Dumbbell microporous spinneret

A spinneret, dumbbell-shaped technology, used in filament/thread forming, textile and papermaking, fiber processing, etc., can solve the problems of increased end breakage, more wool in finished products, and more filaments injected, so as to increase the number of special shapes. high degree of stability, low cost, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

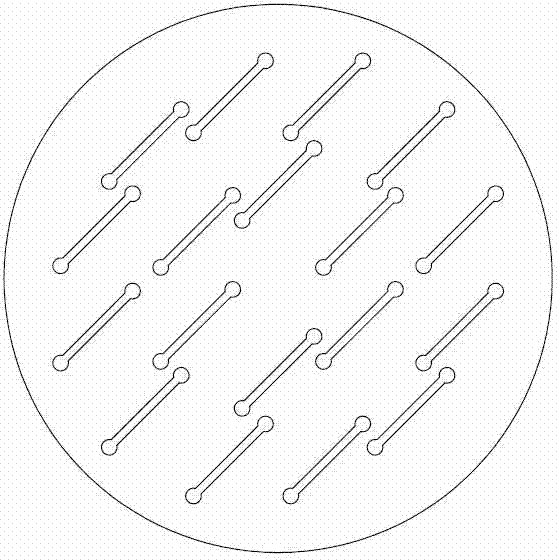

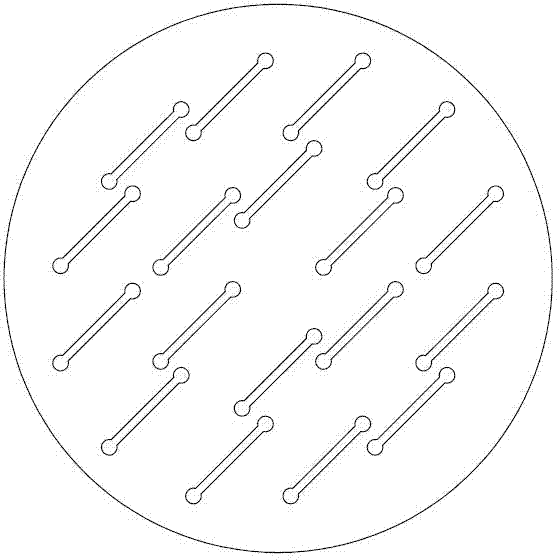

[0017] like figure 1 As shown, a dumbbell-shaped microporous spinneret includes a spinneret and a spinneret hole. There are 12-38 spinneret holes on the spinneret, and the shape of the spinneret holes is dumbbell-shaped. When the spinneret holes are arranged on the spinneret, the angle range between the similar long sides of the spinneret holes and the horizontal direction is The spinneret holes on the spinneret are arranged in two circles or three circles on the spinneret; the aspect ratio of the spinneret is 15-20; the radius of the dumbbell head at the two ends of the spinneret is the leaf width of the spinneret hole.

[0018] During specific use, the number of spinneret holes and the aspect ratio of the spinneret holes in the present invention can be determined according to actual needs. like figure 1 As shown, the number of spinneret holes of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com