A kind of pretreatment method for increasing the viscosity of xanthan gum product

A xanthan gum and pretreatment technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of rare reports on the application process of xanthan gum fermentation liquid, and achieve low cost, easy operation, and improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

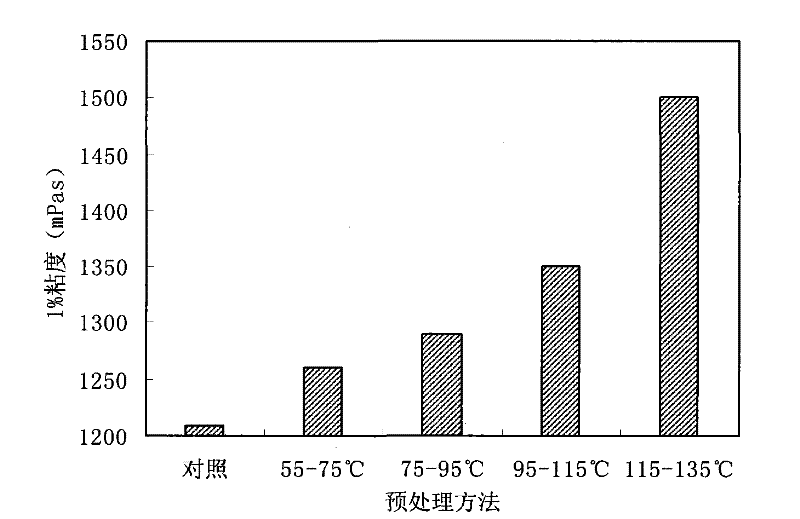

[0030] A kind of pretreatment method that increases the viscosity of xanthan gum product, concrete experimental technological process is as follows:

[0031] (1) Preparation of xanthan gum fermentation broth:

[0032] Use 4% corn starch, 0.5% soybean powder, 0.3% calcium carbonate, and the rest as water as the fermentation medium, and ferment with ventilation and stirring for 65 hours under the conditions of pH 7.0 and temperature 28°C, stop stirring and temperature control, and collect after fermentation fermentation broth;

[0033] (2) Fermentation broth pretreatment:

[0034] The obtained xanthan gum fermentation broth is heated up so that the temperature of the fermentation broth rises to within the range of 75°C, and the fermentation broth is stirred for 30 minutes within this temperature range, and after the treatment is completed, the fermentation broth is cooled to 25°C for extraction;

[0035] (3) Xanthan gum extraction:

[0036] According to the volume of xanthan ...

Embodiment 2

[0038] A kind of pretreatment method that increases the viscosity of xanthan gum product, concrete experimental technological process is as follows:

[0039] (1) Preparation of xanthan gum fermentation broth:

[0040] Use 6% corn starch, 1% bean flour, 0.7% calcium carbonate, and the rest as water as the fermentation medium, ventilate and stir for 70 hours under the conditions of pH 7.0 and temperature 30°C, stop stirring and temperature control, and collect after fermentation fermentation broth;

[0041] (2) Fermentation broth pretreatment:

[0042]The obtained xanthan gum fermentation broth is heated up so that the temperature of the fermentation broth rises to within the range of 85°C, and the fermentation broth is stirred for 45 minutes within this temperature range, and after the treatment is completed, the fermentation broth is cooled to 30°C for extraction;

[0043] (3) Xanthan gum extraction:

[0044] According to the volume of the xanthan gum fermentation liquid, a...

Embodiment 3

[0046] A kind of pretreatment method that increases the viscosity of xanthan gum product, concrete experimental technological process is as follows:

[0047] (1) Preparation of xanthan gum fermentation broth:

[0048] Use 6% corn starch, 2% soybean powder, 1% calcium carbonate, and the rest as water as the fermentation medium, ventilate and stir for 75 hours at pH 7.0 and temperature 32°C, stop stirring and temperature control, and collect after fermentation fermentation broth;

[0049] (2) Fermentation broth pretreatment:

[0050] The obtained xanthan gum fermentation broth is heated up so that the temperature of the fermentation broth rises to within the range of 95°C, and the fermentation broth is stirred for 60 minutes within this temperature range, and after the treatment is completed, the fermentation broth is cooled to 35°C for extraction;

[0051] (3) Xanthan gum extraction:

[0052] According to the volume of the xanthan gum fermentation liquid, add 5 times the vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com