Storage battery production data acquiring device and controlling method thereof

A technology for production data and collection devices, applied in the field of battery production data collection devices, can solve problems such as full utilization of unfavorable production resources, prone to errors, battery smuggling, etc., to prevent smuggling of goods from disrupting the market, improve production efficiency, and realize dynamic management effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following describes the technical solution of the present invention in detail through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

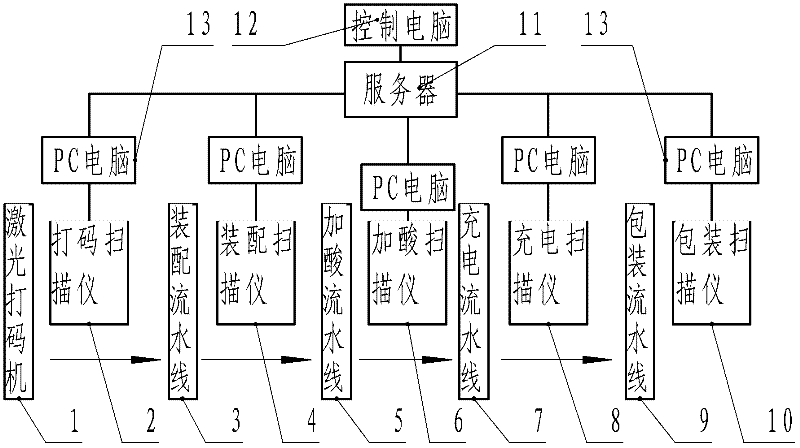

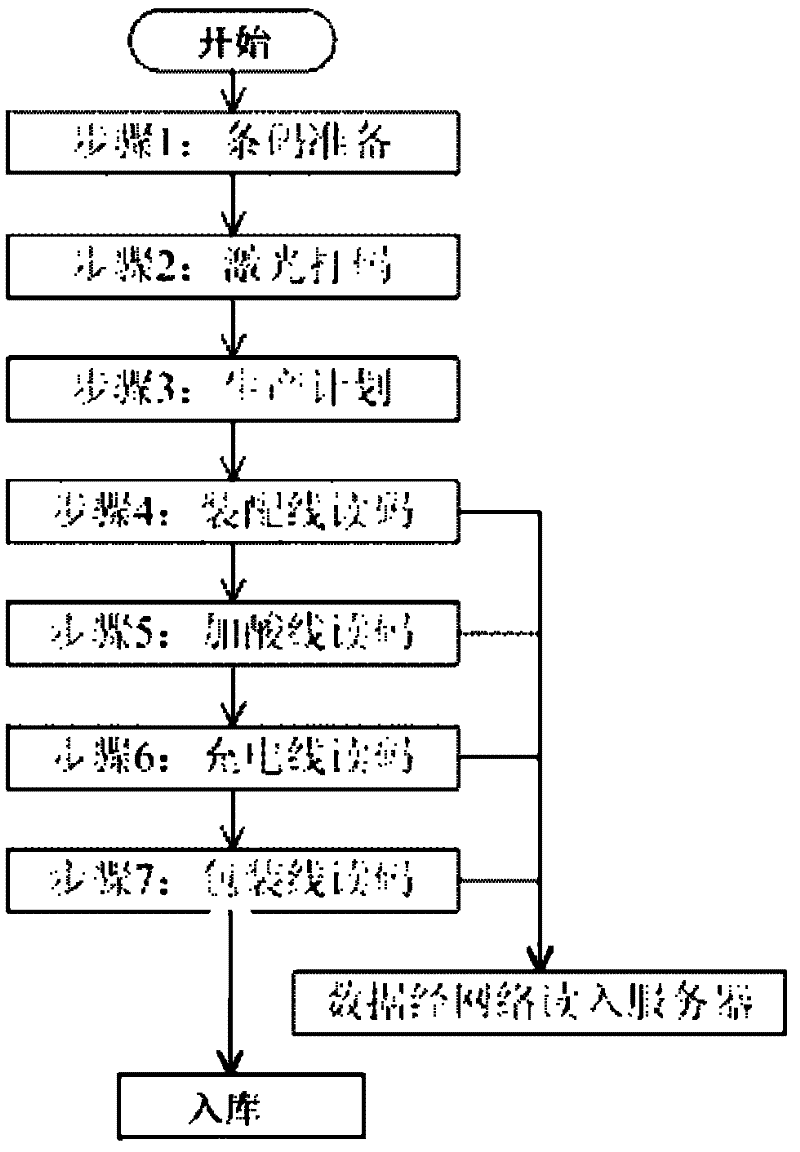

[0030] Such as figure 1 As shown, a storage battery production data acquisition device includes a laser coding machine 1, a coding scanner 2, an assembly line 3, an assembly scanner 4, an acid addition line 5, an acid addition scanner 6, a charging line 7, and a charging scanning Instrument 8, packaging line 9 and packaging scanner 10, coding scanner 2 is set at the product output end of laser coding machine 1, assembly scanner 4 is set at the product output end of assembly line 3, and acid adding scanner 6 is set at The product input end of the acid adding line 5, the charging scanner 8 is set at the product output end of the charging line 7, the packaging scanner 10 is set at the product output end of the packaging line 9, the codi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com