Cylinder head drain and vent

A cylinder head, channel technology, applied in the field of drainage and ventilation, can solve the problems of insufficient oil cooling, restricting ventilation and oil drainage, increasing the possibility of oil coking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

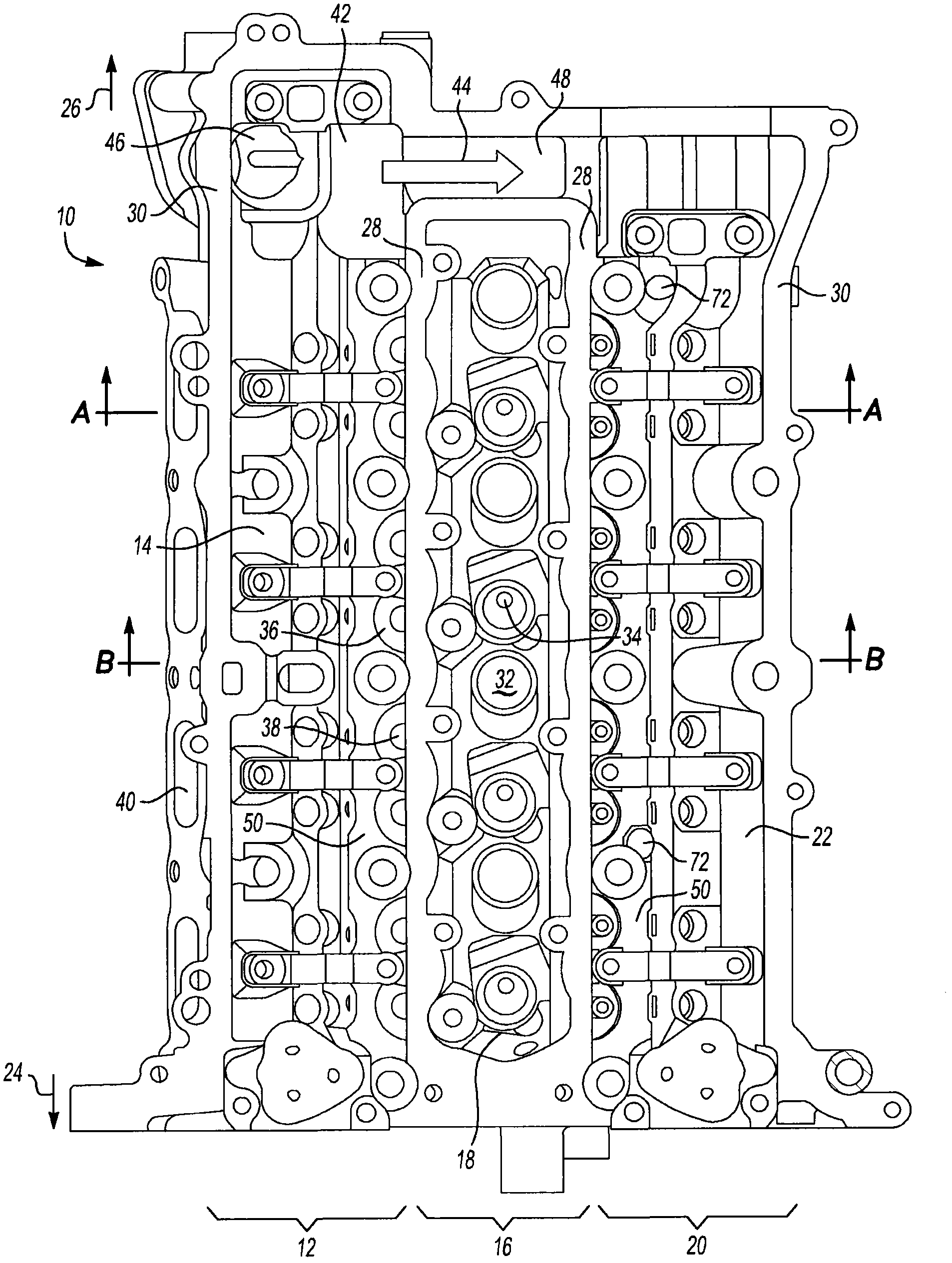

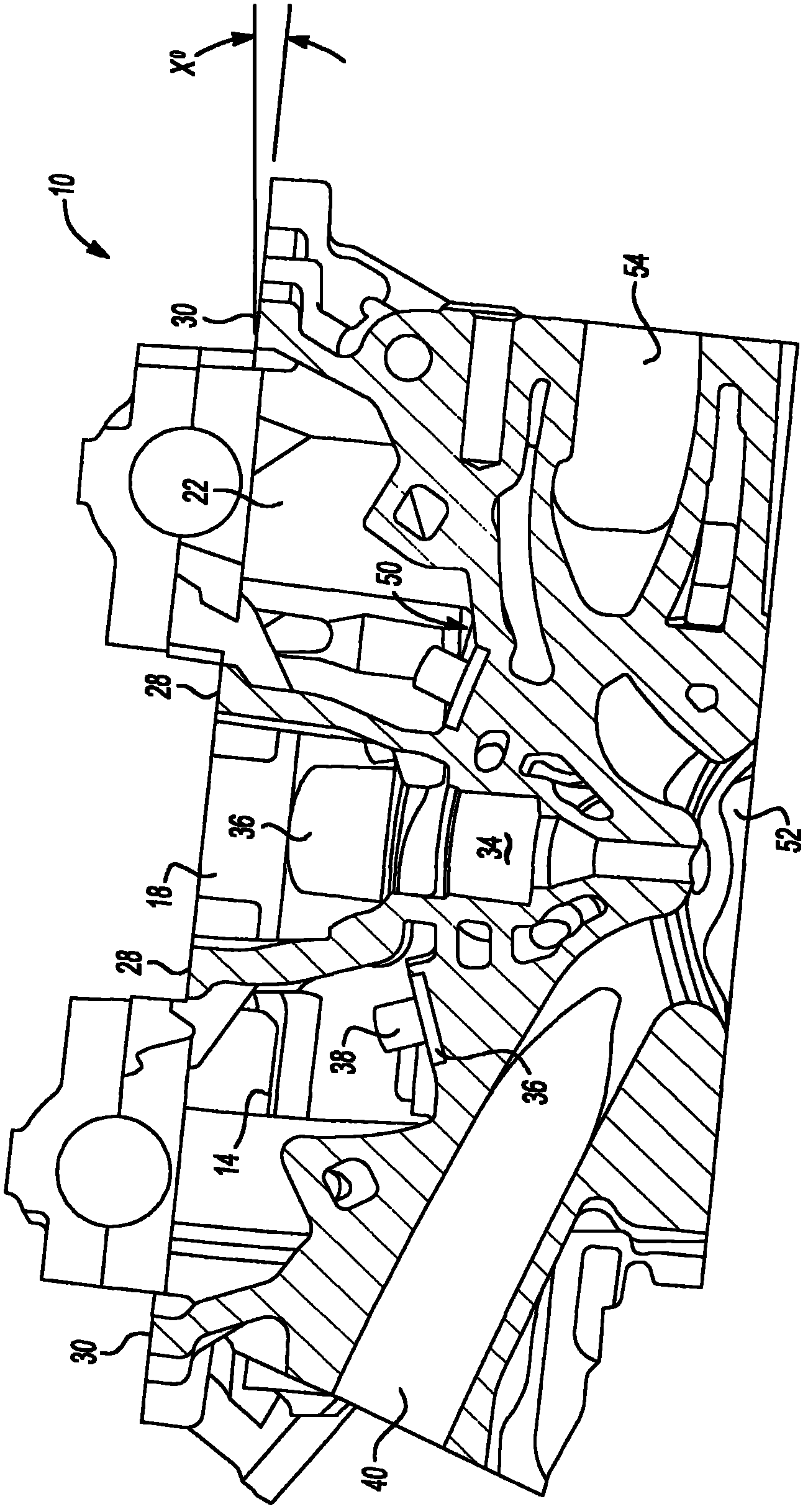

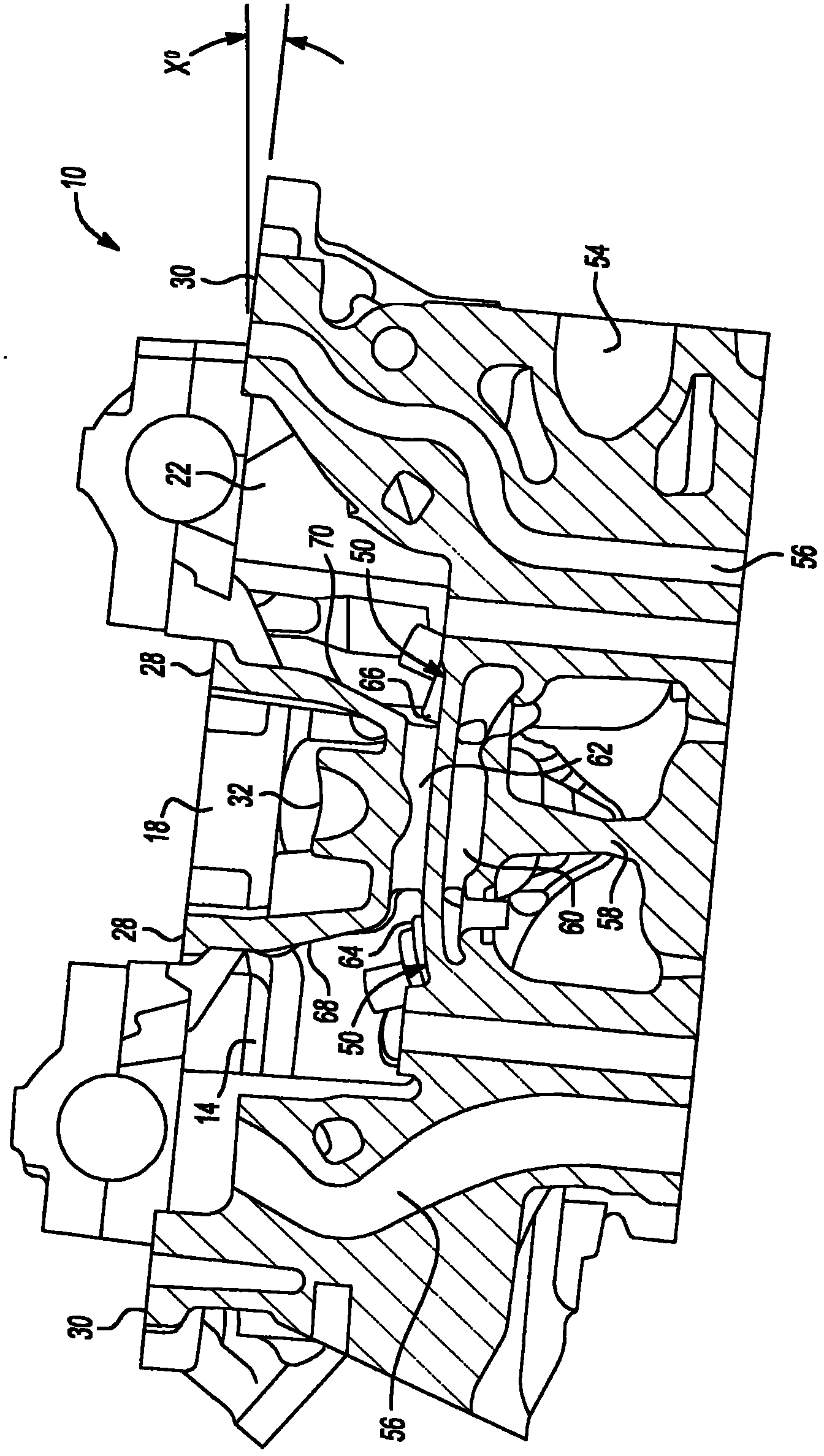

[0056] Referring to the drawings, wherein like reference numerals designate like parts throughout the several views, and from figure 1Initially, a schematic top view of a partially assembled cylinder head is indicated generally at 10 . Cylinder head 10 is typically formed as a casting of aluminum or cast iron and may be otherwise finished by machining, grinding, or other processes. Cylinder head 10 (which may also be referred to as head 10 ) is configured to include a first side 12 and a second side 20 extending from a front portion of head 10 generally along a longitudinal axis of head 10 . 24 to a rear portion 26 and are separated by a central portion 16 . The first chamber 14 is defined by the first side 12 of the cover 10 and the second chamber 22 is defined by the second side 20 of the cover 10 .

[0057] Central portion 16 defines a valley 18 extending generally along the longitudinal axis of the cylinder head and generally separating chamber 14 from chamber 22 . Disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com