Welding structure of rotary type compressor pump body and rotary type compressor pump body provided therewith

A technology of rotary compressor and welding structure, applied in the direction of rotary piston/swing piston pump, parts of pumping device for elastic fluid, machine/engine, etc. Increase costs and other issues to achieve the effect of reducing fit, improving welding deformation, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

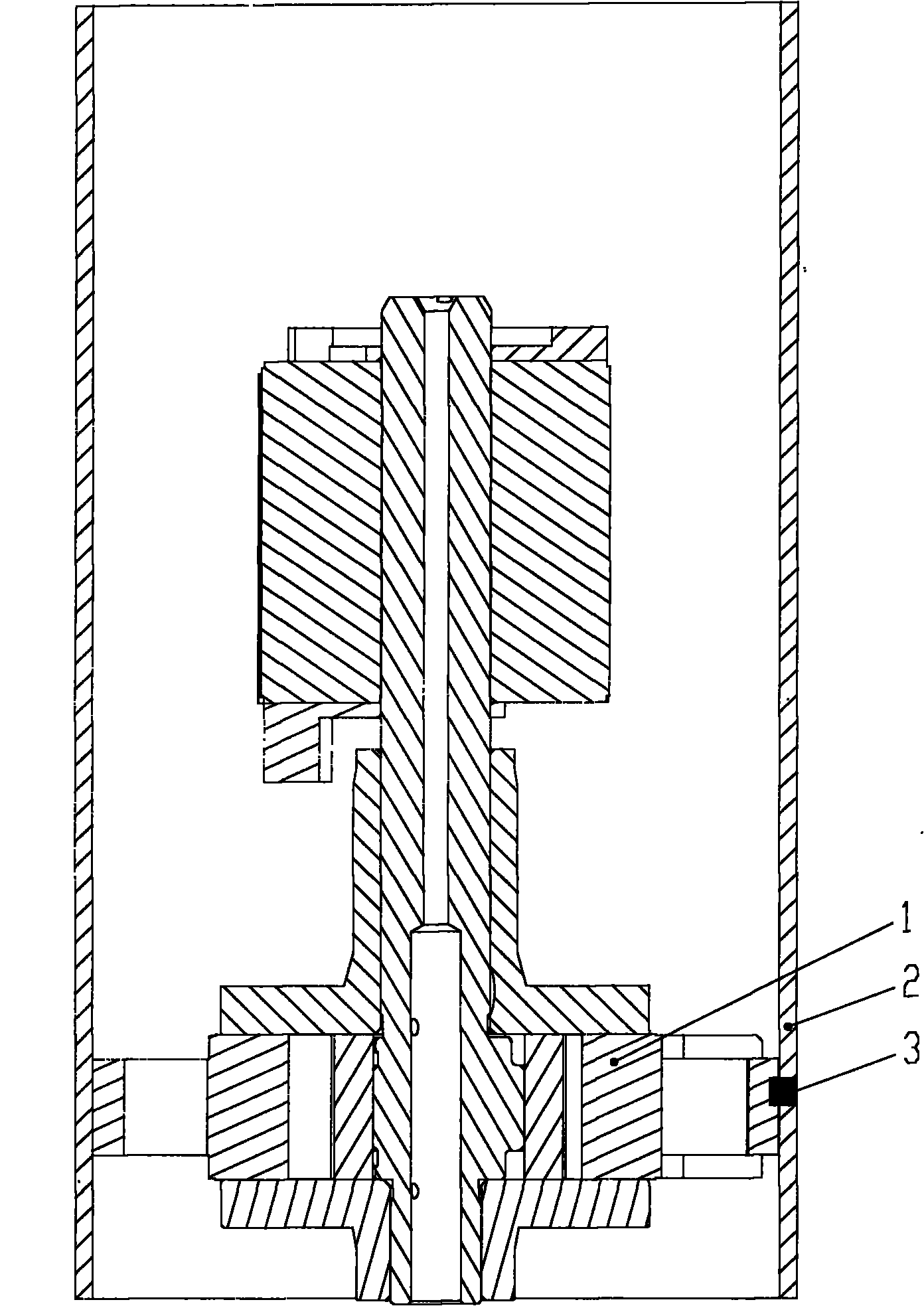

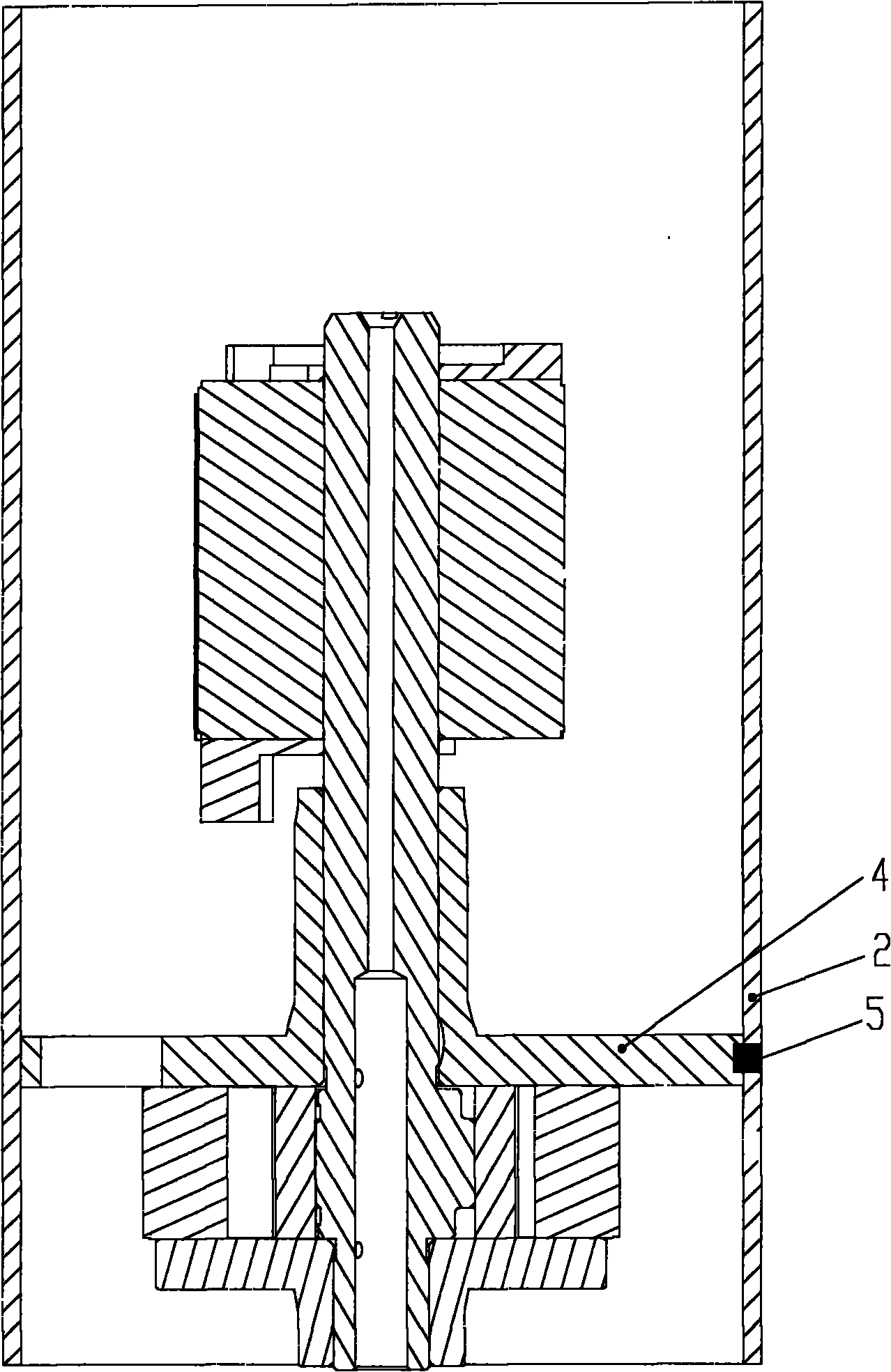

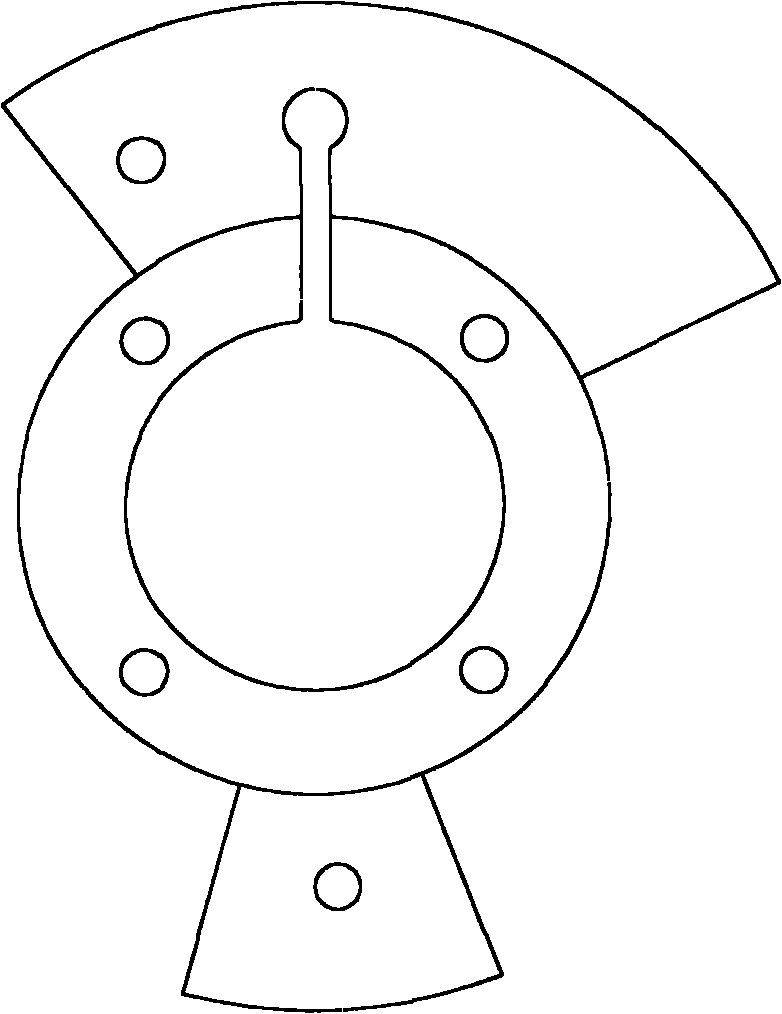

[0023] see Figure 5 The welded structure of the pump body of the rotary compressor of the present invention includes a cylinder 10 and a casing 20. The outer circle 14 of the cylinder 10 is provided with a welded structure, and the pump body is fixed to the casing 20 by welding. refer to Image 6 As shown, a protruding welding seat 13 is provided on the outer circle 14 of the cylinder 10, recesses 12 are provided on both sides of the welding seat 13, and a welding hole 11 is provided on the welding seat 13. This structure changes the transfer path of welding heat and the load-bearing form of the fixing part, reduce the contact area between the cylinder 10 and the housing 20, weaken the deformation of the housing 20 after welding to squeeze the cylinder 10, and improve the phenomenon that the cylinder 10 is easily deformed.

[0024] The welding hole 11 is used for welding the cylinder 10 and the housing 20, the diameter A of the welding hole 11 is 2-8 mm, and the distance D b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outside width | aaaaa | aaaaa |

| Inner width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com