Organic-inorganic composite nanoparticle super-hydrophilic modified polymer film and preparation method therefor

A polymer membrane and inorganic composite technology, applied in the field of membrane separation, can solve the problems of uncontrollable SiO2 particle size and uniformity, hydrophilic performance limitation, etc., to achieve the effect of reducing water penetration resistance and improving anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Step ⑴. With 12% of polyvinylidene fluoride, 9% of PEG200, 2% of methyl orthosilicate, 0.01% of No. KH550 silane coupling agent, 0.1% of acetic acid, organosilicon hydrophilic modifier A (structural formula I, R is Methyl, n=1) 0.5%, N,N-dimethylformamide 76.49% was added to the container, stirred and dissolved, and stirred at 40°C for 8 hours to obtain a uniformly stirred casting solution;

[0063] Step ⑵. Put the uniformly stirred casting solution at 40°C for 12 hours to defoam;

[0064] Step ⑶. The air bath through which the defoamed casting solution passes is 0cm, and spinning is carried out at 500kPa. The outer gel solution is water and the temperature is 35°C. The core liquid is water and the temperature is 30°C. Wet spinning produces spun fibers.

[0065] Step ⑷. Rinse in pure water for 24 hours, take it out and dry it in the air to prepare an organic-inorganic composite nanoparticle superhydrophilic modified polymer film.

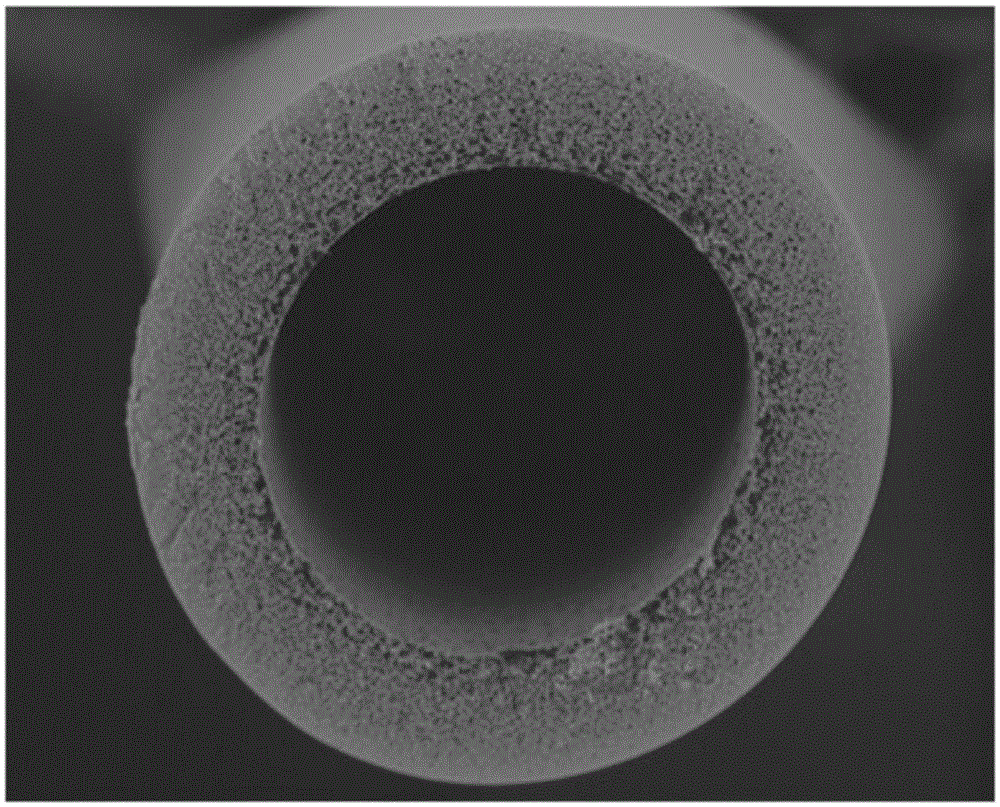

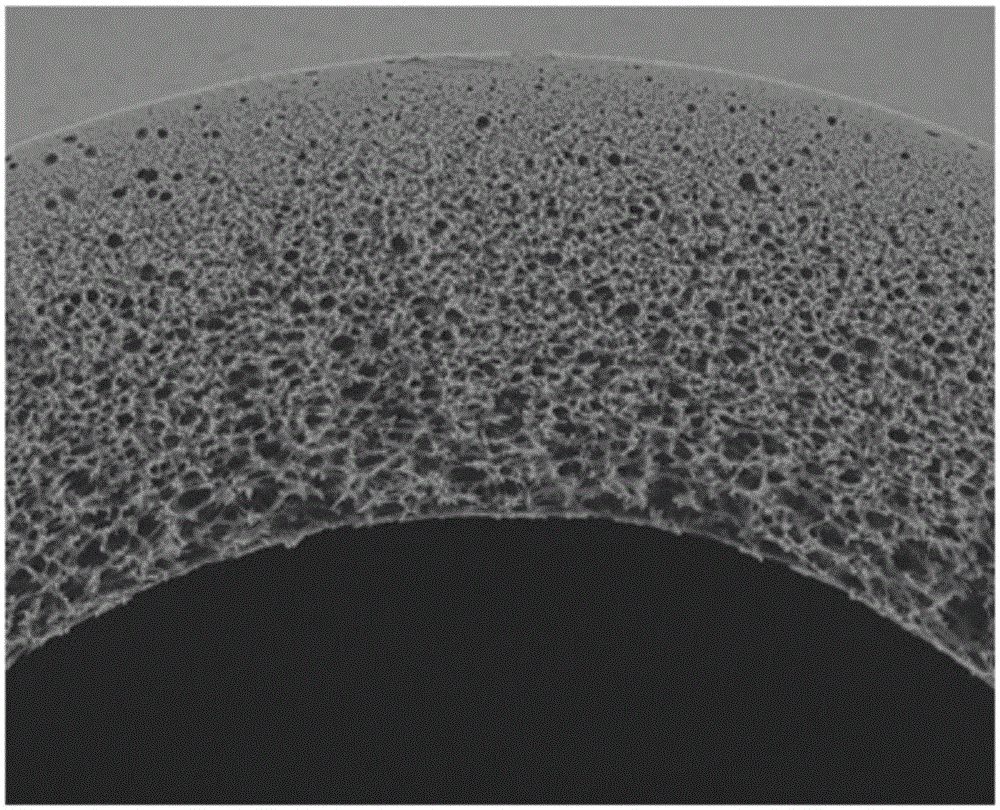

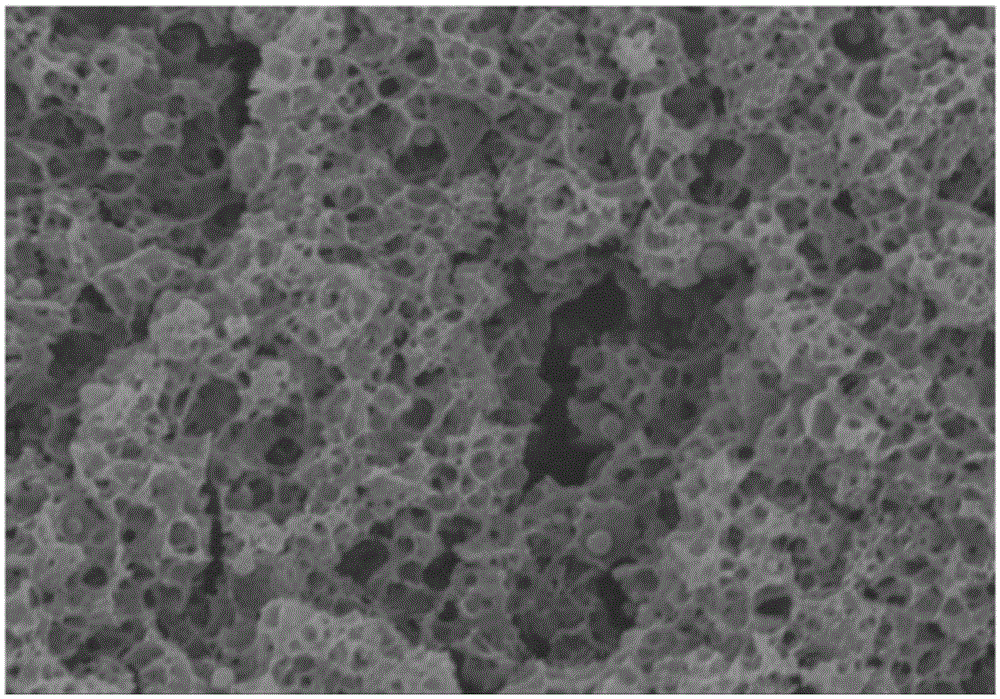

[0066]The porosity of the finally ob...

Embodiment 2

[0068] Step ⑴. Polysulfone 15.5%, PEG6002%, tetraethyl orthosilicate 8%, No. KH560 silane coupling agent 0.3%, oxalic acid 0.2%, organosilicon hydrophilic modifier B (structural formula Ⅰ, R is ethyl, n=10) 1.5%, N,N-dimethylacetamide 72.5% were added to the container, stirred and dissolved, and stirred at 55°C for 14 hours to obtain a uniformly stirred casting solution;

[0069] Step ⑵. Put the uniformly stirred casting solution at 55°C for 15 hours to defoam;

[0070] Step ⑶. The air bath through which the defoamed casting solution passes is 2cm, and spinning is carried out at 700kPa. The outer gel solution is a mixture of N,N-dimethylacetamide and water, and the mixing ratio is 1:2 , the temperature is 38°C, the core liquid is a mixture of N,N-dimethylacetamide and water, the mixing ratio is 1:2 and the temperature is 35°C, and the primary fiber is obtained by dry-wet spinning.

[0071] Step ⑷. Rinse in pure water for 36 hours, take it out and dry it in the air to prepare ...

Embodiment 3

[0074] Step (1) with polyethersulfone 15%, PEG800 3%, tetrabutyl orthosilicate 10%, No. KH570 silane coupling agent 0.9%, benzoic acid 0.3%, organosilicon hydrophilic modifier C (structural formula II, R For methyl, n=30) 2%, N-methylpyrrolidone 68.8% was added to the container, stirred and dissolved, and stirred at 60°C for 17 hours to obtain a uniformly stirred casting solution;

[0075] Step ⑵. Put the uniformly stirred casting solution at 60°C for 17 hours to defoam;

[0076] Step (3). The air bath through which the defoamed casting liquid passes is 3 cm, and spinning is carried out at 1.3 MPa. The outer gel liquid is a mixture of N-methylpyrrolidone and water, the mixing ratio is 3:4, and the temperature is 40°C, the core liquid is a mixture of N-methylpyrrolidone and water, the mixing ratio is 3:5, the temperature is 40°C, and the primary fiber is obtained by dry-wet spinning.

[0077] Step ⑷. Rinse in pure water for 36 hours, take it out and dry it in the air to prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com