Unsymmetrical chlorine-containing polymer-based charged type hollow fiber filtration membrane and preparation method thereof

A fiber filter membrane and polymer technology, applied in the field of asymmetric chlorine-containing polymer-based charged hollow fiber filter membrane and its preparation, can solve the problems of rapid performance attenuation, performance degradation, etc., achieve stability, not easy to be damaged, reduce The effect of raw material cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

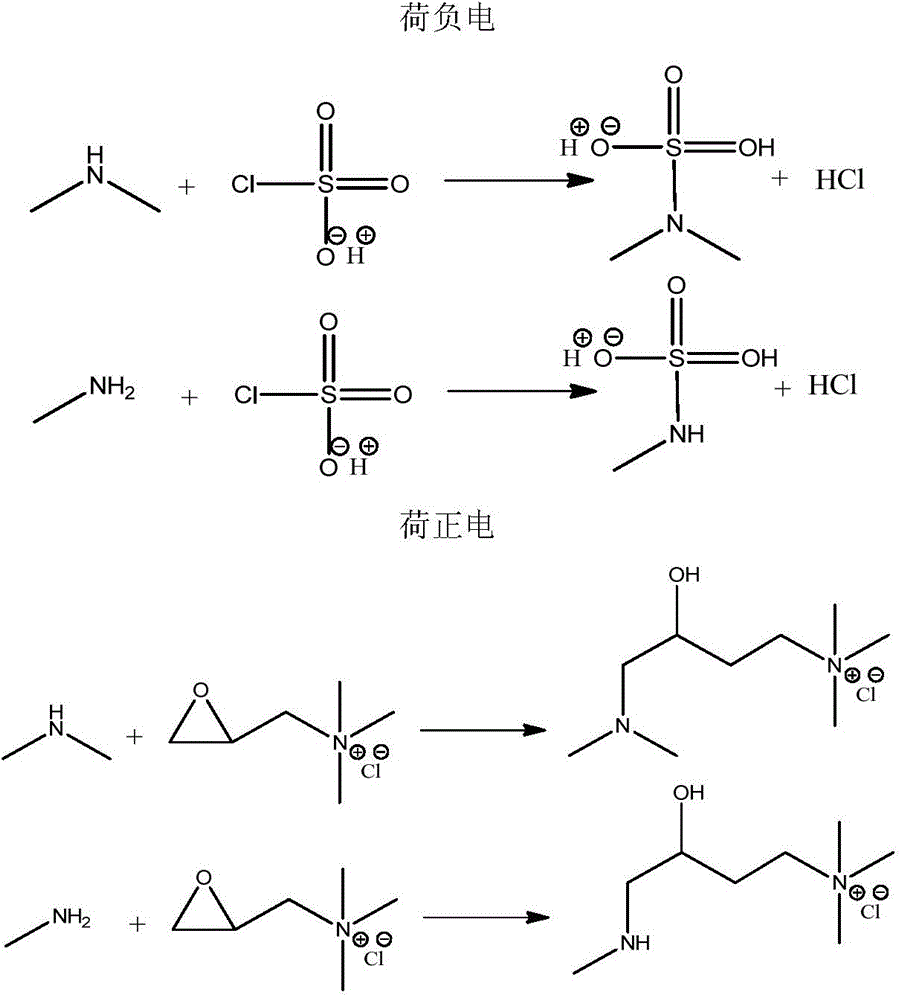

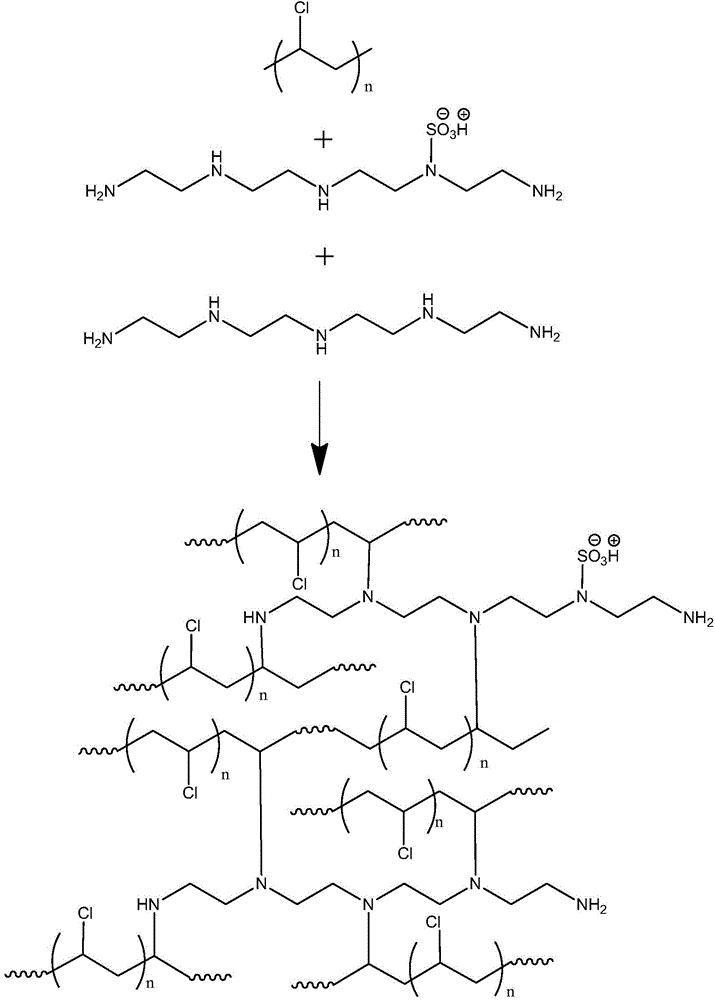

Method used

Image

Examples

preparation example Construction

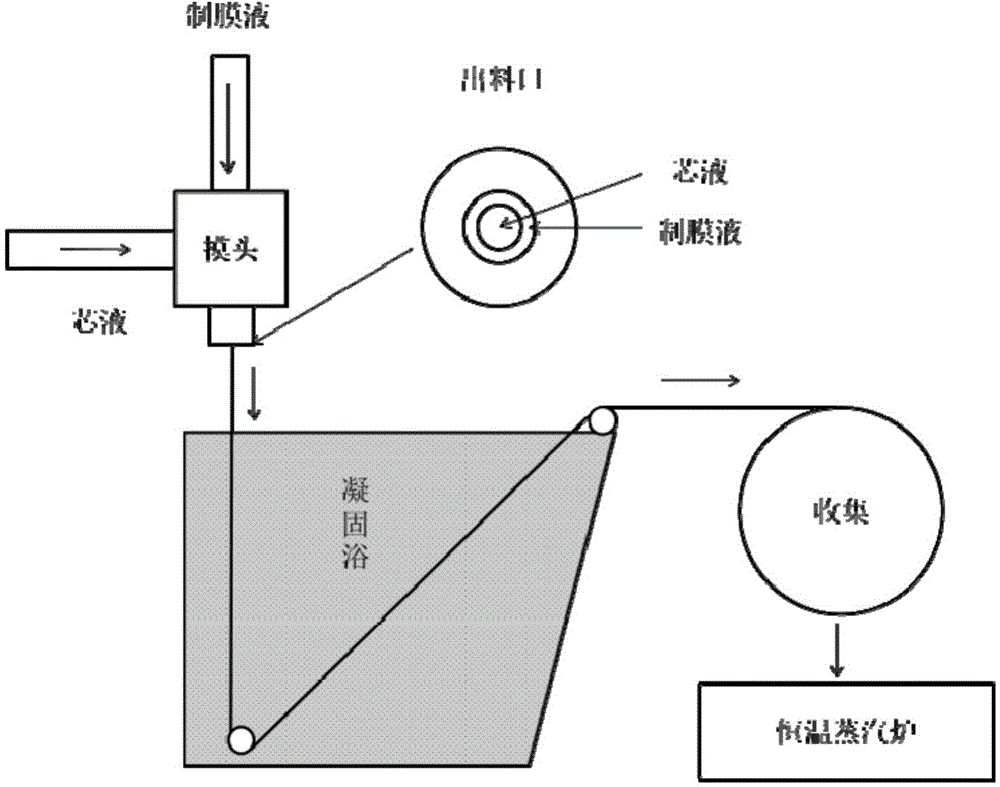

[0048] A preparation method of an asymmetric chlorine-containing polymer-based charged hollow fiber filter membrane, wherein the preparation method of the internal pressure filter membrane comprises the following steps:

[0049] (1) Dissolving the chlorine-containing polymer to make a film-making solution, using the solution of polyamines as the core solution, and using the solution containing the porogen as the coagulation bath;

[0050] (2) The core liquid is passed into the center of the die, and the membrane-making liquid is extruded from the circular channel to form a tubular liquid film, which enters the coagulation bath vertically to solidify into a hollow fiber membrane;

[0051] (3) After heat-treating the hollow fiber membrane prepared in the step (2), washing is performed to obtain a charged hollow fiber filter membrane with an asymmetric chlorine-containing polymer matrix.

[0052] The preparation method of external pressure filter membrane comprises the following ...

Embodiment 1

[0064]Dissolve 20% polyvinyl chloride in N,N-dimethylacetamide to prepare a film-making solution, and blend the reaction product of tetraethylenepentamine and epoxy quaternary ammonium salt with tetraethylenepentamine in a composition of 1:1 80% aqueous solution is then configured as the core liquid, and the aqueous solution containing 4% polyvinyl alcohol is used as the coagulation bath. The membrane was heat-treated in a saturated water vapor environment at 65°C for 8 hours, soaked and washed for 24 hours, and a positively charged internal pressure hollow fiber nanofiltration membrane was obtained. The membrane manufacturing process and process are as follows: image 3 , Figure 4 shown.

[0065] The membrane prepared above was packaged into an internal pressure cross-flow filtration module. Under 0.3MPa, the recovery ratio was 15% to test its pure water flux and the rejection rate of 0.01% positively charged dye Victoria blue B solution and 0.2 % rejection of calcium chlo...

Embodiment 2

[0068] Dissolve 18% polyvinylidene chloride in N,N-dimethylformamide to prepare a film-making solution, and use the reaction product of ethylenediamine and epoxy quaternary ammonium salt and ethylenediamine as a 2:1 blend , and then configured into an 80% aqueous solution as the core liquid, and an alcohol solution containing 1% polyvinyl alcohol as a coagulation bath. Then heat-treat the membrane in a saturated water vapor environment at 50° C. for 20 hours, soak and wash for 24 hours, and obtain a positively charged internal pressure hollow fiber nanofiltration membrane.

[0069] The membrane prepared above was packaged into an internal pressure cross-flow filtration module. Under 0.3MPa, the recovery ratio was 15% to test its pure water flux and the rejection rate of 0.01% positively charged dye Victoria blue B solution and 0.2 % rejection of calcium chloride solution. Test results, the pure water flux is 92.8L / h m 2 , the retention rate of Victoria blue B solution was 98...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com