Synchronizer assembly

A synchronizer and assembly technology, applied to clutches, mechanically driven clutches, mechanical equipment, etc., can solve the problems of synchronizer failure, large moment of inertia, and large impact of lock pins, etc., and achieve long service life, firm structure, and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

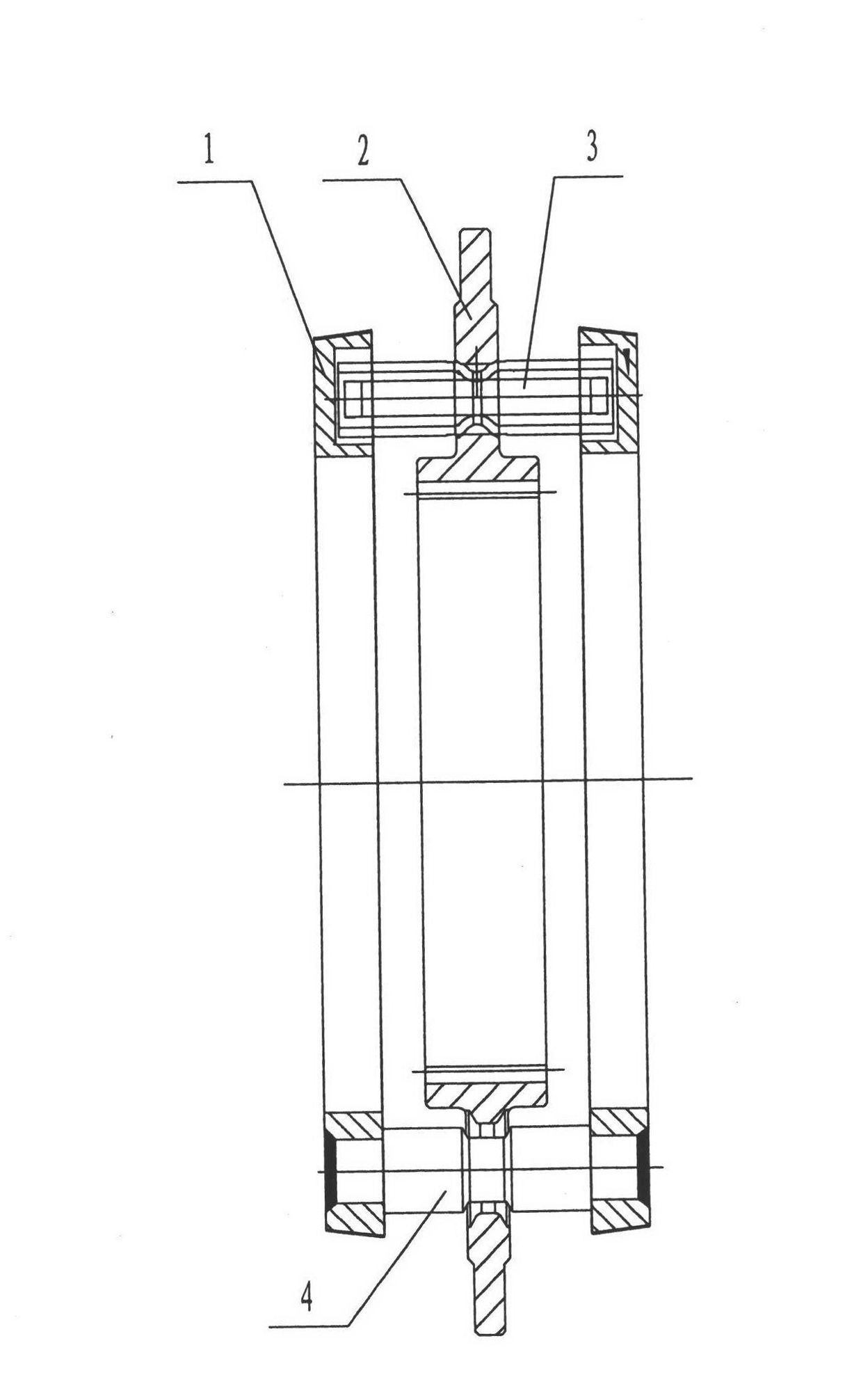

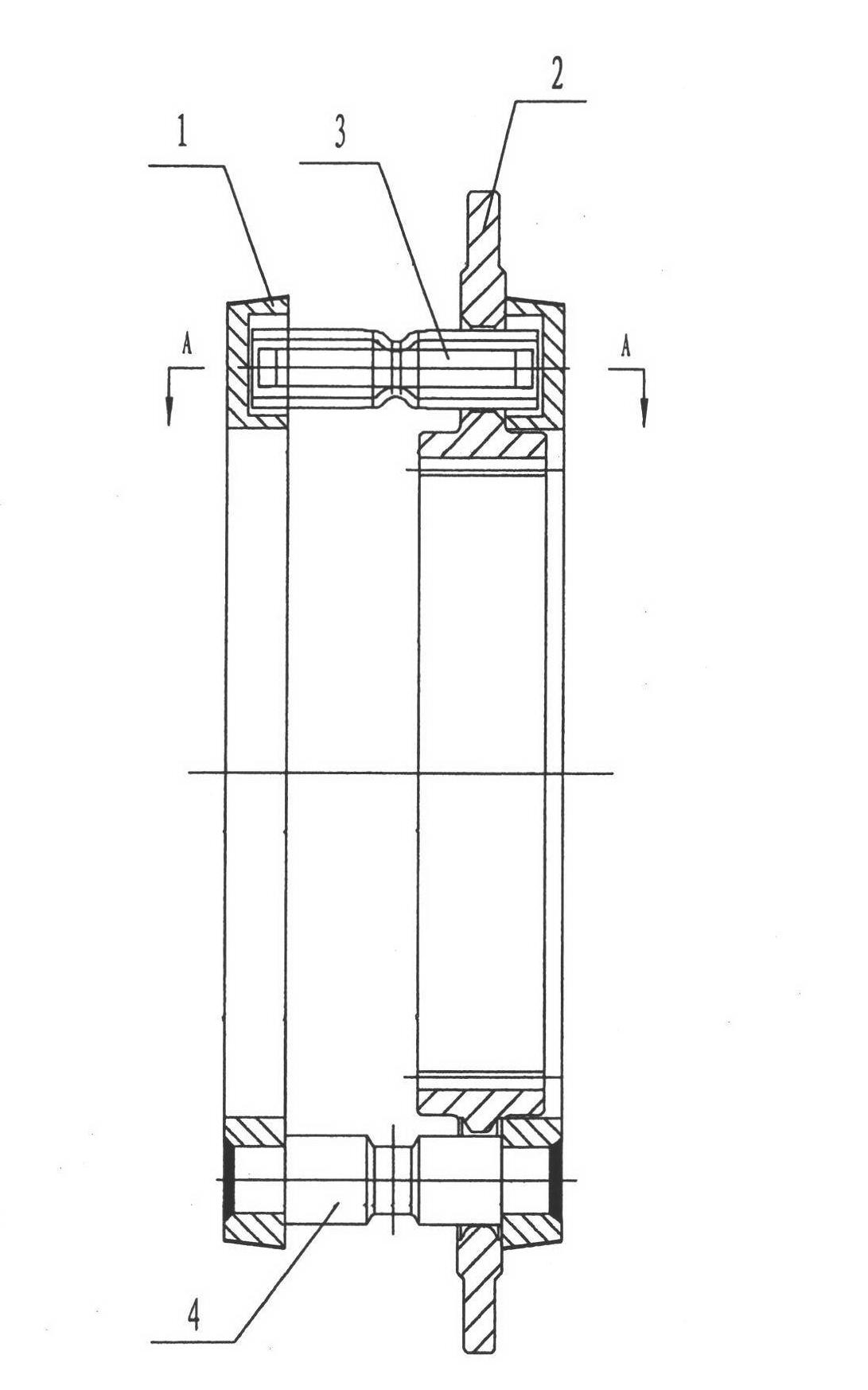

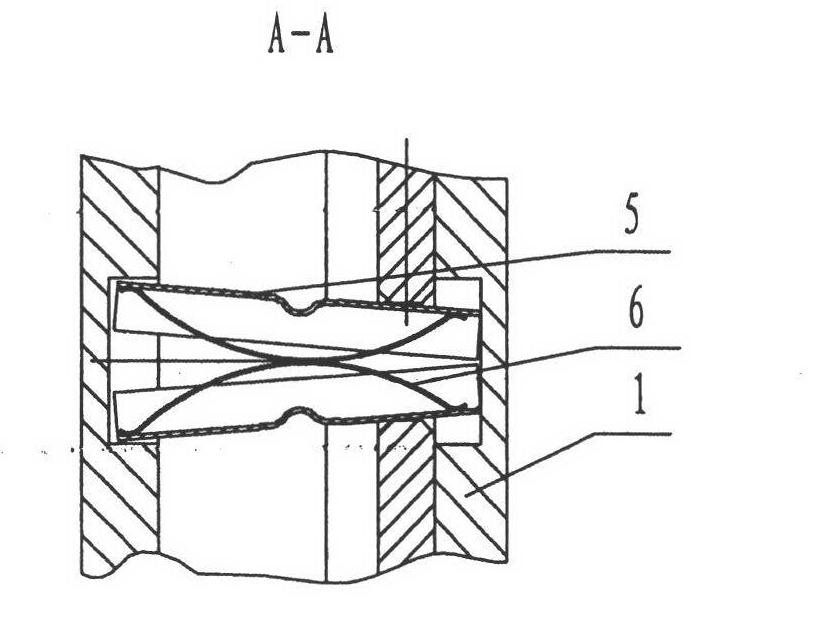

[0010] Such as figure 1 , figure 2 and image 3 As shown, the present invention is a synchronizer assembly, which includes two synchronous rings 1, a sliding tooth sleeve 2, three sets of positioning pin systems 3 and three lock pins 4, and the surface of the synchronous ring 1 is bonded with wear-resistant carbon fiber Cloth; the structure of the sliding gear sleeve 2 is different from the traditional one. There is no fork slot on the edge of the sliding gear sleeve 2, which is a fork plate structure; the positioning pin system 3 consists of two semicircular positioning pins 5 and two bow springs 6 form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com