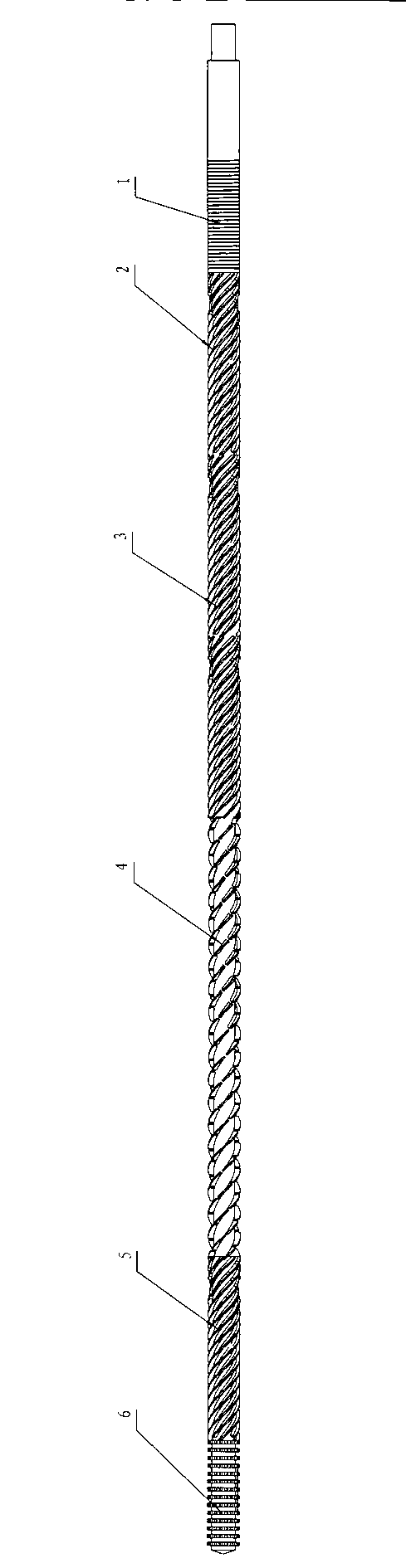

CO2 multi-component cooperative foaming and combined cooling screw rod

A mixed cooling and multi-component technology, applied in the field of plastic processing equipment for polymer materials, can solve problems such as low pressure, abnormal and stable production, and large shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Referring to the accompanying drawings, the diameter of the screw body is 156mm, and the screw body is sequentially composed of a leak-proof section 1, a pressurized section 2, a low-shear section 3, a large-lead multi-thread reverse grooved return section 4, and a strong cooling and mixing section from back to front. 5 and multi-thread slotted strong mixing section 6; among them, the leak-proof section 1 is a single-head external thread body with a pitch of 10mm and a groove depth of 2mm; the booster section 2 is a 4-8-head external thread with a lead of 200-400mm body; low-shear section 3 is a 440-700mm lead with 6-10 heads of external thread body; large-lead multi-thread reverse slotted return section 4 is a 440-700mm lead with 3-6 heads of external thread body , the thread of the large-lead multi-thread reverse slotting return section 4 is provided with 2-3 head reverse thread grooves with a width of 25mm and a lead of 400-700mm; the strong cooling mixing section 5 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com