Frequency converter stopping device

A technology of stopping device and frequency converter, applied in the field of frequency converter, can solve the problems of brake control failure, sudden start of the motor, affecting the service life of the production efficiency frequency converter, etc., and achieve the effect of preventing abnormal start and ensuring personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make those skilled in the art more clearly understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

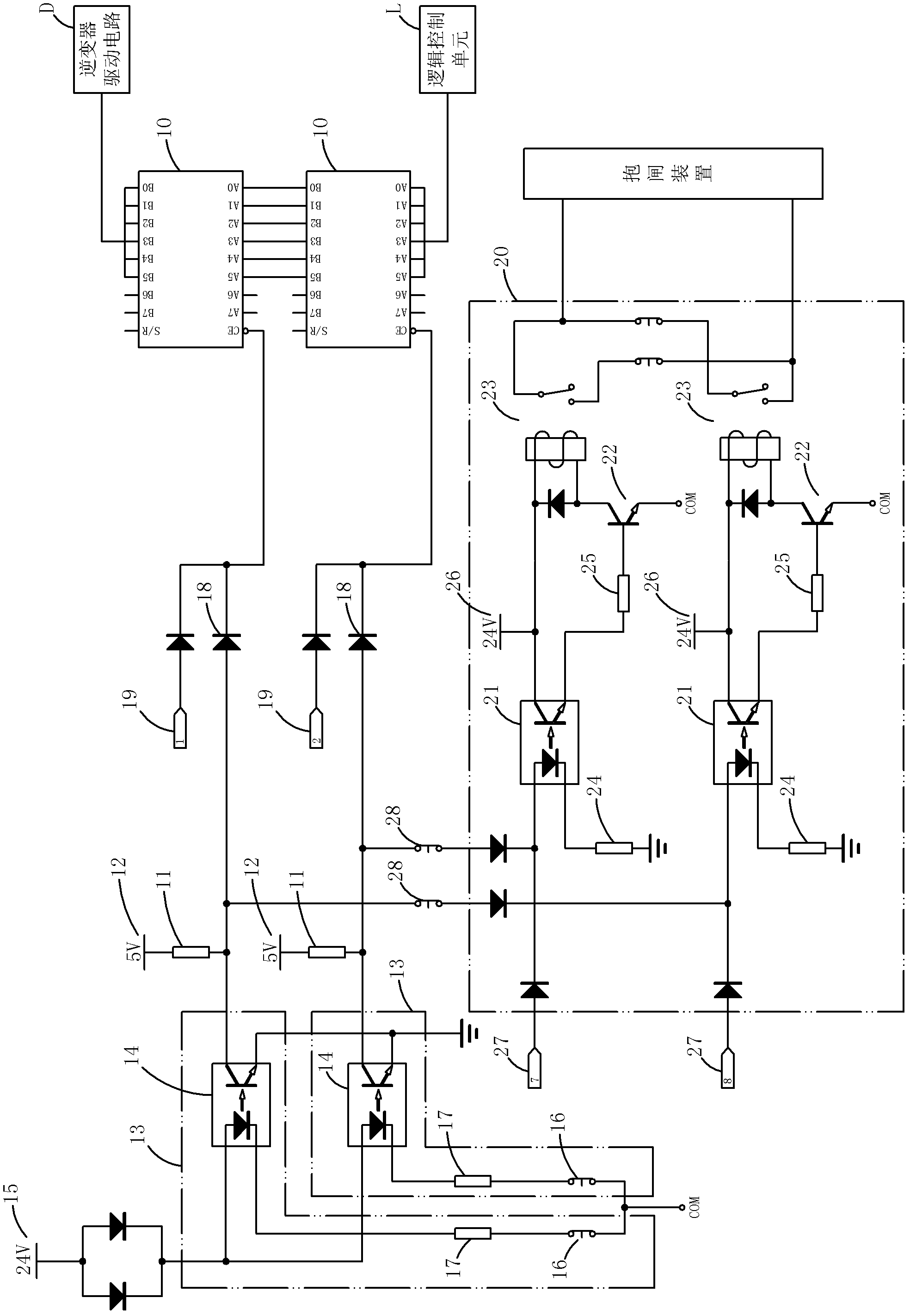

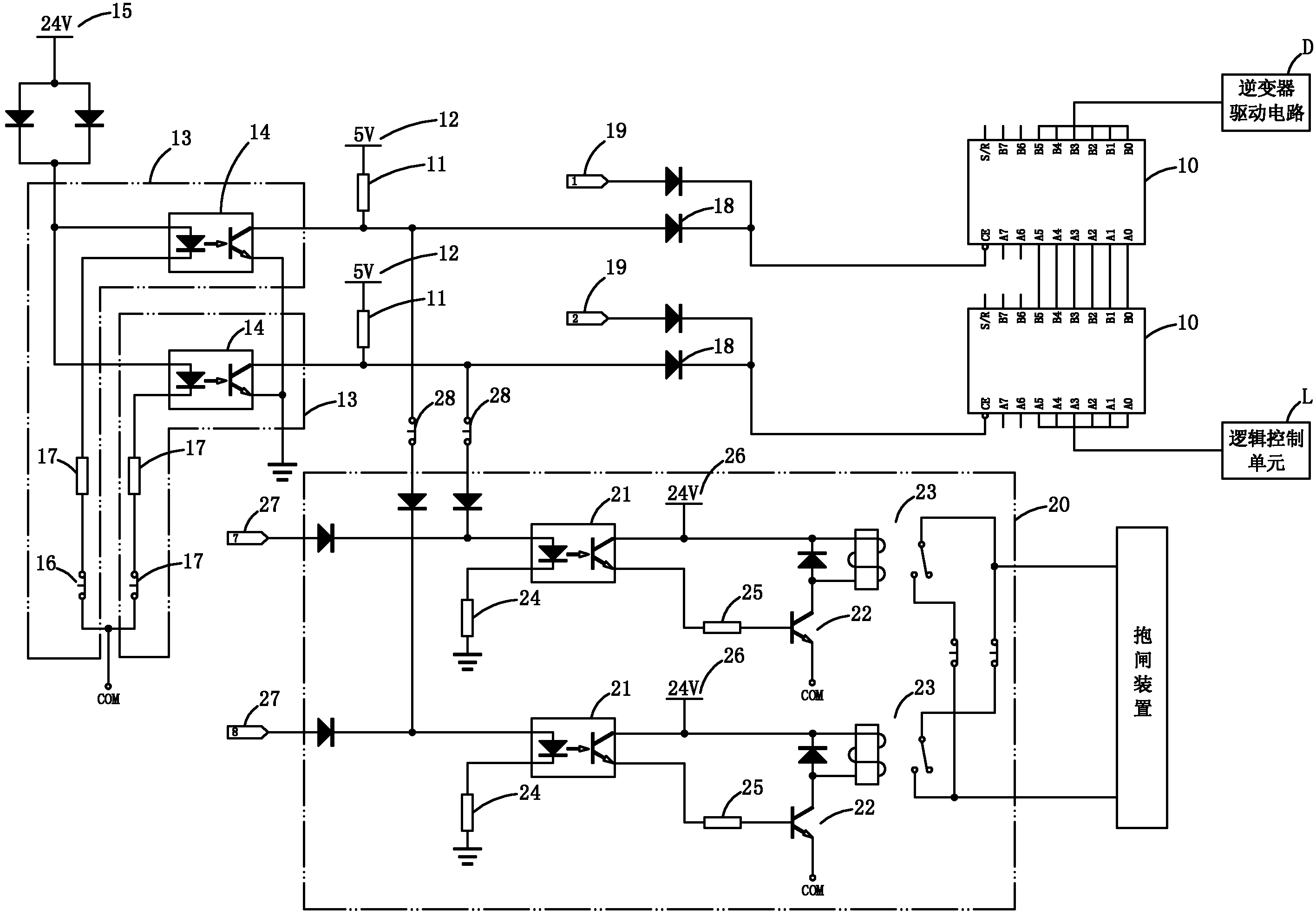

[0019] The frequency converter stopping device disclosed in the present invention can be applied to production equipment such as cutting machines, numerically controlled lathes, etc., to reliably stop the operation of the frequency converter. refer to figure 1 As shown, the frequency converter shutdown device includes two buffers 10, and the two buffers 10 are connected in series to the logic control unit L (such as a DSP microprocessor) and the inverter drive circuit D (such as an IGBT drive optical In this way, by controlling the enable of any buffer 10 to be invalid, cutting off the driving signal sent from the logic control unit L to the inverter driving circuit D, turning off the switching device of the inverte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com