IGBT non-contact lifting electromagnet control system for non-rectifying transformer

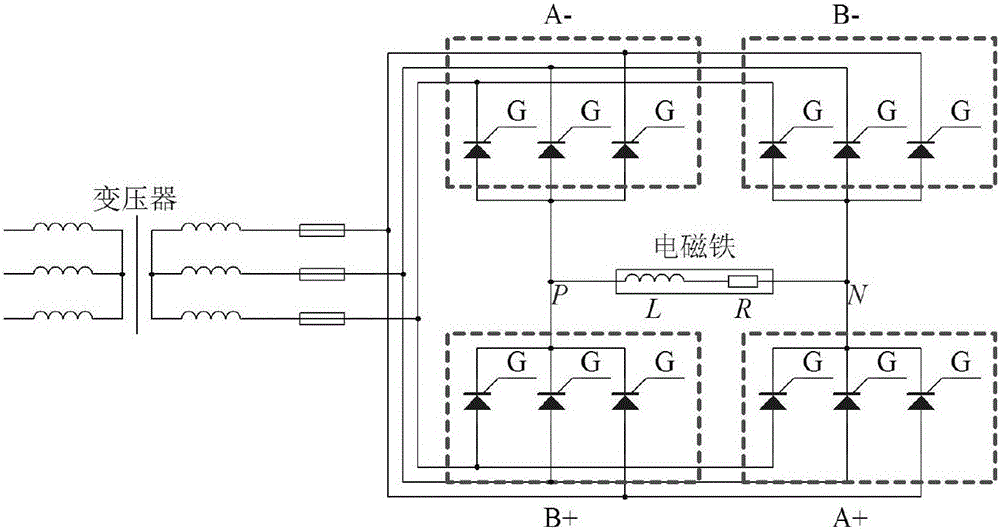

A technology for lifting electromagnets and rectifier transformers, applied in electromagnets, electromagnetic circuit devices, etc., can solve problems such as overvoltage, and achieve the effects of saving purchase funds, light weight, and simple and convenient chain control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

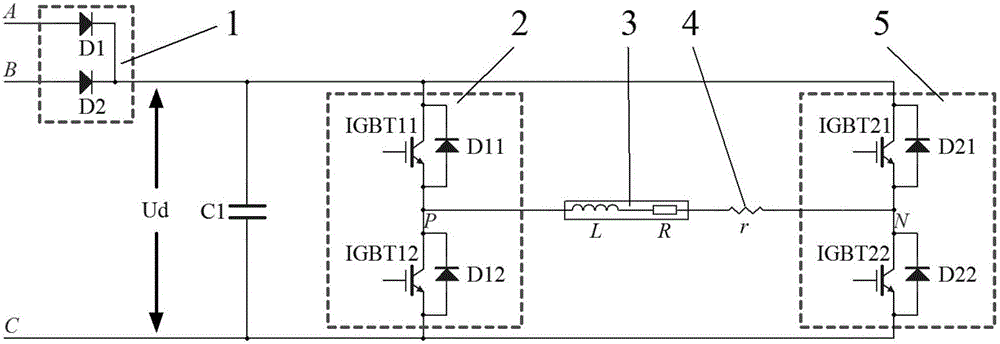

[0042] Specific embodiment 1: IGBT contactless lifting electromagnet control system without rectifier transformer, the main circuit includes diode module 1, insulated gate bipolar transistor module 12, insulated gate bipolar transistor module 25, capacitor C1, electromagnet 3 and shunt r4; the diode module 1 includes two diode elements, which are diode D1 and diode D2, and diode D1 and diode D2 are connected in parallel; the insulated gate bipolar transistor module 12 includes two IGBT elements, respectively IGBT11 and IGBT12, IGBT11 and IGBT12 are connected in series; the IGBT11 is connected in anti-parallel with a diode D11, the IGBT12 is connected in anti-parallel with a diode D12, and the insulated gate bipolar transistor module 25 includes 2 IGBT elements, respectively IGBT21 and IGBT22 ; IGBT21 and IGBT22 are connected in series, IGBT21 has a diode D21 in anti-parallel, IGBT22 has a diode D22 in anti-parallel,

[0043] One end of the insulated gate bipolar transistor mod...

specific Embodiment 2

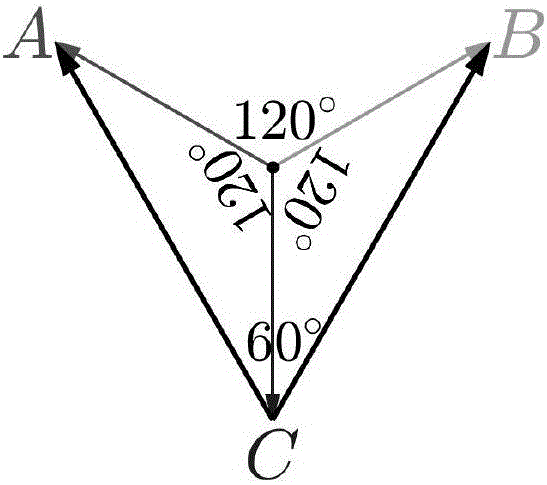

[0054] combine figure 2 As shown, connect the 380V three-phase alternating current U A , U B and U C In the access circuit, after being rectified by diodes D1, D2 and capacitor C1, a pulsating DC voltage U with a period of 20ms is obtained d , in the main circuit U will be C as the reference voltage, so U AC and U BC is the phase difference of 60°, the effective value is 380V AC, such as image 3 shown; if the energy storage effect of capacitor C1 is ignored, the effective value of the pulsating DC voltage rectified by diodes D1 and D2 As shown in formula (1), the waveform diagram is as follows Figure 4 shown;

[0055] U ¯ d = 2 2 π ∫ 0 2 π / 3 380 2 · s i n θ d θ = 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com