Sports ball and manufacturing method thereof

A technology for sports balls and manufacturing methods, which is applied in the field of sports balls, can solve the problems of low production efficiency, inability to maintain, and encounters with indoor buildings, and achieve the effects of improving production efficiency, preventing ball deformation, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Embodiments of the present invention are described in detail as follows with accompanying drawing:

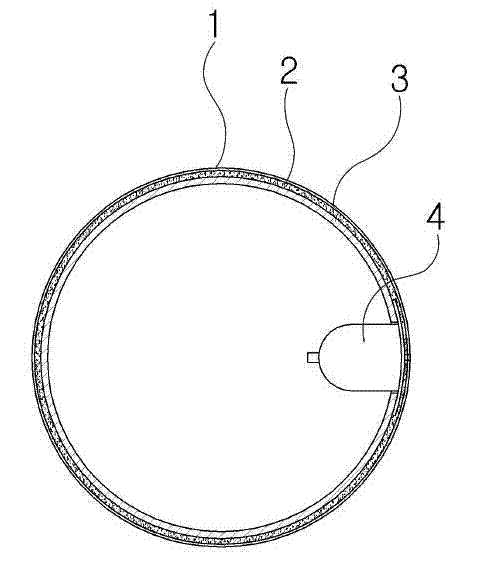

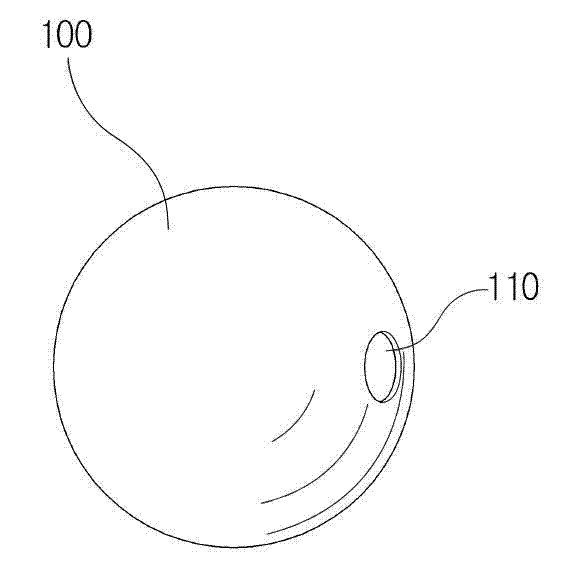

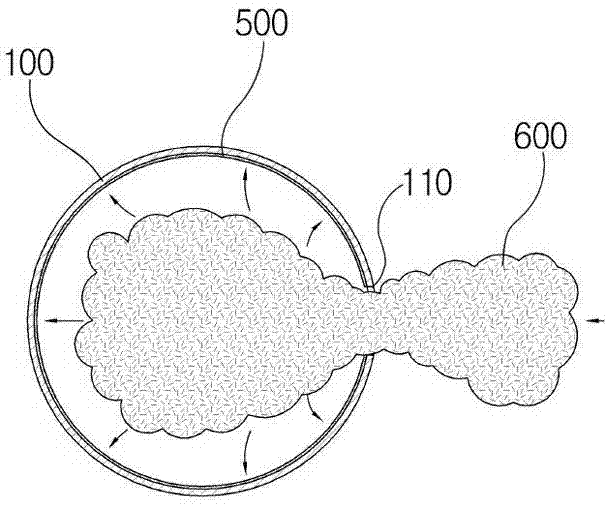

[0059] Such as figure 2 As shown in the figure, the balloon 100 with valve insertion port 110 is provided on the outer surface of one spherical side, and figure 2 As shown in the figure, there is a valve insertion port 110 on the balloon 100 , and the valve 200 is provided in the balloon 100 , and a plurality of polygonal skin sheets 400 can be provided on the outside of the balloon 100 .

[0060] The polygonal skin sheet 400 is as Figure 7 As shown in the figure, the outer surface of the polygonal skin 400 has an outer skin 410 bent along the direction of the knitted reinforcement 300 , and the inner surface of the outer skin 410 has an elastic body 420 . Moreover, the inner side of the edge of the elastic body 420 is formed with a bottom surface (431) along the edge at a certain depth. A folding groove 430 is formed.

[0061] The height of the folding surface 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com