Flexible laminated bus bar

A laminated busbar, flexible technology, applied in the direction of rod/rod/wire/strip conductor, contact parts, fixed/insulated contact members, etc., can solve the problem of reducing inductance between two poles, reducing copper utilization, frequent thermal expansion, etc. problems, to eliminate the influence of loose connections, improve connection stability, and improve shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

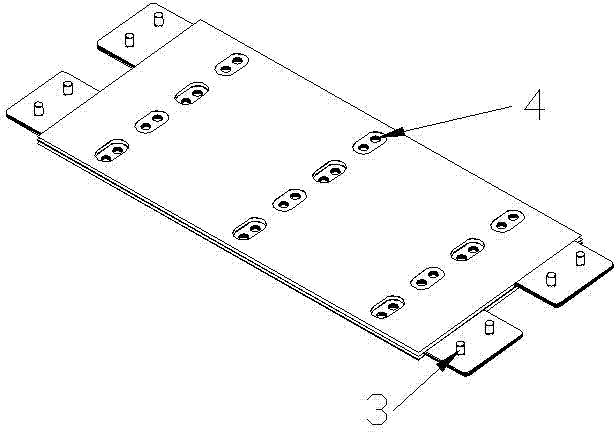

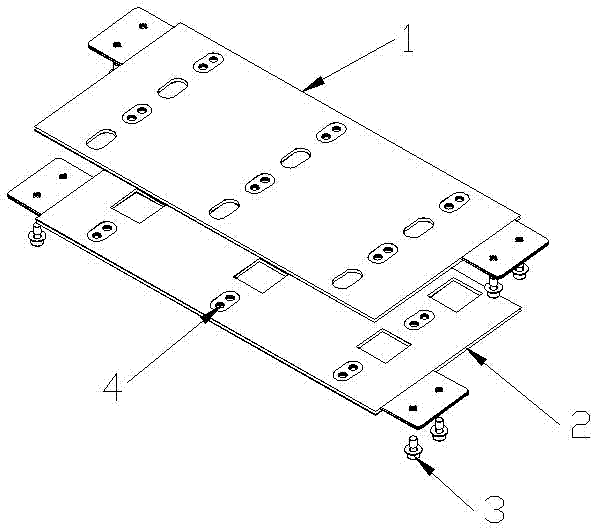

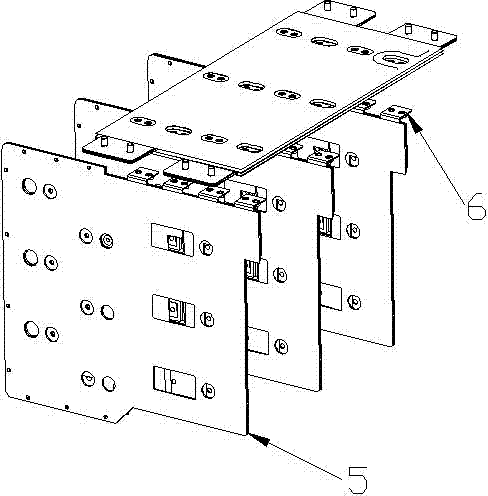

[0018] Such as figure 2 As shown, the flexible laminated bus bar described in this embodiment includes a positive copper bar 1, a negative copper bar 2, a butterfly gasket 7 connecting the two copper bars, and a modified screw 3, such as Figure 4 As shown, the positive electrode copper bar 1 and the negative electrode copper bar 2 are all composed of a number of thin sheet copper plates 8 superimposed and combined, and each group of thin sheet copper plates 8 is respectively fixed and connected by restructured screws 3 to form the required copper bars. Butterfly gaskets 7 are provided on the connection surface between the screw 3 and the copper bar, and a bus bar connection installation hole 4 is provided on the surface of the positive copper bar 1 and the negative electrode copper bar 2 oppositely, and the bus bar connection installation hole 4 is used for connecting The laminated bus bar 5, the positive copper bar 1 and the negative copper bar 2 are relatively superimposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com