A warp knitting machine swing adjusting device

A technology of amplitude adjustment and warp knitting machine, which is applied in warp knitting, textiles, papermaking, knitting, etc. It can solve the problems of long processing cycle, single position, waste of financial and material resources, etc., and achieves convenient swing adjustment, simple structure, easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

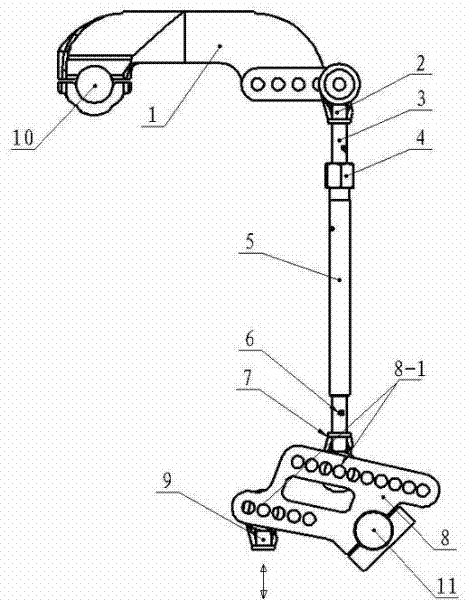

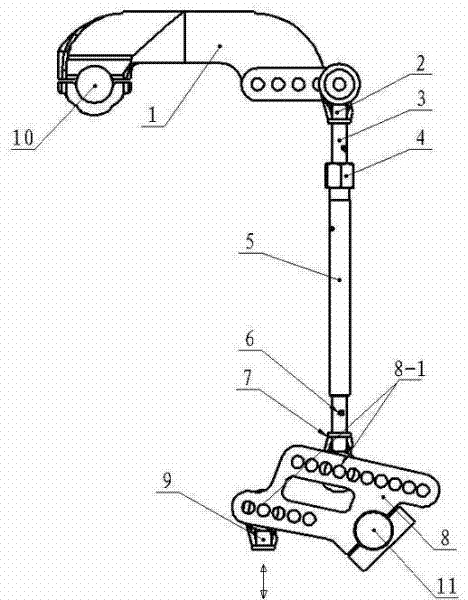

[0012] like figure 1 Shown: the present invention relates to a warp knitting machine swing adjustment device, including the swing upper swing arm 1, connecting head 2, 7, 9, connecting shaft 3, lock nut 4, pull rod 5, adjusting screw rod 6, swing arm 8 and balance shafts 10,11. Among them, the upper swing arm 1 and the swing shaft 10 are fixedly connected by screws, the connecting head 2 is fixedly connected with the swing hole by a connecting piece, one end of the connecting shaft 3 is fixedly connected with the connecting head 2, and the other end is connected with the pull rod 5 through the lock nut 4 Fixedly connected, the two ends of the adjusting screw 6 are fixedly connected with the pull rod 5 and the connecting head 7 respectively, the swing arm 8 is fixedly connected with the swing shaft 11, and the connecting heads 7 and 9 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com