New catalytic hydroprocessing thermal cracking-hydrotreating process of high-sulfur high-acid inferior heavy oil

A catalytic thermal cracking and hydrotreating technology, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, can solve problems such as poor economy, low economic return rate, and small space velocity of fresh raw materials, and achieve The dispersion process is simple and feasible, the dispersion process is simple and easy, and the effect of excellent product properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

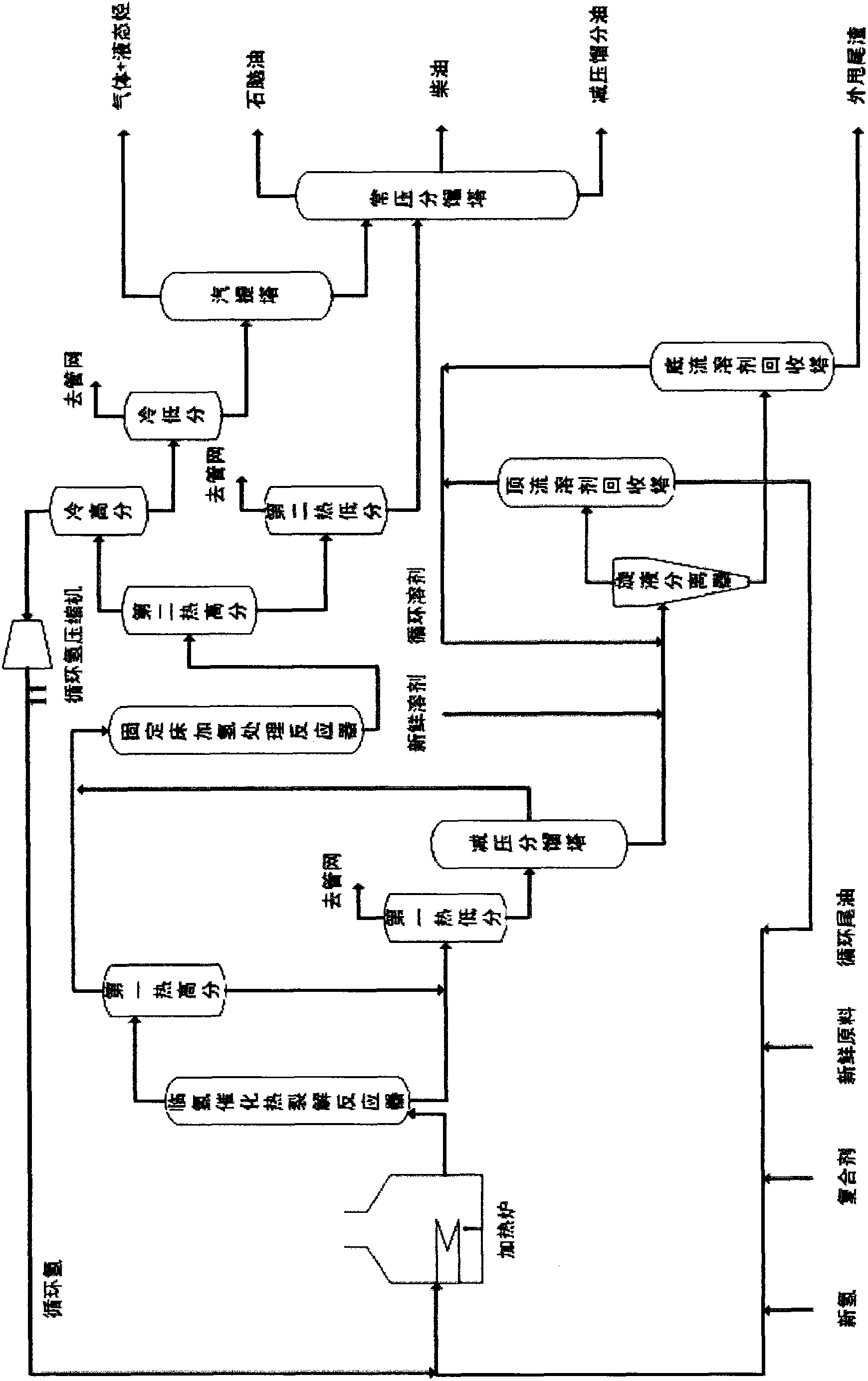

[0027] The new process of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. In actual design and operation, the designer of the present invention adopts the technological process as shown in the accompanying drawing, and fresh raw material, circulating tail oil and oil-soluble compound agent are mixed through multistage surge tank and multistage static mixer, and this mixing The method can ensure that a small amount of compounding agent is evenly dispersed in a large amount of raw materials. The mixture is then mixed with fresh hydrogen and circulating hydrogen and enters the heating furnace. After being heated by the heating furnace to 425-455°C, it enters the hydrogen catalytic pyrolysis reactor from the bottom. Under the conditions of reaction pressure 10-20MPa and reaction temperature 425-455°C The hydrogen-catalyzed thermal cracking reaction is carried out, and the higher reaction temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com