Preparation method and preparation device for lateritic cobalt and nickel ore analytical samples

A sample preparation and sample technology, which is applied in the preparation of nickel ore analysis samples and laterite-type cobalt, can solve the problems of low grade, low analysis results, unreliable analysis results, etc., and achieve safe separation of water and samples, and reliable analysis results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

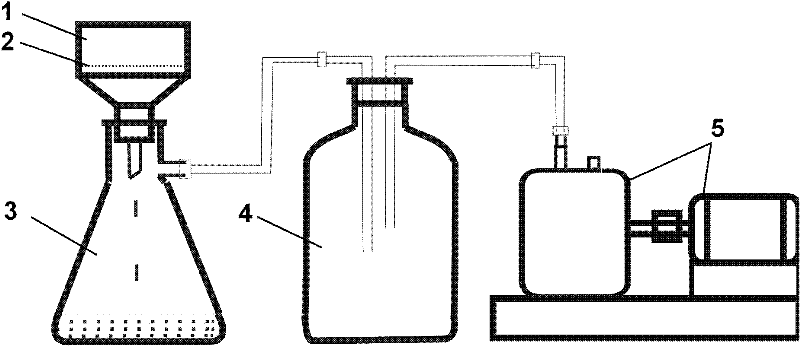

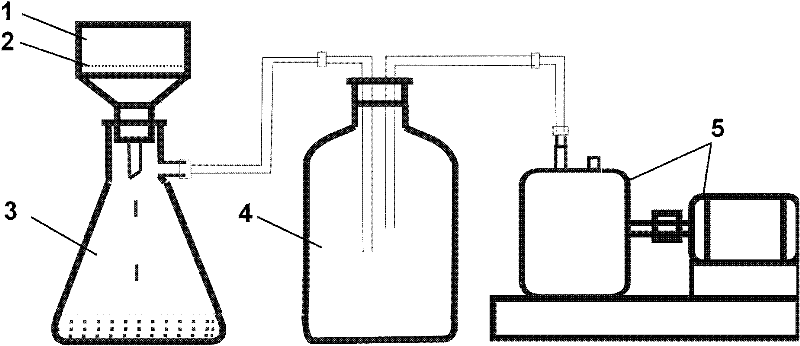

[0030] The preparation method and preparation device of a laterite-type cobalt and nickel ore analysis sample provided by the present invention will be described in detail below with reference to the accompanying drawings and examples.

[0031] A kind of preparation method of laterite type cobalt, nickel ore analysis sample, comprises the steps:

[0032] Step 1. Drying and grinding: put the laterite-type cobalt and nickel ore samples in an oven to dry, and the drying temperature should be 95°C ± 5°C to prevent damage to the crystal water in the ore samples; then place the samples on On the soft rubber board, use a wooden stick or a rubber stick to roll it thin. It should be ensured that the soil clods in the mine sample are rolled fine, but the gravel in the mine sample is not rolled fine.

[0033] Step 2, sieving and washing: Pass the thinned sample in step 1 through a 2-4mm sieve (optimum 2mm sieve), the sieved sample is reserved for No. 1 sample, and the unsifted sample is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com