Organic light emitting diode (OLED) display driving chip and display

A technology of display driver and driver chip, applied in static indicators, instruments, electric solid devices, etc., can solve the problem that the driver chip cannot meet the needs of different placement positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above-mentioned features and advantages of the present invention more comprehensible, exemplary embodiments are given below together with accompanying drawings and described in detail as follows.

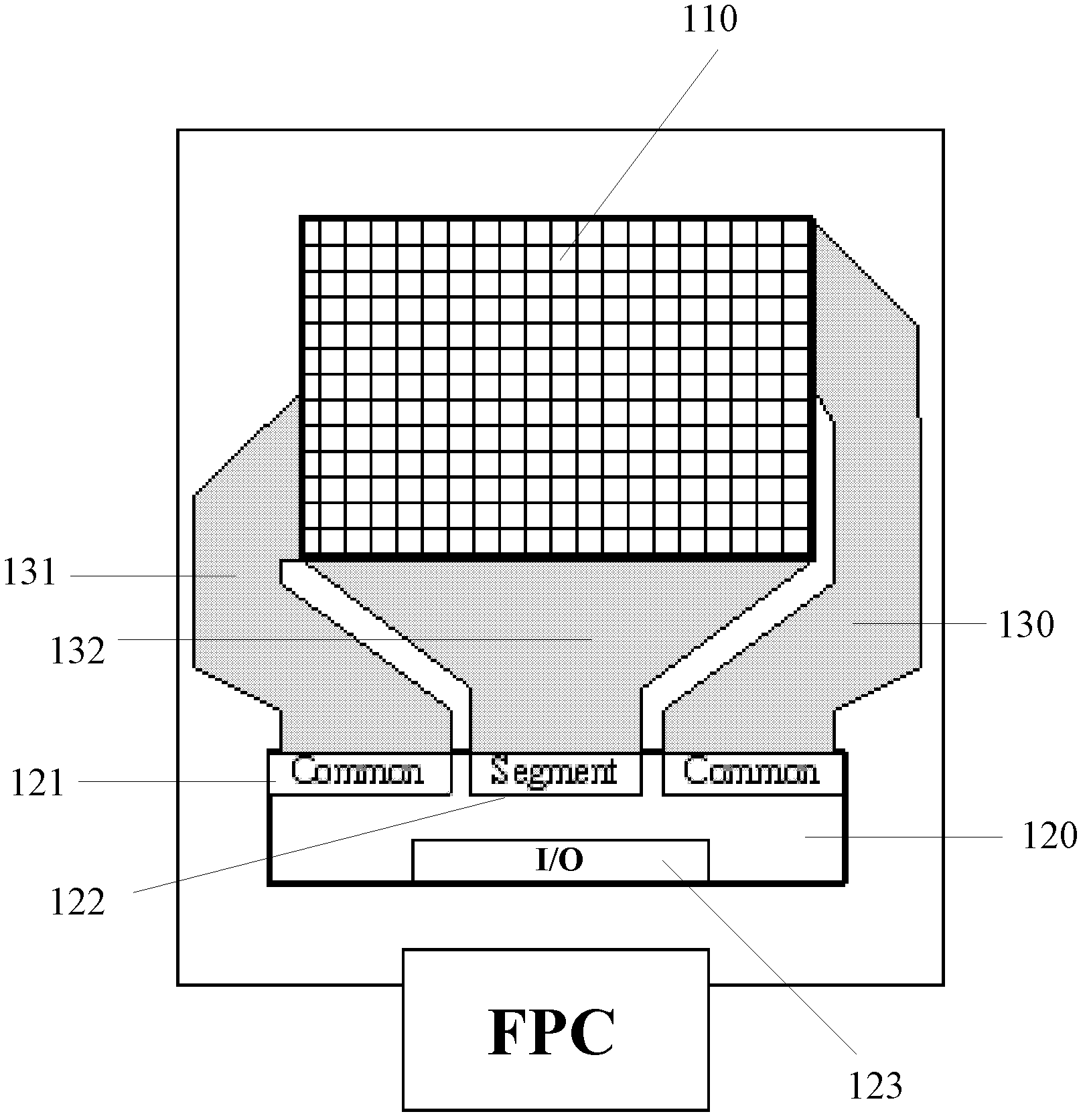

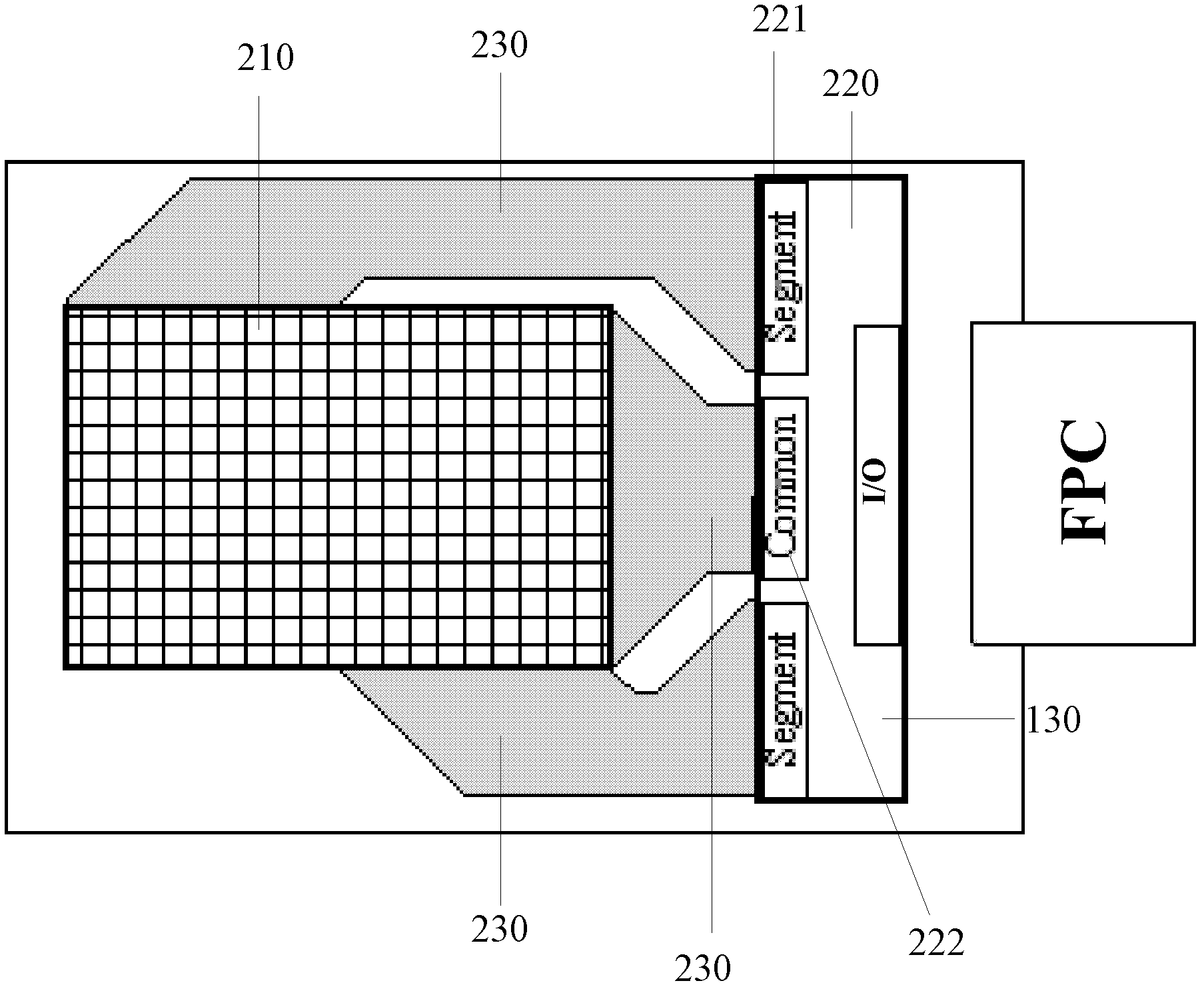

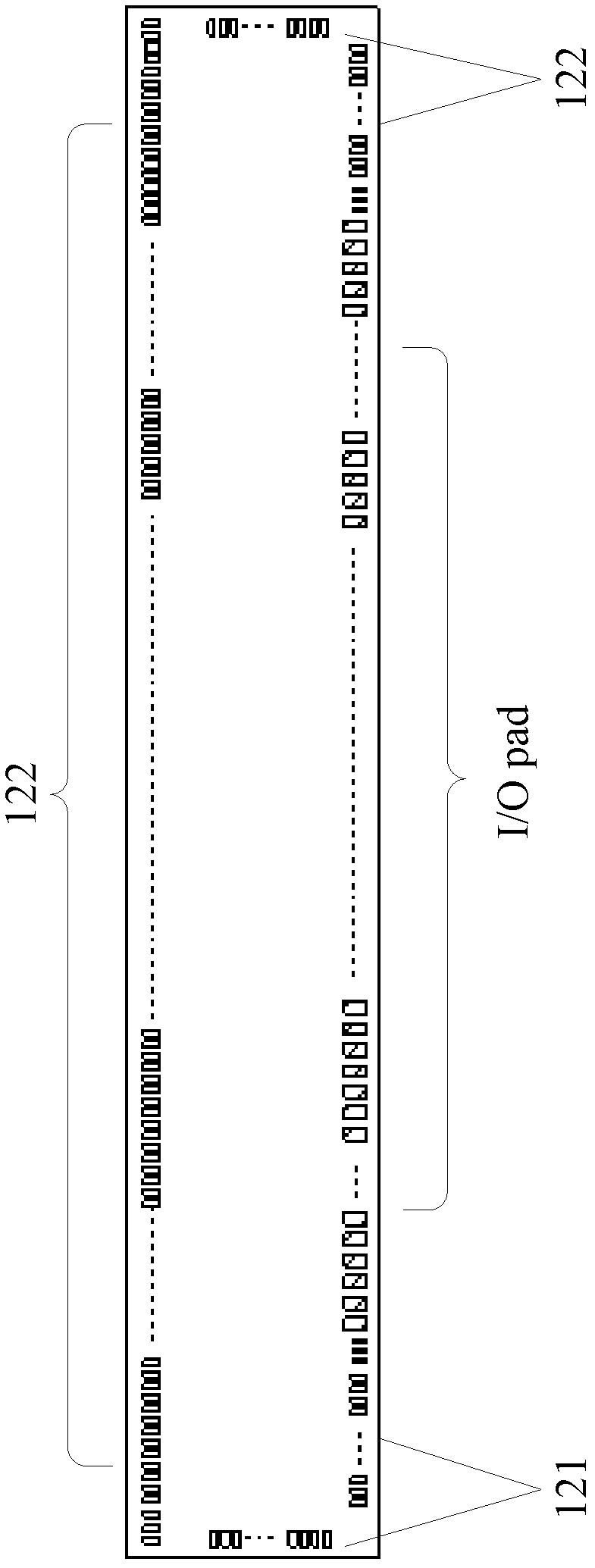

[0022] Considering the different layouts of organic light-emitting diode (OLED) display driver chips in practical applications, the present invention redesigns the chip port so that one chip can be applied to different layouts of OLED screens. Specifically, a set of common drive ports (Common ports) is added to the chip to select different ports for wiring in different placement methods, so that different placement requirements of OLED screens can be met without two chip designs. The specific structure and implementation principle are described through the following embodiments.

[0023] Please refer to Figure 5 , which is a schematic structural diagram of an OLED display driver chip provided by an embodiment of the present invention. As shown in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com