Antiseptic fragrant paper towel and manufacturing method thereof

A technology of paper towels and fragrance, applied in the direction of paper, enhancer addition, plant raw materials, etc., can solve the problems of high cost of disinfectant wipes or towels, sterilization and disinfection of hand surfaces, and long drying time, so as to reduce the formation of scars , long-lasting antibacterial effect, simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

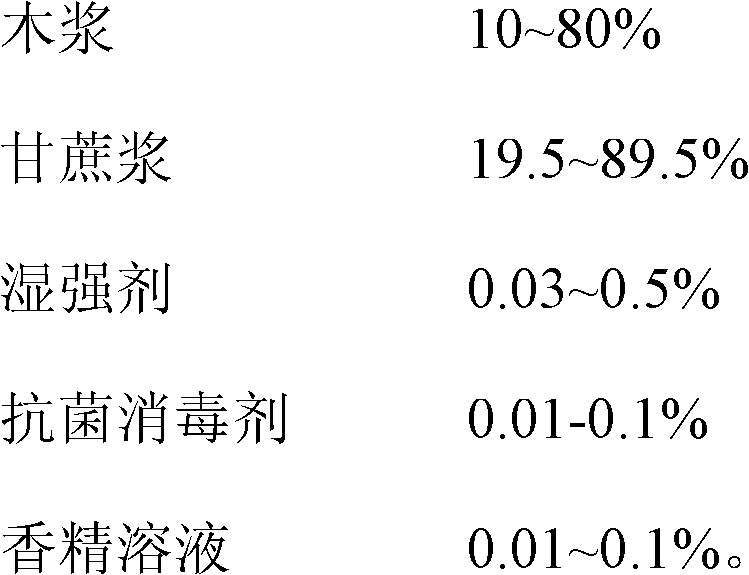

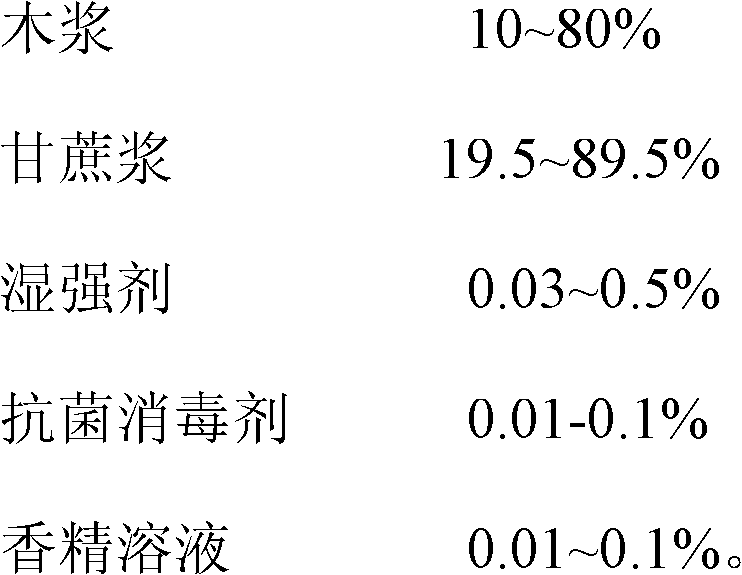

Embodiment 1

[0051] Wood pulp 34.84%, sugarcane pulp 65%, wet strength agent 0.1%,

[0052] Antibacterial disinfectant 0.03% (8% sodium silver solution), essence solution 0.03% (7% essence solution).

[0053] Manufacturing method:

[0054] a. Mix wood pulp and sugarcane pulp, refine pulp, add wet strength agent, and dilute with water.

[0055] b. The slurry obtained in step a is formed by a headbox and a mesh cloth, and then vacuum dehydrated, pressed to form a dryness of 35%, and then sprayed with an antibacterial disinfectant and an essence solution.

[0056] c. Put the molded paper pulp prepared in step b into a drying cylinder and dry at 105 degrees to obtain antibacterial, disinfected and fragrant paper towels.

Embodiment 2

[0058] 49.7% wood pulp, 50% sugarcane pulp, 0.2% wet strength agent,

[0059] Antibacterial disinfectant 0.05% (6% sodium silver solution), essence solution 0.05% (5% essence solution).

[0060] Manufacturing method:

[0061] a. Mix wood pulp and sugarcane pulp, refine pulp, add wet strength agent, and dilute with water.

[0062] b. The slurry obtained in step a is formed by a headbox and a mesh cloth, then vacuum dehydrated, pressed to form a dryness of 40%, and then sprayed with an antibacterial disinfectant and an essence solution.

[0063] c. Put the molded paper pulp prepared in step b into a drying cylinder and dry at 105 degrees to obtain antibacterial, disinfected and fragrant paper towels.

Embodiment 3

[0065] Wood pulp 59.6%, sugar cane pulp 40%, wet strength agent 0.3%,

[0066]Antibacterial disinfectant 0.07% (4% sodium silver solution), essence solution 0.03% (8% essence solution).

[0067] Manufacturing method:

[0068] a. Mix wood pulp and sugarcane pulp, refine pulp, add wet strength agent, and dilute with water.

[0069] b. The slurry prepared in step a is formed by a headbox and a mesh cloth, then vacuum dehydrated, pressed to form a dryness of 45%, and then sprayed with an antibacterial disinfectant and an essence solution.

[0070] c. Put the molded paper pulp prepared in step b into a drying cylinder and dry at 105 degrees to obtain antibacterial, disinfected and fragrant paper towels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com