Organic-inorganic composite emulsion for coating and preparation method of organic-inorganic composite emulsion

An inorganic composite and emulsion technology, applied in the field of coatings, can solve the problems of complex preparation process, difficult dispersion, poor stability, etc., and achieve the effect of solving unstable agglomeration, long-term antibacterial effect, and simplifying the dispersion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

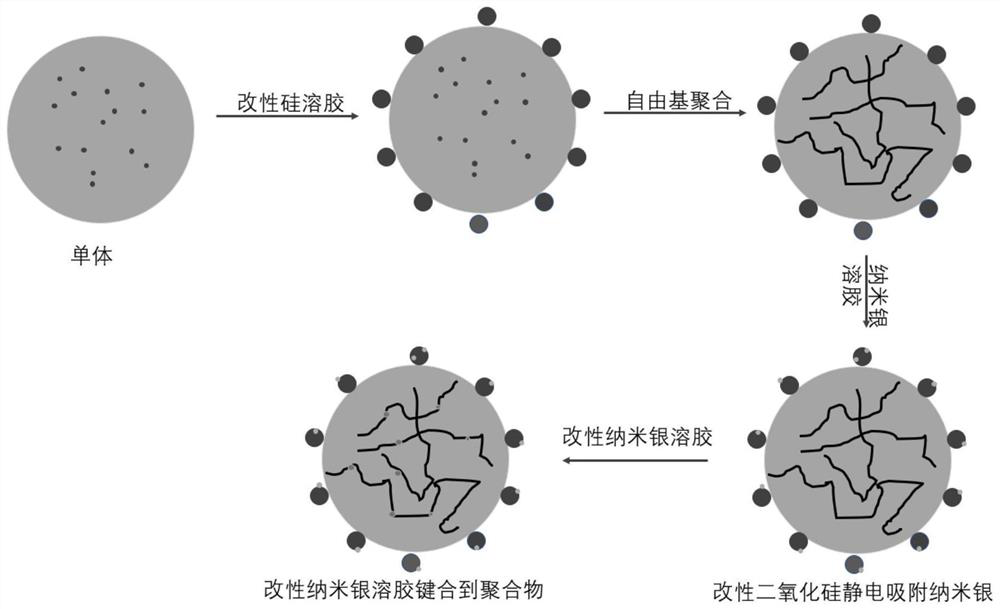

[0046] A kind of preparation method of organic-inorganic composite emulsion for coating, such as figure 1 As shown, the specific steps are as follows:

[0047] A. Preparation of modified silica sol

[0048] Add 0-50g of deionized water to 10-100g of silica sol, stir well, then add 0.2-5g of silane coupling agent KH560, stir at 55°C for 5h to obtain modified silica sol;

[0049] B, Preparation of Pickering emulsion

[0050] Using hydrophobically modified silica sol, monomers and initiators to form stable Pickering emulsions under high-speed dispersion and ultrasonic conditions, and prepare silica acrylic emulsions by free radical polymerization;

[0051] Concrete preparation process is as follows:

[0052] B1. Add 1-30g of modified silica sol into 170-199g of deionized water, stir and mix evenly, and make 200g of silica sol solution;

[0053] B2. Add the monomer to the silica sol solution, wherein the monomer is: 1-5g acrylic acid, 0-60g methyl methacrylate, 0-50g butyl acr...

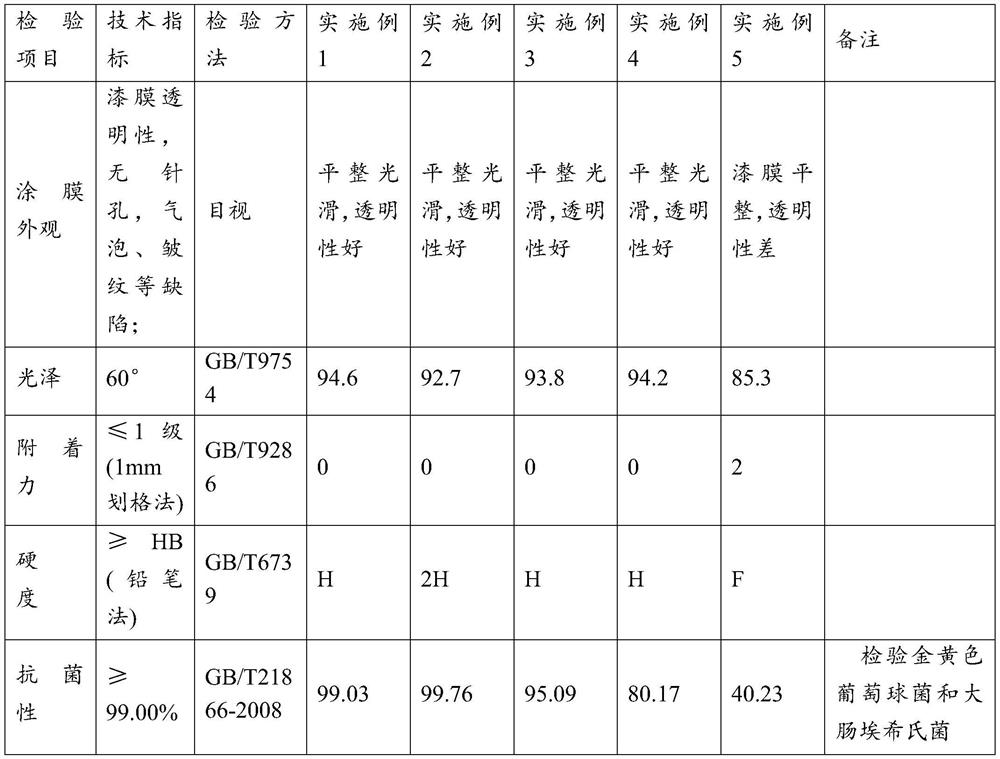

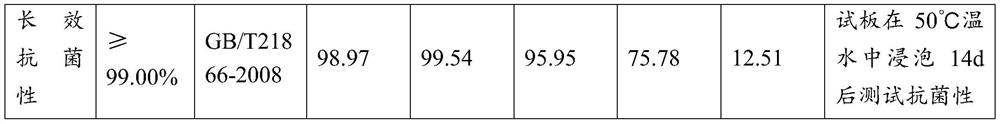

Embodiment 1

[0066] A. Preparation of modified silica sol

[0067] Add 30g of deionized water to 50g of commercial silica sol (particle size: 20nm, solid content: 30%, pH: 4-6), after fully stirring, add 1g of silane coupling agent KH560, stir at 55°C for 5h, A modified silica sol is obtained.

[0068] B, Preparation of Pickering emulsion

[0069] Using hydrophobically modified silica sol, acrylic acid monomer and oil-soluble initiator to form a stable Pickering emulsion under high-speed dispersion and ultrasonic conditions, and preparing silica acrylic emulsion by thermal initiation;

[0070] Concrete preparation process is as follows:

[0071] B1. Add 10g of hydrophobically modified silica sol to 190g of deionized water, stir and mix evenly, and make 200g of silica sol solution;

[0072] B2. Mix 3g acrylic acid, 50g methyl methacrylate, 35g butyl acrylate, 12g isooctyl acrylate and 0.5g AIBN to prepare a mixture. Under high-speed dispersion conditions, 4000rpm, Shanghai Tianchen high-...

Embodiment 2

[0080] Compared with Example 1, the main difference of Example 2 is that the addition of hydrophobically modified silica sol in the B step is increased to 50g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com