Three-stage, one-closed-circuit, two-stage pre-selection crushing new process

A new process, closed-circuit technology, applied in the field of three-stage, one-closed-circuit, two-stage pre-selection and crushing new process, can solve the problems of increasing mineral processing costs, fine particles cannot be separated, and cannot meet the grinding grade, so as to improve ore grade and reduce The effect of reducing the amount of grinding and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

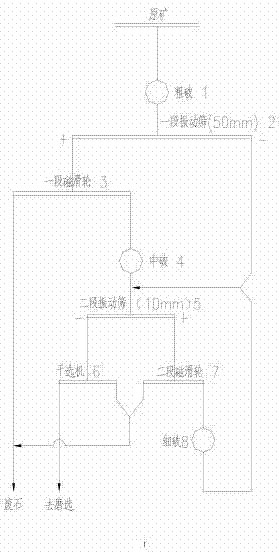

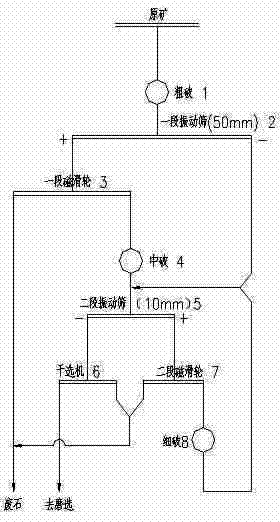

[0019] The specific implementation of the present invention will be described below with reference to the embodiments of the drawings.

[0020] Such as figure 1 As shown, a new three-stage, one-closed-circuit, two-stage preselection crushing process of the present invention is characterized by including the following steps:

[0021] 1) The raw ore with Mohs hardness above 7 is sent to the coarse crusher for coarse crushing, and the coarse crusher discharges into a vibrating screen for classification.

[0022] 2) After being classified by a vibrating screen, the products on the screen enter a magnetic pulley,

[0023] 3) The concentrate separated by a magnetic pulley enters the middle crusher for crushing, and the separated waste rock enters the waste rock bin.

[0024] 4) The products from the middle crusher and the under-screen products from the first vibrating screen enter the second vibrating screen together.

[0025] 5) The products on the second-stage vibrating screen enter the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com