Implementation method for networked system structure of numerical control system

A technology of numerical control system and architecture, which is applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc. It can solve the problem that the realization method of the networked architecture of the numerical control system has not been reported, and it is difficult to ensure timely response of real-time tasks and non-real-time tasks. Problems such as long waiting time, to achieve the effect of alleviating data packet conflict and network congestion, avoiding long waiting time, and reducing network transmission delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

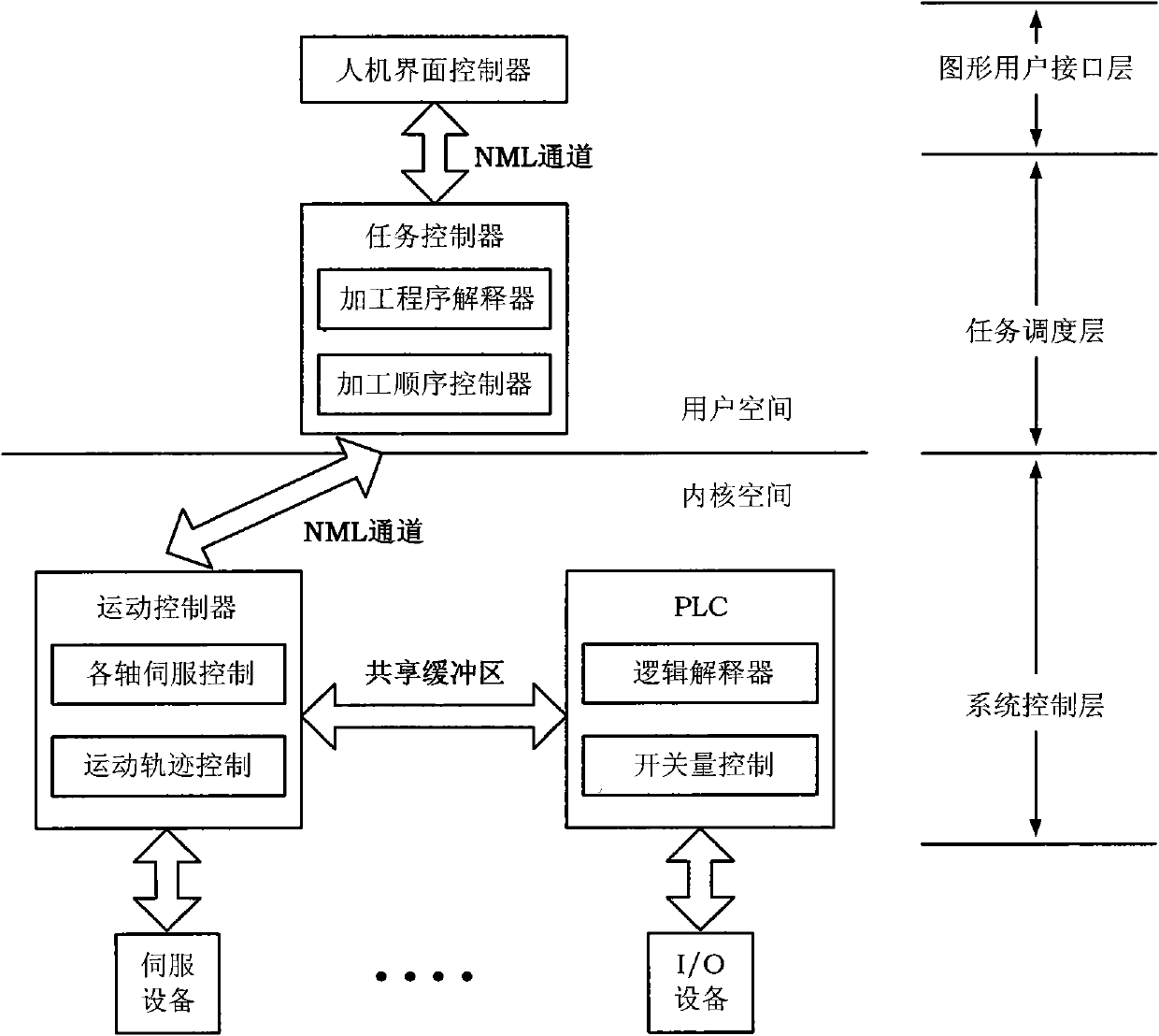

[0051] Such as figure 1 As shown, it is a logical structural diagram of the numerical control system software applied by the method of the present invention.

[0052] The software in the figure runs on the hard real-time multitasking operating system (RTAI, Real Time Application Interface for Linux) platform, adopts the hierarchical reference model design of the real-time control system (RCS, Real-timeControl System) and realizes it based on the RCS library, which can It is divided into three levels and four functional modules. The three levels are: Graphical User Interface Layer, Task Scheduling Layer, and System Control Layer. The four functional modules are man-machine interface controller, task controller, motion controller, and programmable logic controller (PLC, Programmable Logic Controller), which respectively complete the following functions:

[0053] 1. Man-machine interface controller

[0054] As a non-real-time task, it runs in the user space and is a platform f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com