Valve seat testing device of float ball valve and testing method thereof

A floating ball valve and testing device technology, applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems of inability to obtain relevant data of valve seat deformation, complicated operation, etc., and achieve simple and effective testing methods. Easy-to-operate, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

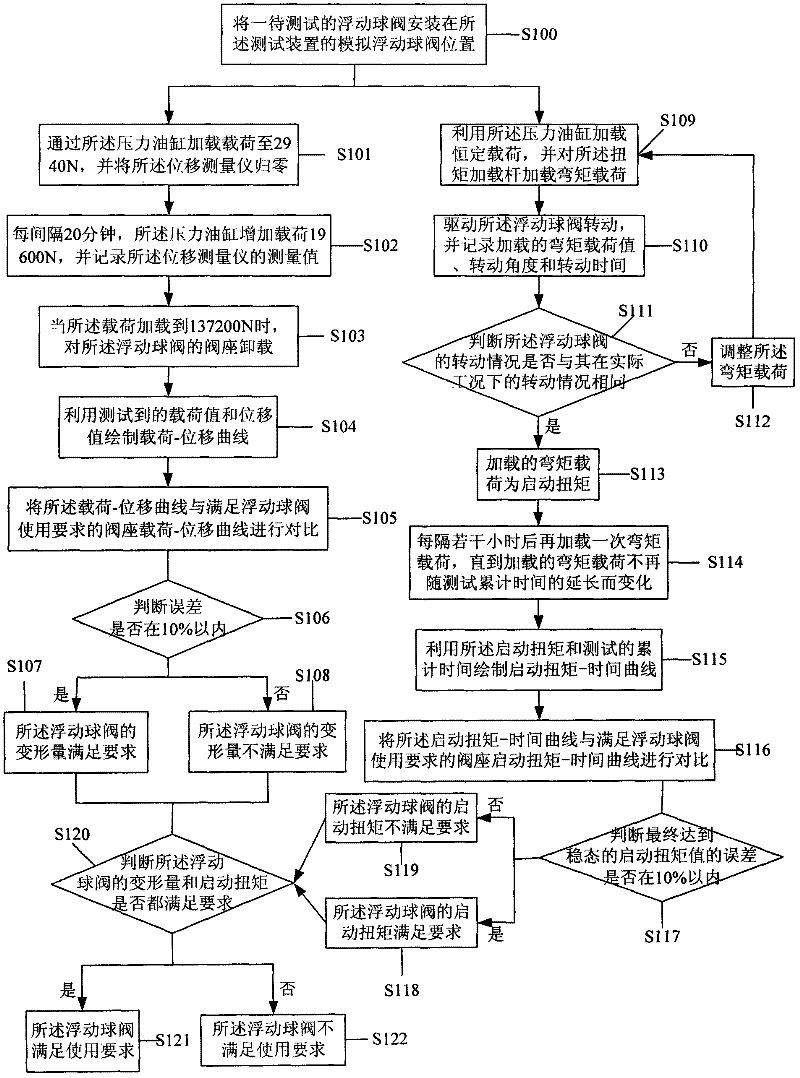

[0106] (1) Simulate the deformation of the valve seat during the assembly process of the floating ball valve

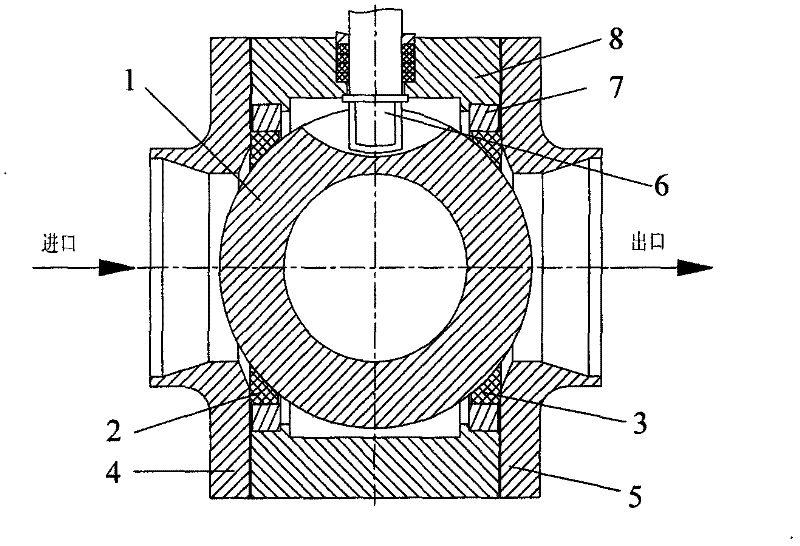

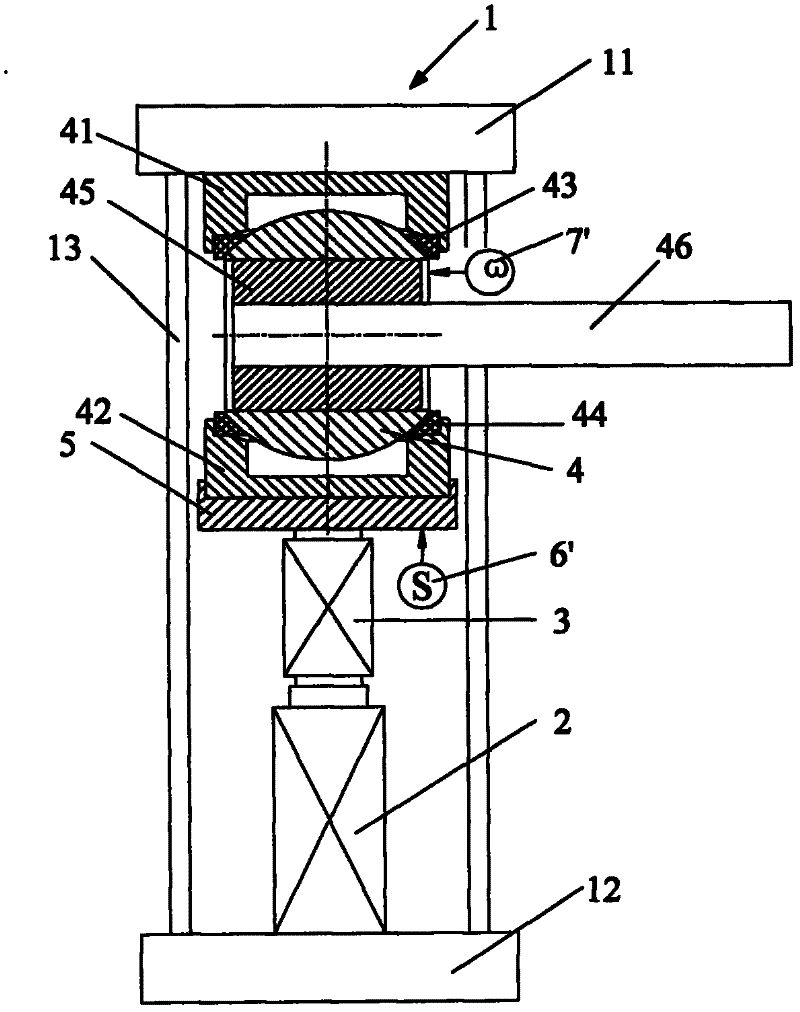

[0107] First, install the valve seat to be tested in the test device, and install the test device according to figure 2 The structure shown is installed.

[0108] Then, use the pressure cylinder to load the load to 2940N (0.3 ton force), and reset the displacement measuring instrument to zero. Every 20 minutes, increase the load by 19600N (2 ton force), and record the measured value of the displacement measuring instrument until the load reaches 137200N (14 ton force). Among them, the recorded loading load value and displacement value are shown in Table 1.

[0109] Then, use the tested load value and displacement value to draw the valve seat load-displacement curve (the curve starts from the abscissa displacement value 0mm and the ordinate loading load 0N point). Based on the seat load-displacement curve that meets the requirements of the floating ball valve, comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com