Water erosion experimental facility with/under rotary impact of high-pressure water jet

A technology of high-pressure water jet and experimental device, which is applied in the direction of testing wear resistance, etc., can solve the problem of limited collision speed, and achieve the effects of increasing liquid-solid collision speed, shortening experiment time, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

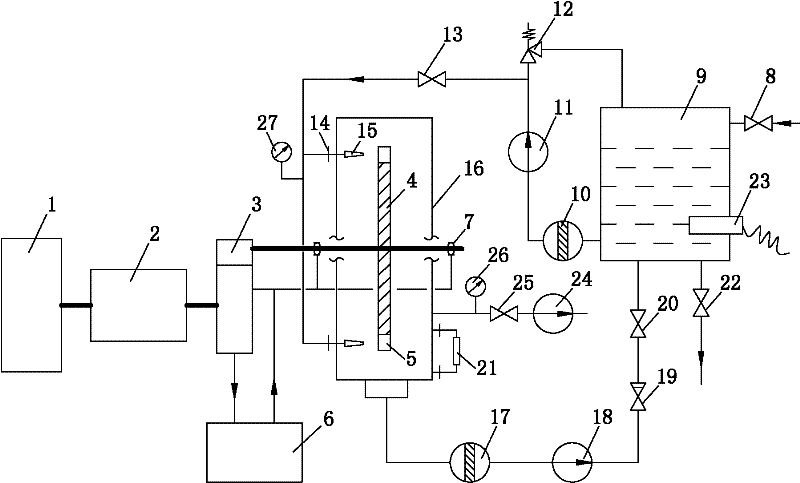

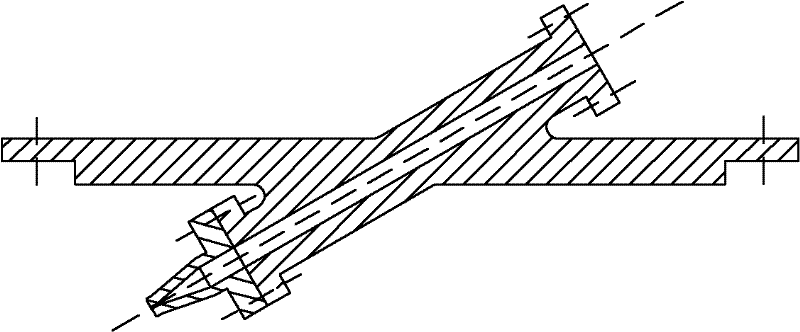

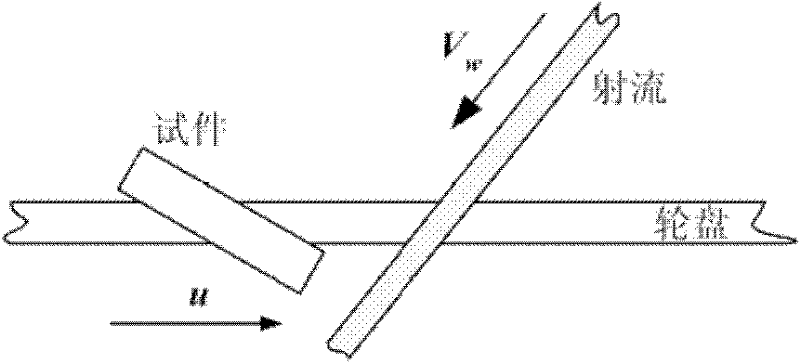

[0022] exist figure 1 Among them, the motor 2 is used as the prime mover, the motor control cabinet 1 is connected with the motor 2, and the motor control cabinet 1 precisely controls the speed, start and stop of the motor 2; the motor 2 is connected with the gearbox 3, and the rotor 4 is driven after changing the speed through the gearbox 3 Rotating, the test piece 5 is installed on the rotor 4 and drives the test piece 5 to rotate at a high speed; the closed cylinder 16 is set on the rotor 4, the rotor 4 is supported by the bearings 7 installed on both sides of the sealed cylinder 16, and the lubricating oil station 6 and The gear box 3 is connected with the bearing 7 of the rotor 4, lubricates and cools the gear box 3 and the bearing 7 to ensure its normal operation; the water tank 9 of the water circulation system is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com