System for monitoring boiler efficiency of thermal power station on line based on identification of calorific capacity of fire coal

A power plant boiler and monitoring system technology, applied in the field of monitoring systems, can solve problems such as unsatisfactory, boiler efficiency and actual value deviation, and achieve the effects of easy data, good versatility and robustness, and improved identification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

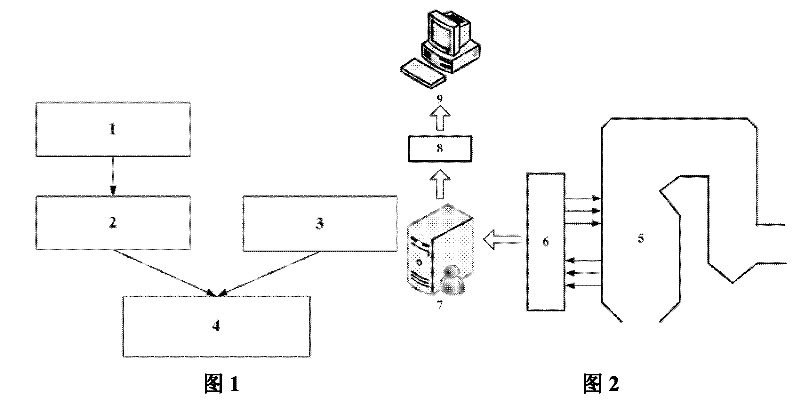

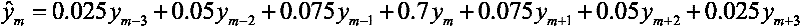

Method used

Image

Examples

Embodiment Construction

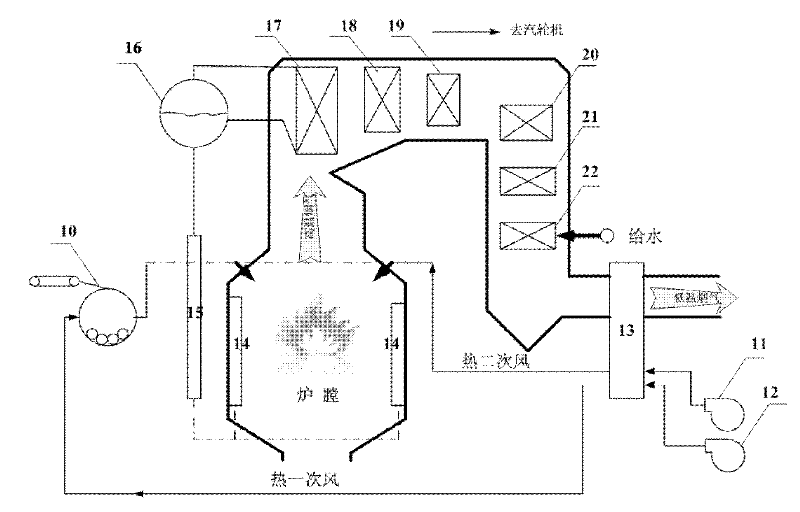

[0041] This embodiment is carried out on the premise of the technical solution of the present invention, and the detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

[0042] The boiler in this embodiment satisfies the following conditions:

[0043] 1. The boiler is HG-1025 / 17.3-WM18 type, the boiler load is 300MW, the boiler adopts subcritical, natural circulation, one intermediate reheating, double arch single furnace, "W" flame combustion mode, double flue at the tail, flue gas Baffle temperature adjustment, balanced ventilation, solid slag discharge, open-air layout, all-steel suspended drum furnace;

[0044] 2. The combustion and heat transfer processes in the furnace can be approximately considered separately;

[0045] 3. The external heat flow of the heat exchanger is evenly distributed along the tube length and circumference;

[0046] 4. The metal of the heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com