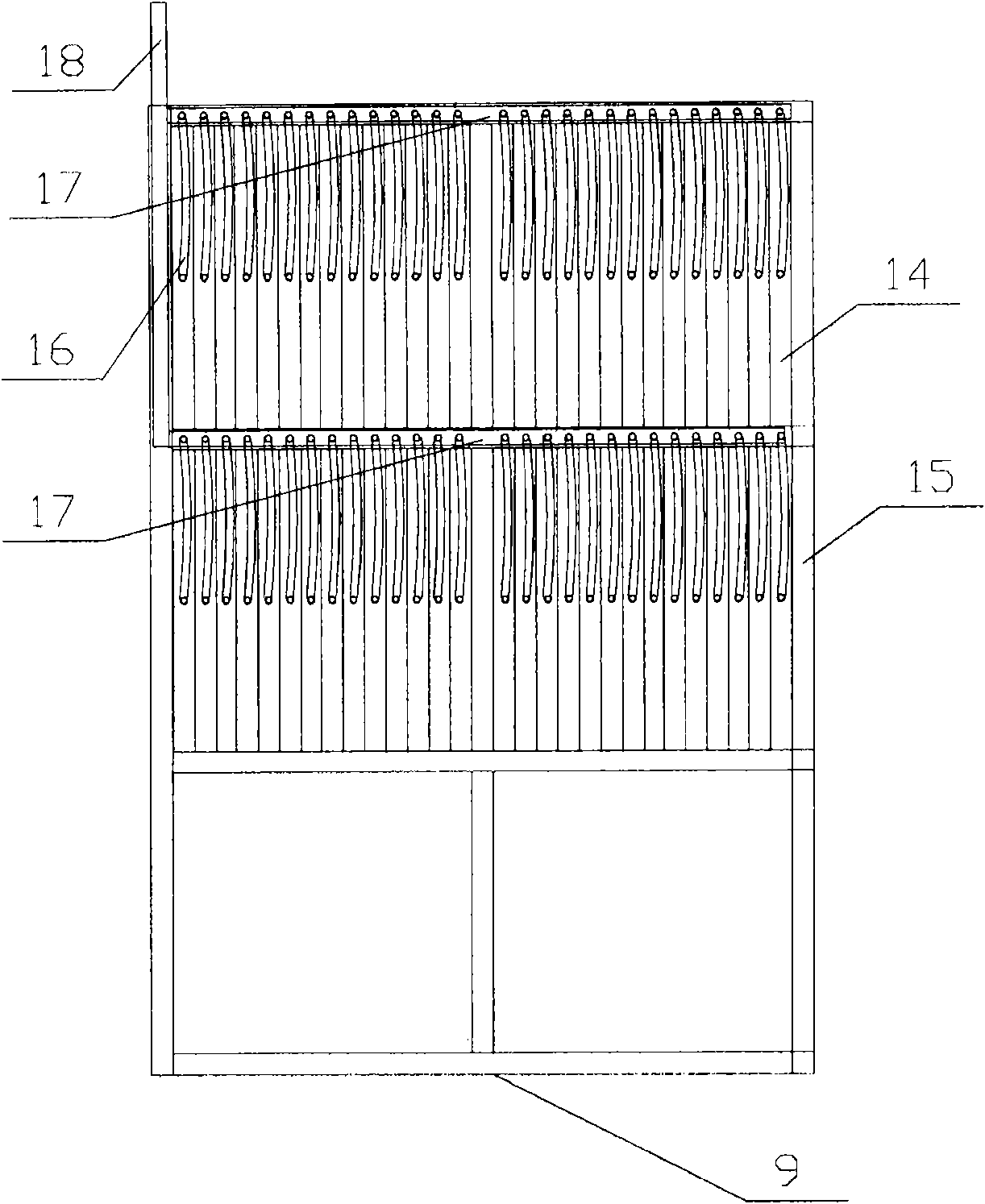

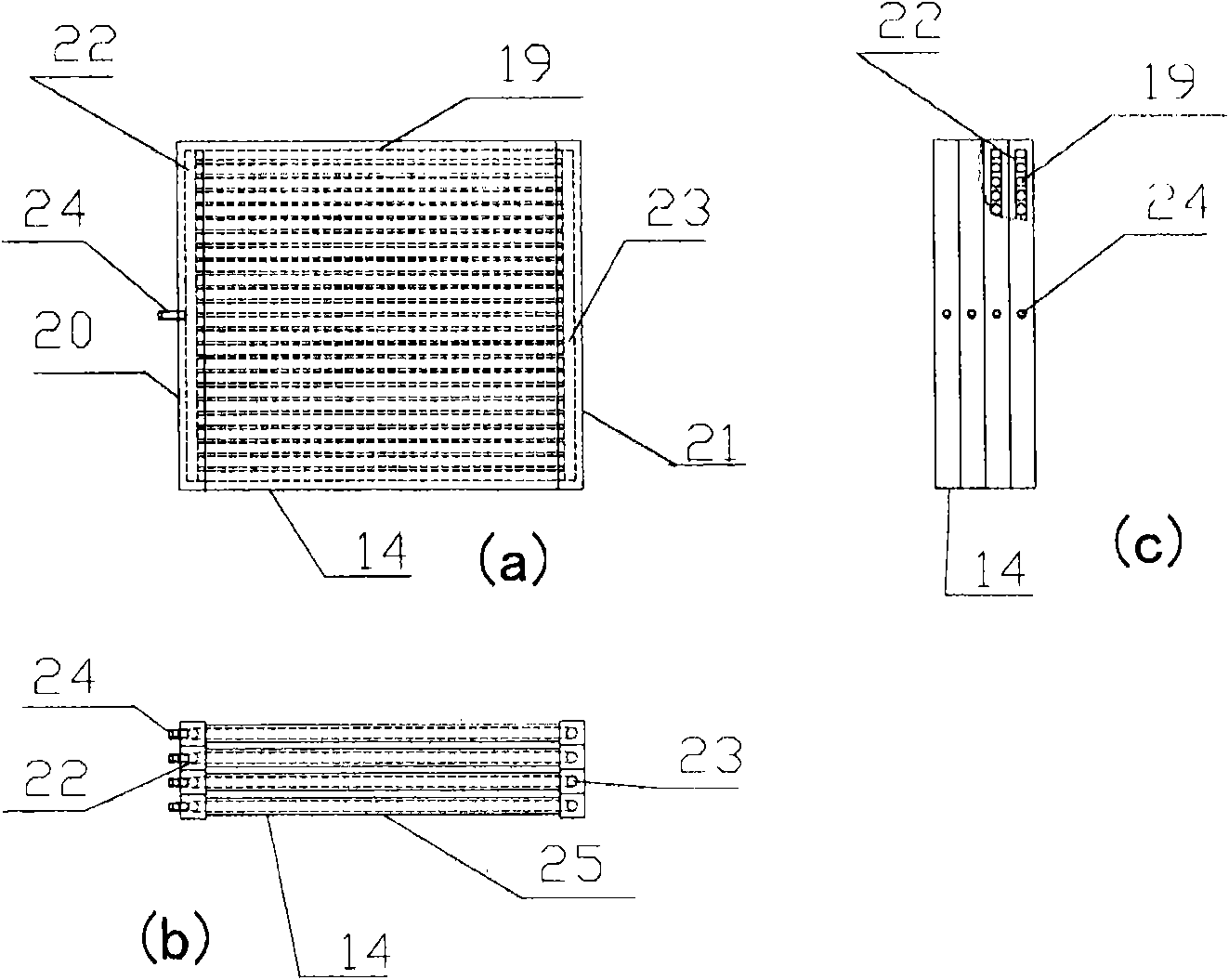

[0042] Sand-based membrane bioreactor of the present invention, it mainly comprises:

[0043] Biological reaction tank 2, membrane filter 3, biological drum air flow meter 4, biological drum air tube 5, membrane drum air flow meter 6, membrane drum air tube 7, n-shaped circulation pipe 8, sand substrate type membrane module 9, suction pump 10. Partition wall 11, purified water flow meter 12, air pump 13, sand substrate type membrane element 14, membrane support 15 (see figure 1 ).

[0044] The specific composition is: the membrane filter 3 and the biological reaction tank 2 are separated by a partition wall 11, and the top of the partition wall 11 is submerged in the biological reaction tank 2 or the membrane filter tank 3 from the water level to a depth of 10-35 cm, and the bottom of the partition wall 11 has holes An n-shaped circulation pipe 8 is installed on the partition wall 11 between the membrane filter tank and the biological reaction tank; the main body of the n-sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com